Precise linear displacement apparatus

A linear displacement and precision technology, applied in the direction of electromechanical devices, mechanical energy control, electrical components, etc., can solve the problems of slow response speed, large radial swing, and inaccurate precision, and achieve fast response speed, avoid radial swing, and axis To move the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

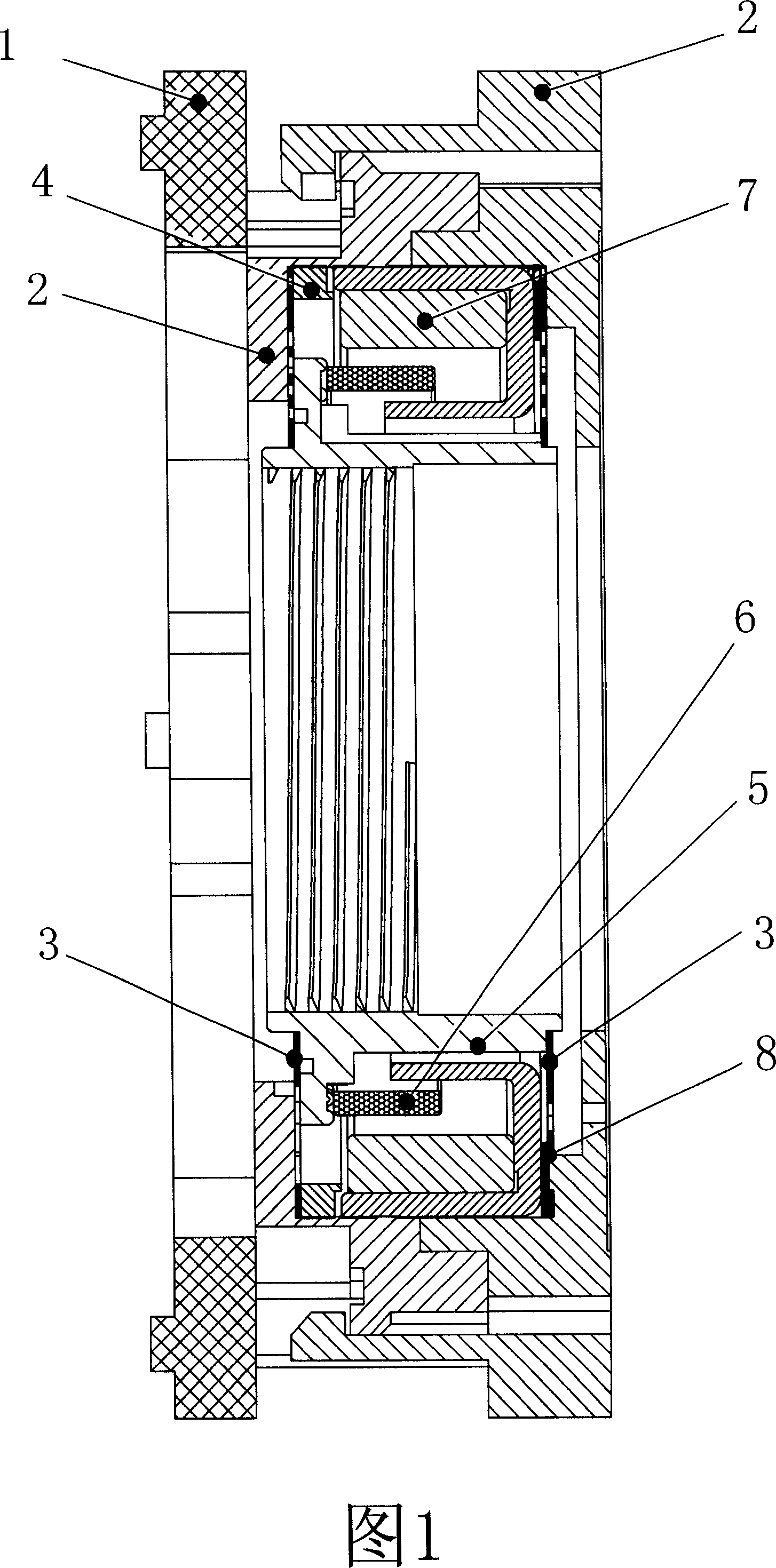

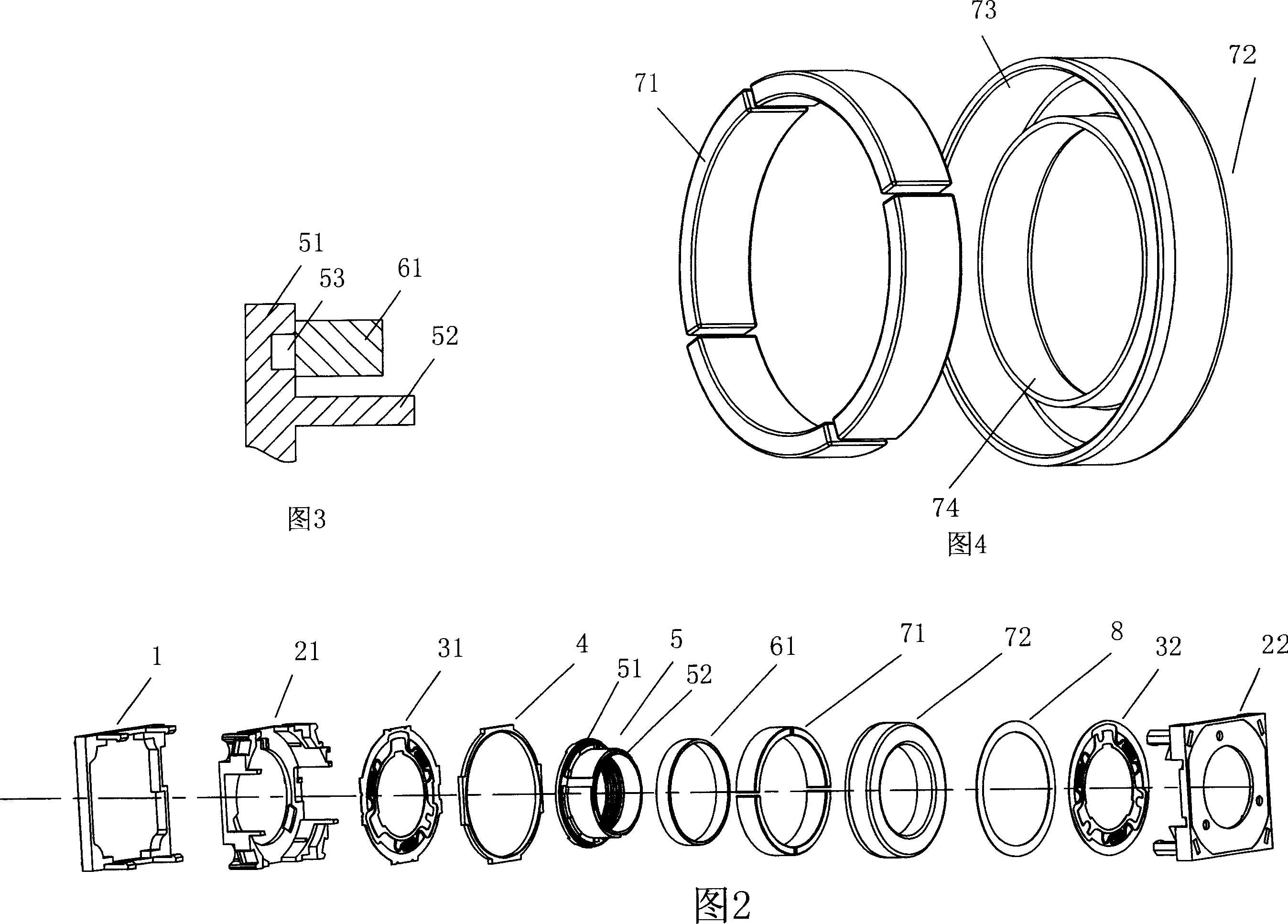

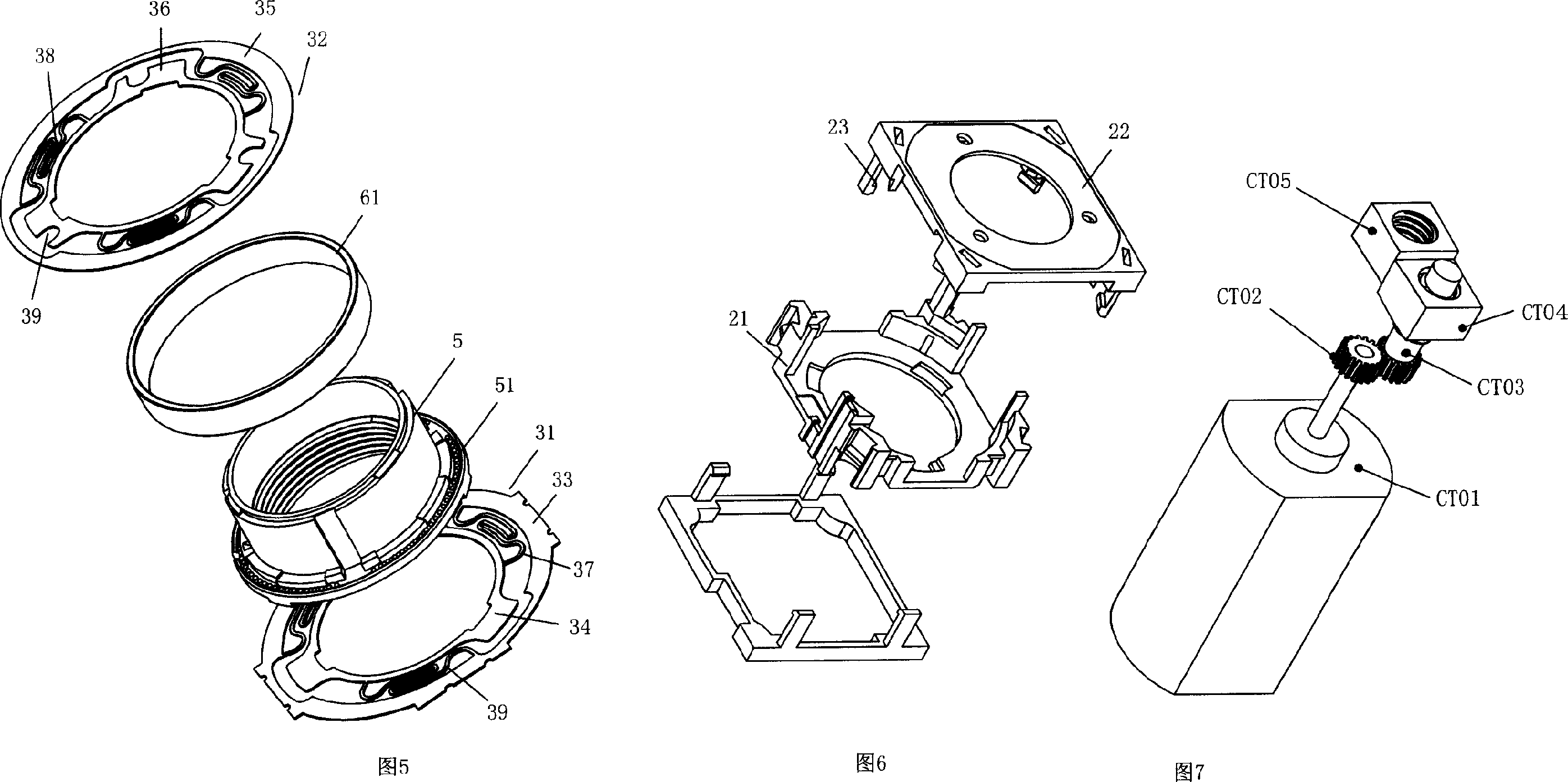

[0022] As shown in Figure 1, the present invention includes: a housing 2, a motion carrier 5, an electromagnetic drive unit 6, a permanent magnet unit 7 and an elastic support seat 3, the permanent magnet unit 7 is arranged in the housing 2, and the motion carrier 5 passes through The elastic support seat 3 is installed in the housing 2, and the electromagnetic drive unit 6 is fixed on the motion carrier 5. When the electromagnetic drive unit 6 is energized, the permanent magnet unit 7 applies a moving load to the electromagnetic drive unit 6 with the elastic support seat 3. The seat 5 acts oppositely, and the electromagnetic drive unit 6 drives the motion carrier 5 to move under the action of the permanent magnet unit 7 .

[0023] The specific embodiments of the present invention will be described below with the aid of the accompanying drawings, in which similar or identical parts are denoted by the same reference numerals.

[0024] As shown in Figures 1 and 2, the electromag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com