Automatic charging method of robot and its automatic charging device

A technology of automatic charging and robotics, applied to instruments, manipulators, non-electrical signal transmission systems, etc., can solve problems such as low work efficiency and poor adaptability, and achieve high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

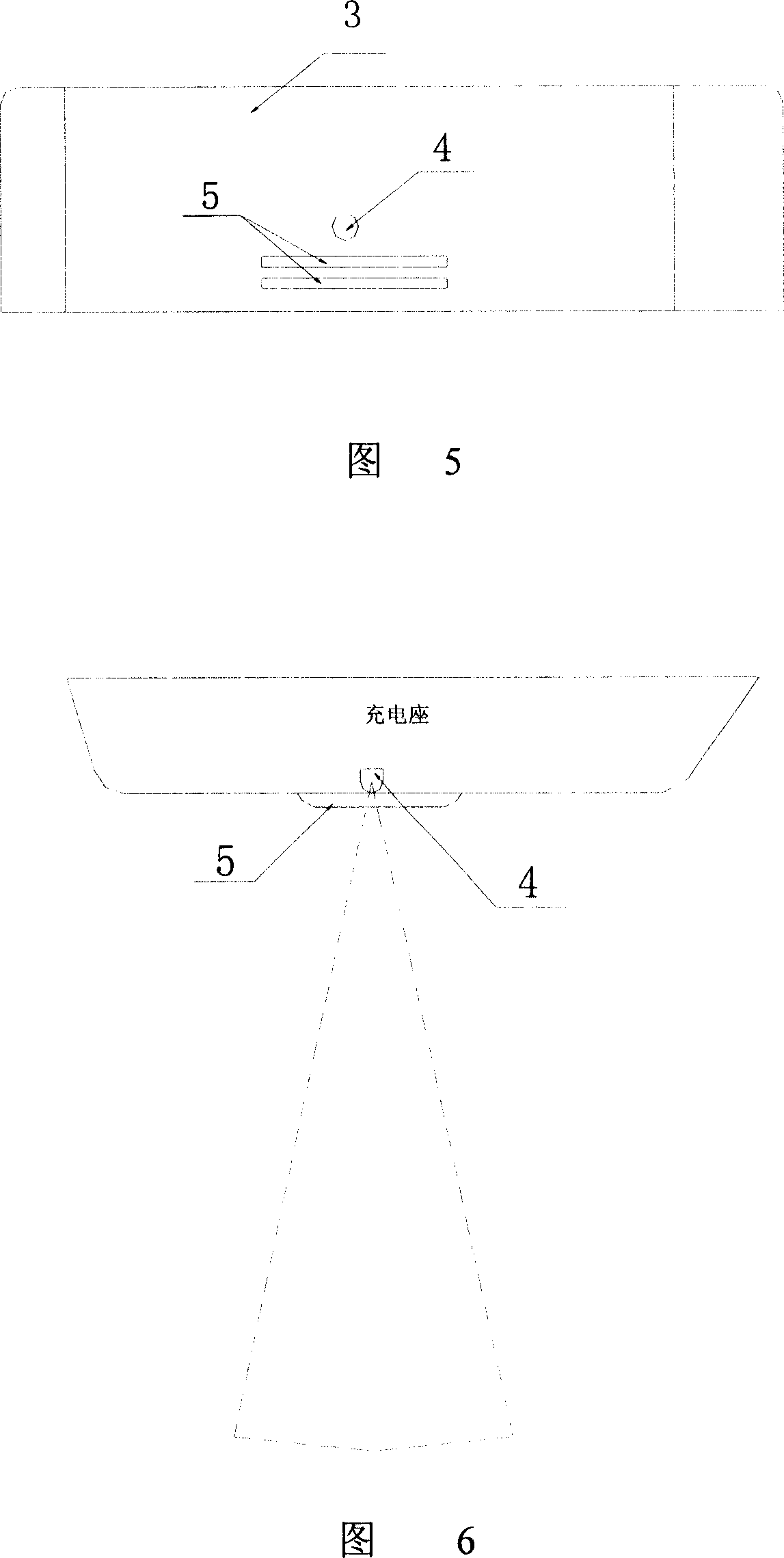

[0058] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, Fig. 8, Fig. 9, Fig. 10, Fig. 11, a method for automatic charging of a robot, the described method has the following steps:

[0059] (1), when the robot needs to supplement the power supply, open the infrared information receiving device 1 located at the front of the robot. The infrared information receiving device includes a plurality of infrared receiving tubes distributed on the front of the robot body. The receiving device searches for the infrared charging guidance signal on the charging stand 3;

[0060] (2), after the infrared information receiving device 1 finds the guiding signal, determine the infrared receiving tube that receives the guiding signal, and calculate the distance and angle of the charging base 3 relative to the robot according to the infrared receiving tube;

[0061] (3), determine whether the orientation of the charging stand 3 is directly in front of the robot,

[0062] (3.1)...

Embodiment 2

[0074] With reference to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, Fig. 8, Fig. 9, Fig. 10, Fig. 11, the front portion of the robot of this embodiment is also provided with a trigger signal transmitter 6, The charging stand is also provided with an excitation module 7 for starting the guiding signal emission source according to the trigger signal, and a closing module 9 for closing the emission source after the docking is completed, and the (1) includes:

[0075] (1.1), when the robot needs to supplement the power supply, open the infrared information receiving device 1, the trigger signal transmitter 6 positioned at the front of the robot, and the trigger signal transmitter 6 sends the trigger information;

[0076] (1.2), the excitation module 7 on the charging stand receives the trigger signal, starts the pilot signal emission source 4, and emits the pilot signal;

[0077] (1.3), the robot walks randomly, and the infrared information receiving device 1 searches...

Embodiment 3

[0083] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, Fig. 12, Fig. 13, Fig. 14, the method of this embodiment, the guide signal emission source of the charging stand according to different The infrared frequency includes the left emission source, the middle emission source, and the right emission source, and the (3.1) mentioned includes:

[0084] (3.1.1) If the infrared information receiving device of the robot receives the guidance signal from the left emission source, control the robot to move to the right until the infrared information receiving device receives the guidance signal from the middle emission source, and adjust according to the angle of the charging stand until The robot is facing the charging stand;

[0085] (3.1.2) If the infrared information receiving device of the robot receives the guidance signal from the right emission source, control the robot to move to the left until the infrared information receiving device receives the guidanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com