Fixed-frequency AM electric vortex displacement sensor of linear automatic compensation

A displacement sensor and automatic compensation technology, which is applied in the direction of transmission of sensing components, instruments, circuits, etc. using electric/magnetic devices to achieve the effect of highlighting temperature compensation characteristics and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

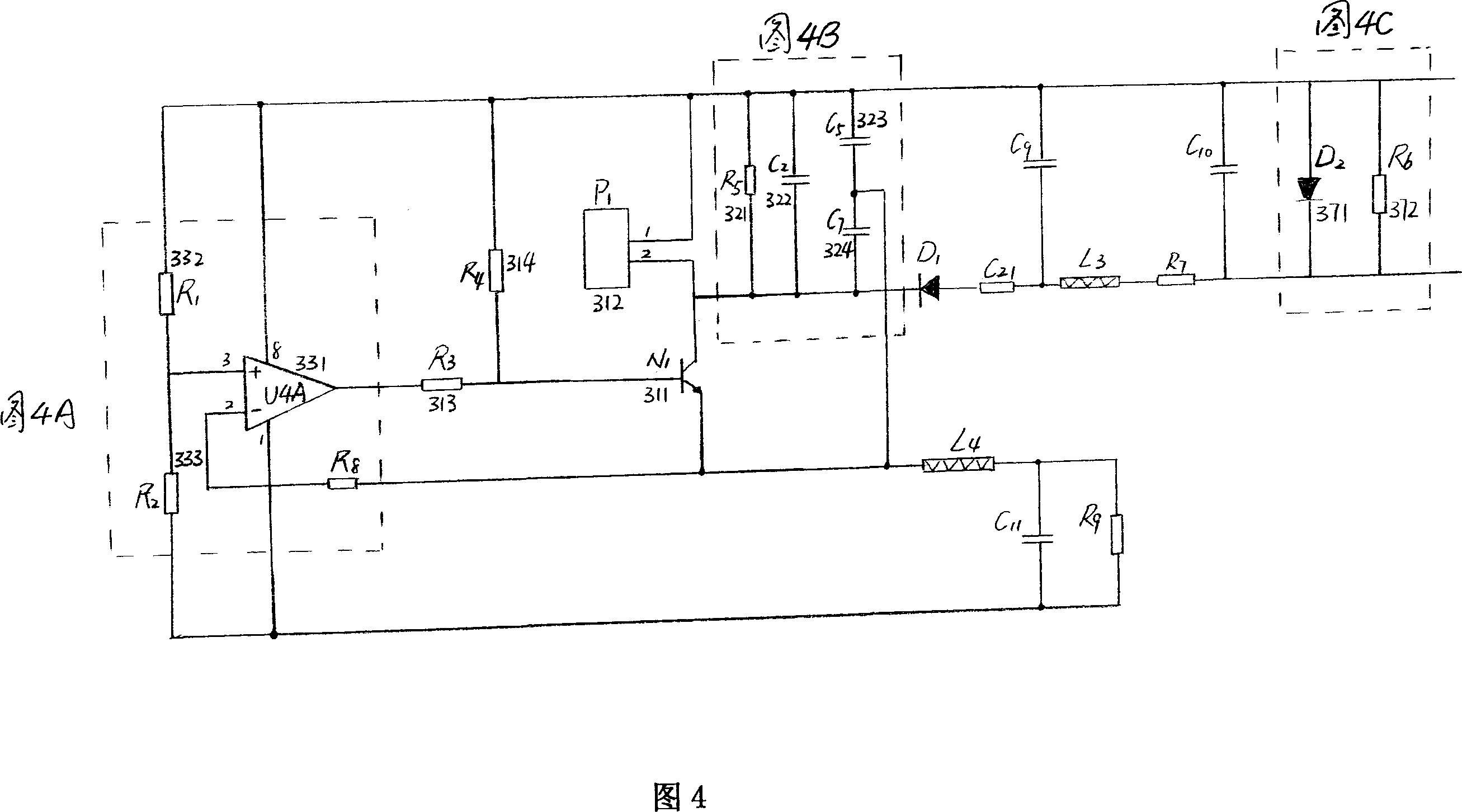

[0054] Please refer to the accompanying drawings for a further description of the present invention.

