Technique for producing polyanionic cellulose with high degree of substitution

A polyanion, high degree of substitution technology, applied in the field of fine chemical production, can solve the problems of increased inhomogeneity of mass transfer and heat transfer, unfavorable alkali and etherification agent absorption, penetration, product substitution degree, poor uniformity and other problems , to achieve the effect of easy post-processing technology, good mud filtration, stable and reliable product performance

Active Publication Date: 2007-07-25

SHANGHAI EVEREST FINE CHEMICALS CO LTD

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Most foreign countries use isopropanol as a solvent and use a large solvent ratio to crush and etherify cellulose pulp. Although it has the advantages of high etherification efficiency, good product substitution and uniformity, there are also differences The price of propanol and other raw materials is relatively high, and the post-processing technology is relatively difficult;

[0004] In China, ethanol is usually used as the reaction medium, with a small solvent ratio, and produced by a kneader. Although it has the advantages of cheap ra

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

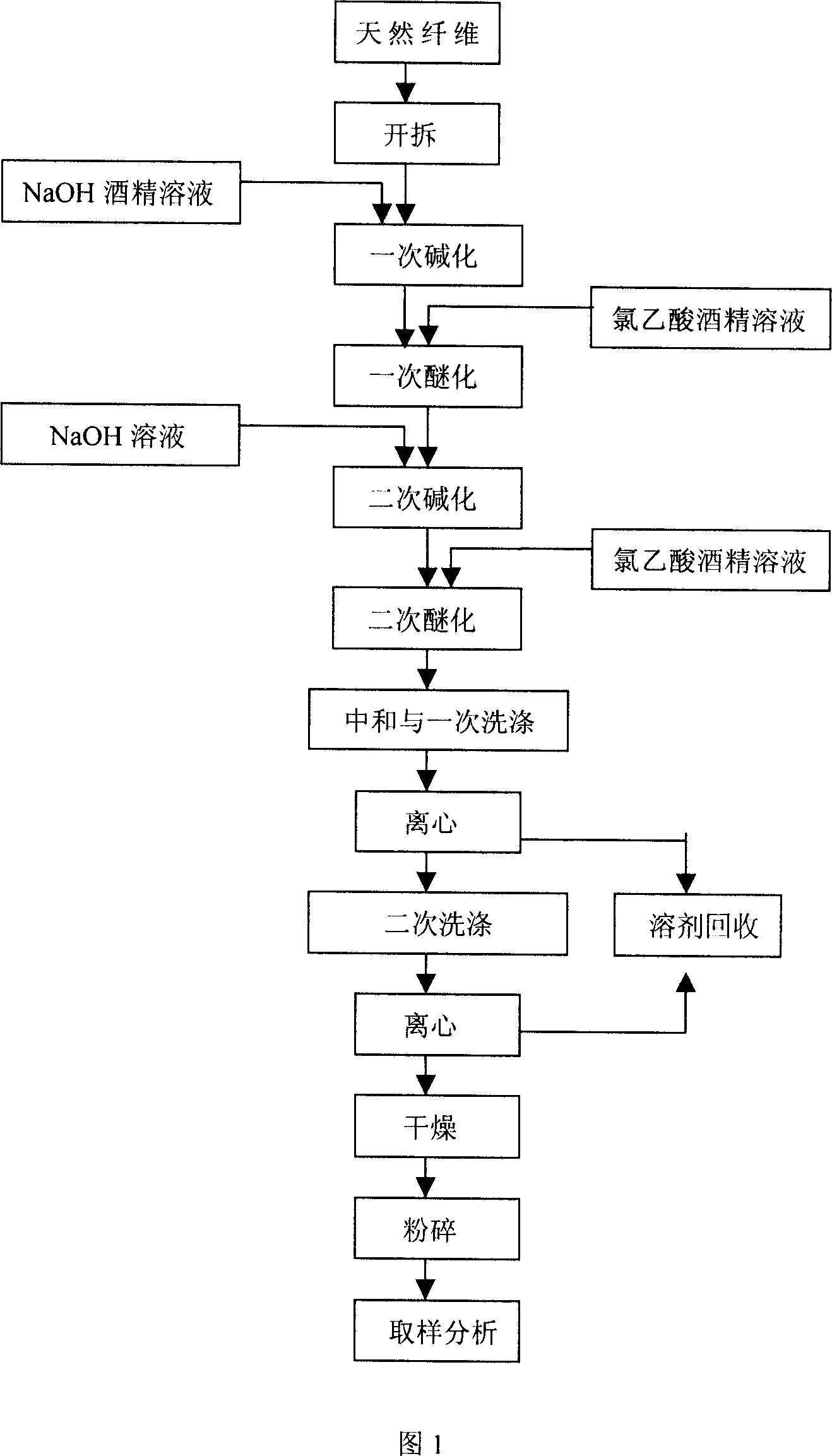

This invention discloses a process for producing highly substituted polyanionic cellulose. The method comprises: (1) adding natural cellulose into ethanol solution of NaOH in a kneading machine, alkalizing for 60 min, adding ethanol solution of chloroacetic acid, stirring, heating to 75-80 deg.C, and keeping the temperature for 60 min for etherisation; (2) cooling to below 35 deg.C, adding 50% NaOH solution, stirring uniformly, alkalizing for 60 min, adding ethanol solution of chloroacetic acid, stirring, heating to 75-80 deg.C, and keeping the temperature for 60 min for etherisation; (3) neutralizing, washing for twice, centrifuging to remove water and alcohol, drying, and pulverizing to obtain the product. The polyanionic cellulose has such advantages as high substitution degree, uniform substituent distribution, high resistance to heat, salt and corrosion, and low water loss, and can be used in the fields of oil well drilling, textile dyeing and food industry.

Description

technical field [0001] The invention belongs to the field of fine chemical production, and relates to a production process of polyanion cellulose with a high degree of substitution, in particular to a process for producing polyanion cellulose with a high degree of substitution by two times of alkalization and etherification. Background technique [0002] The existing multi-solvent method for the production of polyanionic cellulose at home and abroad, that is, using an inert organic solvent as the reaction medium, in a stirred tank or a kneader, the cellulose and the reaction reagent are fully and uniformly mixed in the medium to increase the reaction space between the reactants. The contact area can improve the transfer of reaction heat and improve the efficiency of etherification. in: [0003] Most foreign countries use isopropanol as a solvent and use a large solvent ratio to crush and etherify cellulose pulp. Although it has the advantages of high etherification efficien...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08B11/00C08B11/20

Inventor 丁长光袁和平丁长银李国荣张强聂熙金何婉缪秀英陈忠岐

Owner SHANGHAI EVEREST FINE CHEMICALS CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com