DC traction motor capable of speed measuring for narrow gage locomotive

A narrow-gauge locomotive and DC traction technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of inability to measure the speed value and the inability to install a speed sensor, etc., and achieve weight reduction, unique structure, and high control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

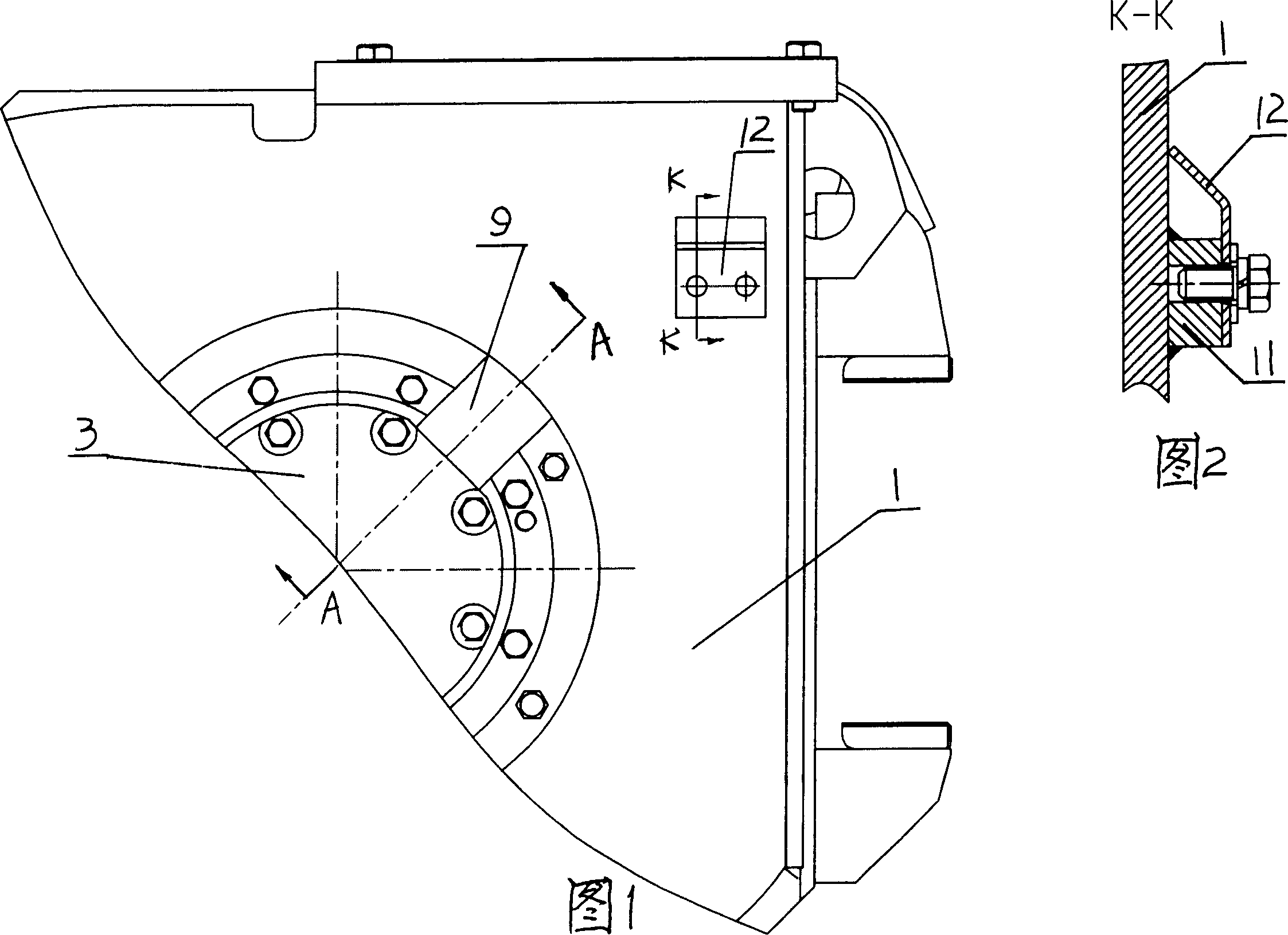

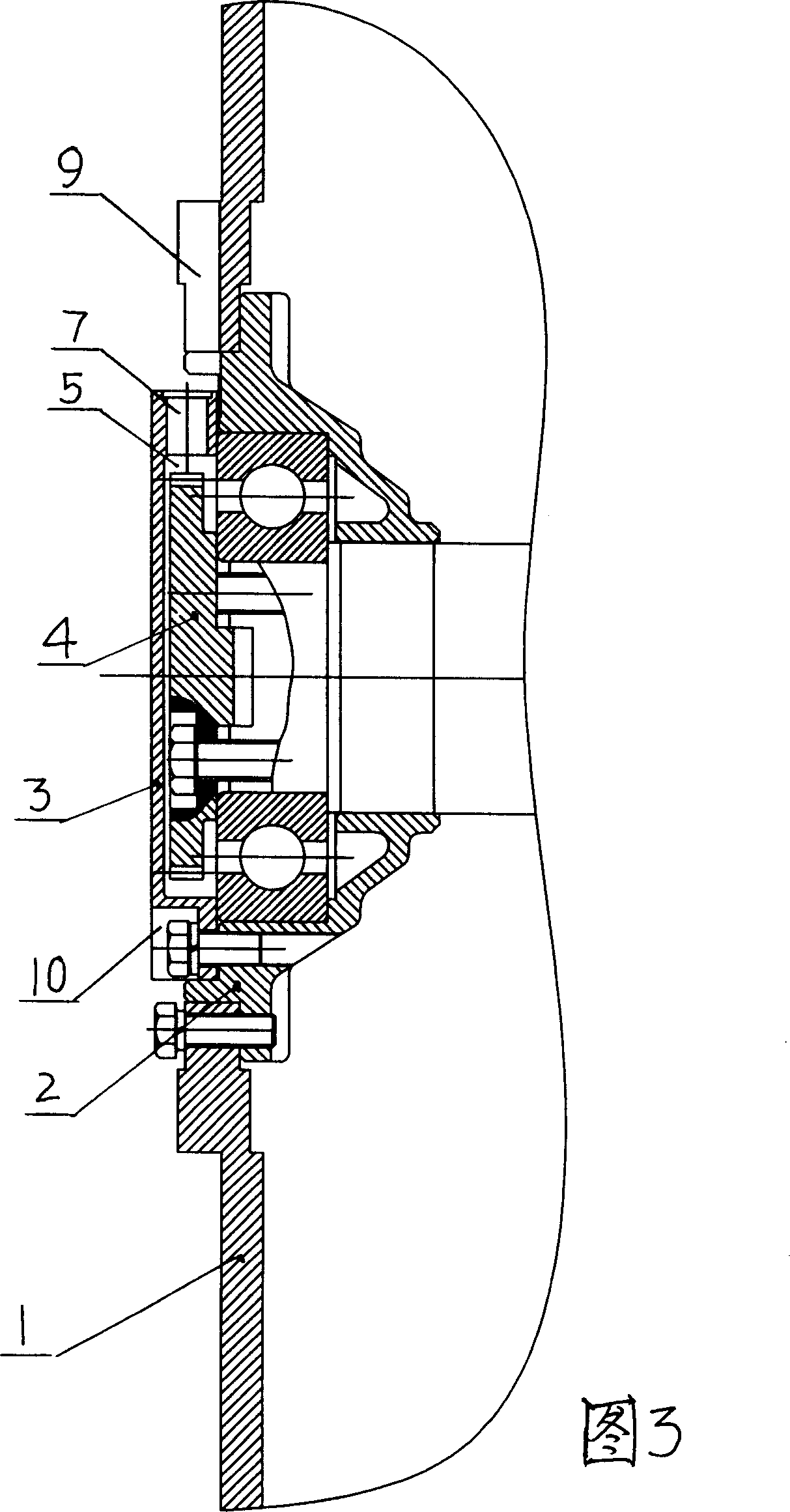

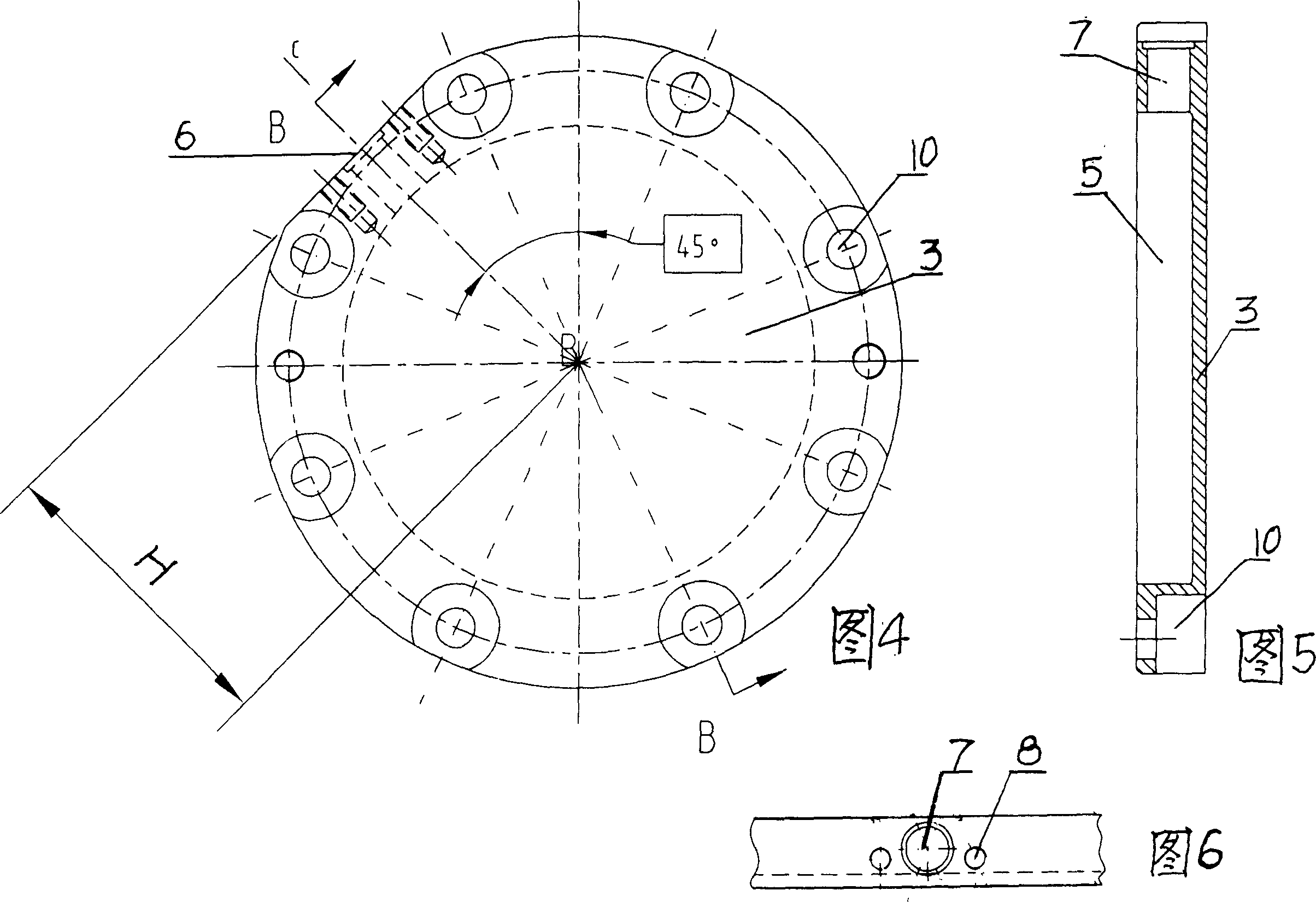

[0015] A DC traction motor for a narrow-gauge locomotive that can measure speed, including a base 1, an inner end cover 2 fixed to the base at the commutator end of the base, a bearing cover 3 fixed to the inner end cover, and a bearing cover between the bearing cover and the bearing The shaft head pressure plate 4; the bearing cover 3 is an integral disc structure (flat cylinder shape), and its inner end surface is opened (processed) with a counterbore 5 for the installation space of the speed measuring gear; a bearing cover is milled on the cylindrical surface Plane 6, on which there is a speed measuring hole 7 communicating with the counterbore on the inner side of the bearing cover and a screw hole 8 for fixing the speed sensor; a flange at the connection between the inner end cover and the machine base is milled with a bearing The groove 9 opposite to the milled plane on the cover, the speed sensor is placed in the groove, the speed sensor is aligned with the speed hole on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com