Rotary cup spinning device provided with drivable rotary cup

A technology of rotor spinning and rotor spinning, which is applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc., and can solve the problem of speed increase and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

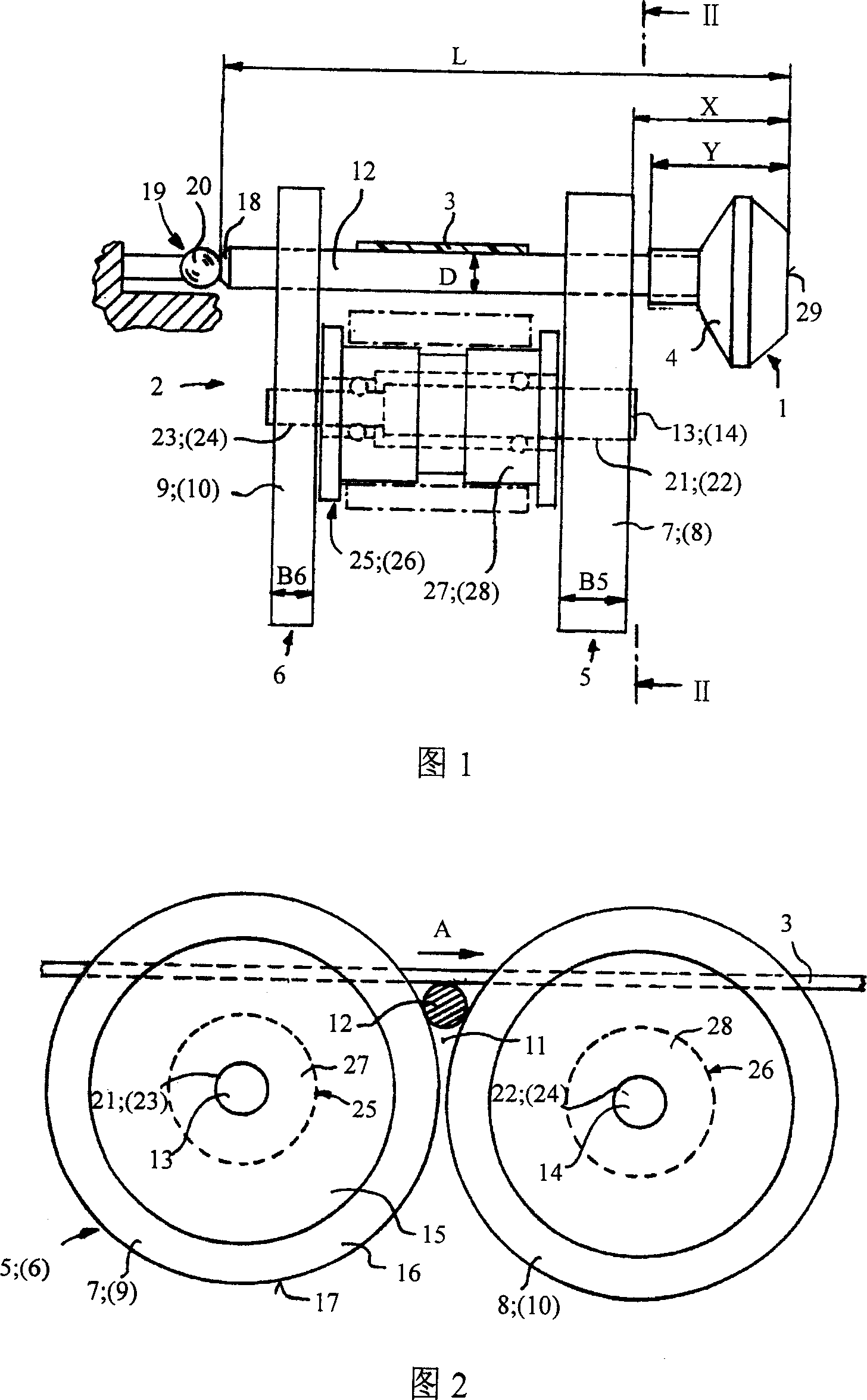

[0016] The rotor spinning device shown only partially in FIGS. 1 and 2 basically shows a rotor spinning device 1 , which is mounted in a support disk bearing 2 and can be driven by a tangential drive belt 3 . The rotor spinning 1 has a rotor disc 4 in which the actual yarn formation process takes place. Devices for adding individual yarns and for doffing the spun yarn from the rotor disc 4 are added to the rotor disc 4 in a manner not shown but known per se.

[0017] The support disc bearing 2 comprises two support disc pairs 5 and 6 with two support discs 7 and 8 and 9 and 10 each. The pair of support disks 5 and 6 forms a wedge-shaped gap 11 in which a rotor shaft 12 of a rotor spinning 1 fastened to the twist ring disk 4 is radially supported. The supporting disks 7 and 9 and 8 and 10 , which are respectively located on the side next to the rotor shaft 12 , are arranged on a common shaft 13 or 14 .

[0018] The structures of the support discs 7, 8, 9 and 10 are basically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com