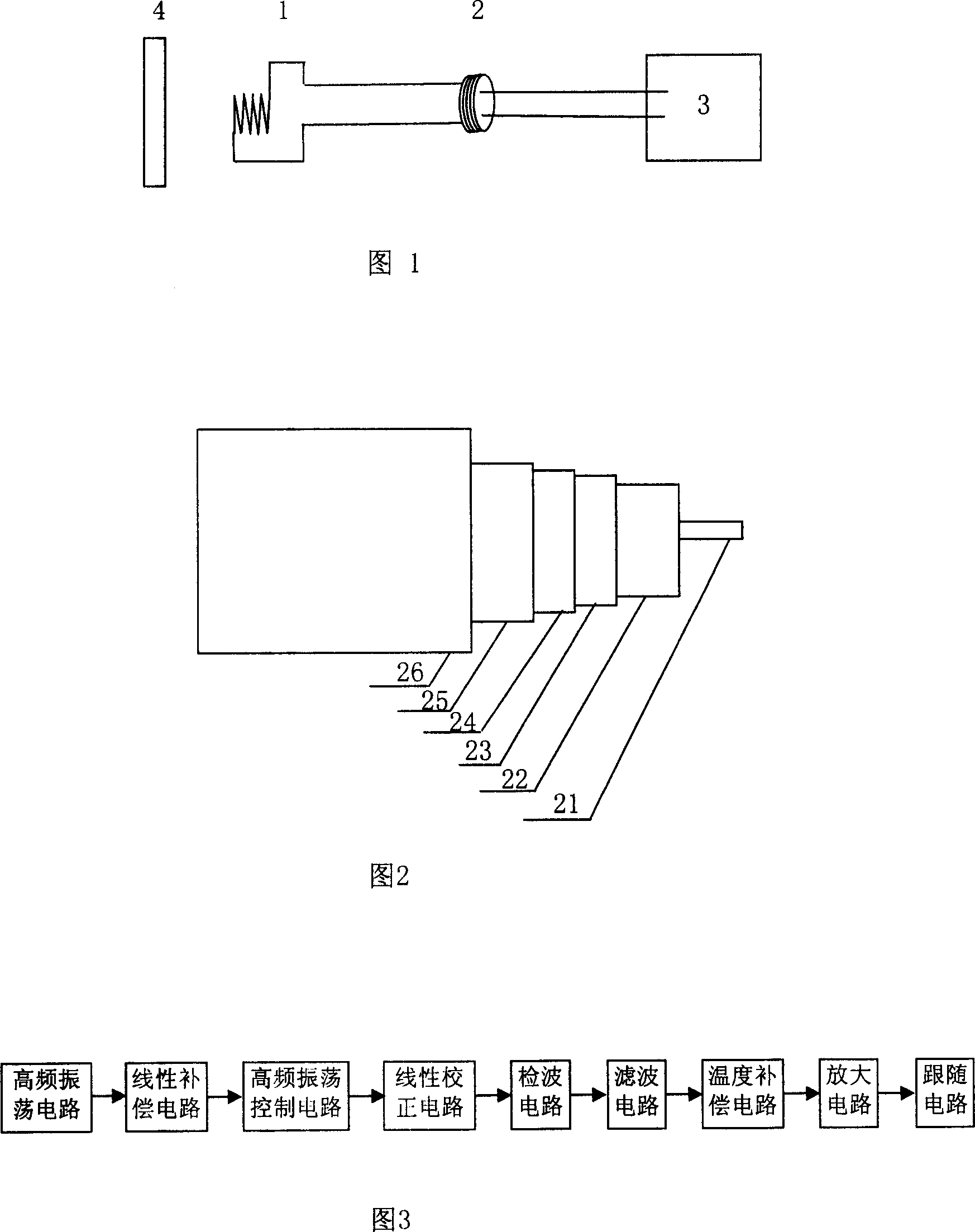

[0055] As shown in Fig. 1, the present invention provides a linear automatic compensation fixed frequency amplitude modulation eddy current displacement sensor. Including eddy current probe 1, coaxial cable 2 and preamplifier circuit 3, the probe 1 is connected to the coaxial cable 2, the palladium-silver alloy coil in the probe 1 generates high-frequency current, and the temperature compensation circuit is used to compensate the probe 1 and the coaxial Temperature drift error of cable 2.

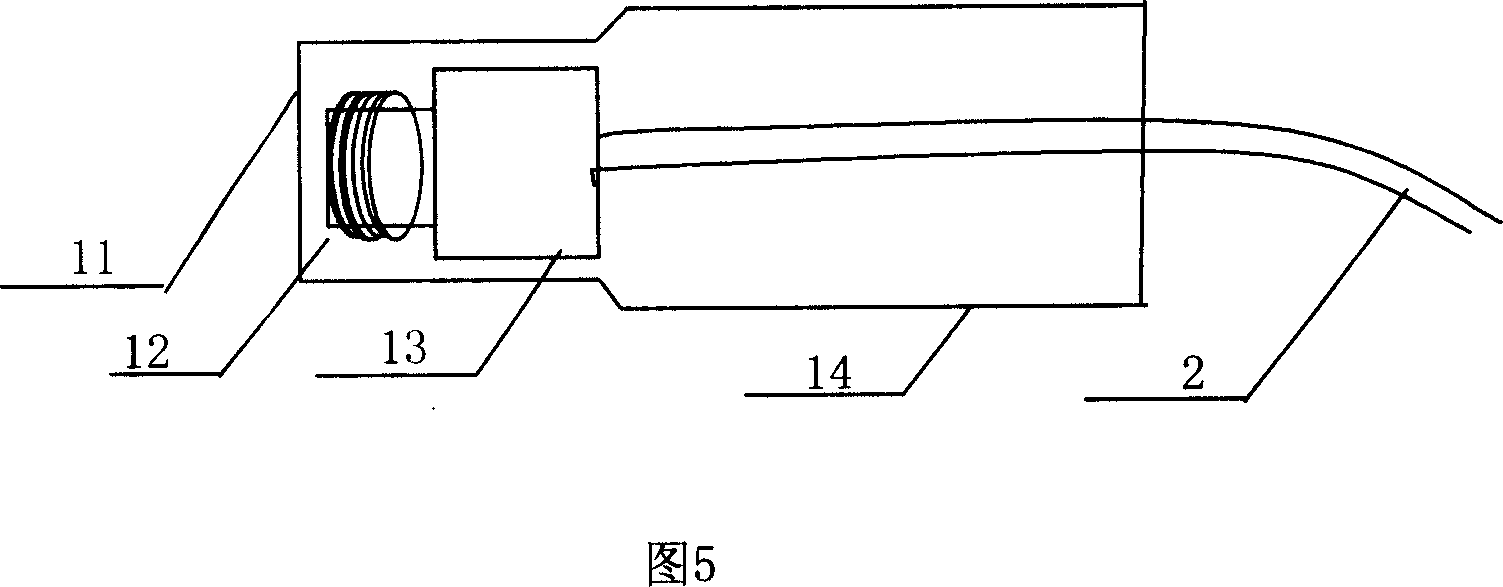

[0056] As shown in FIG. 5 , the eddy current probe 1 is composed of a probe coil 12 , a skeleton body 13 , a protective cover 11 , a stainless steel shell 14 and a coaxial cable 2 . The probe coil 12 is made of palladium-silver alloy wire, and the formula ratio of the palladium-silver alloy wire is 75-85% of palladium element content and 15-25% of silver element content. Palladium and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com