Cyclone separation device of dust collector

A technology of a cyclone separation device and a vacuum cleaner, which is applied to suction filters and other directions, can solve the problems of large diameter and inability to use a cyclone separation device, etc., and achieve the effect of height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

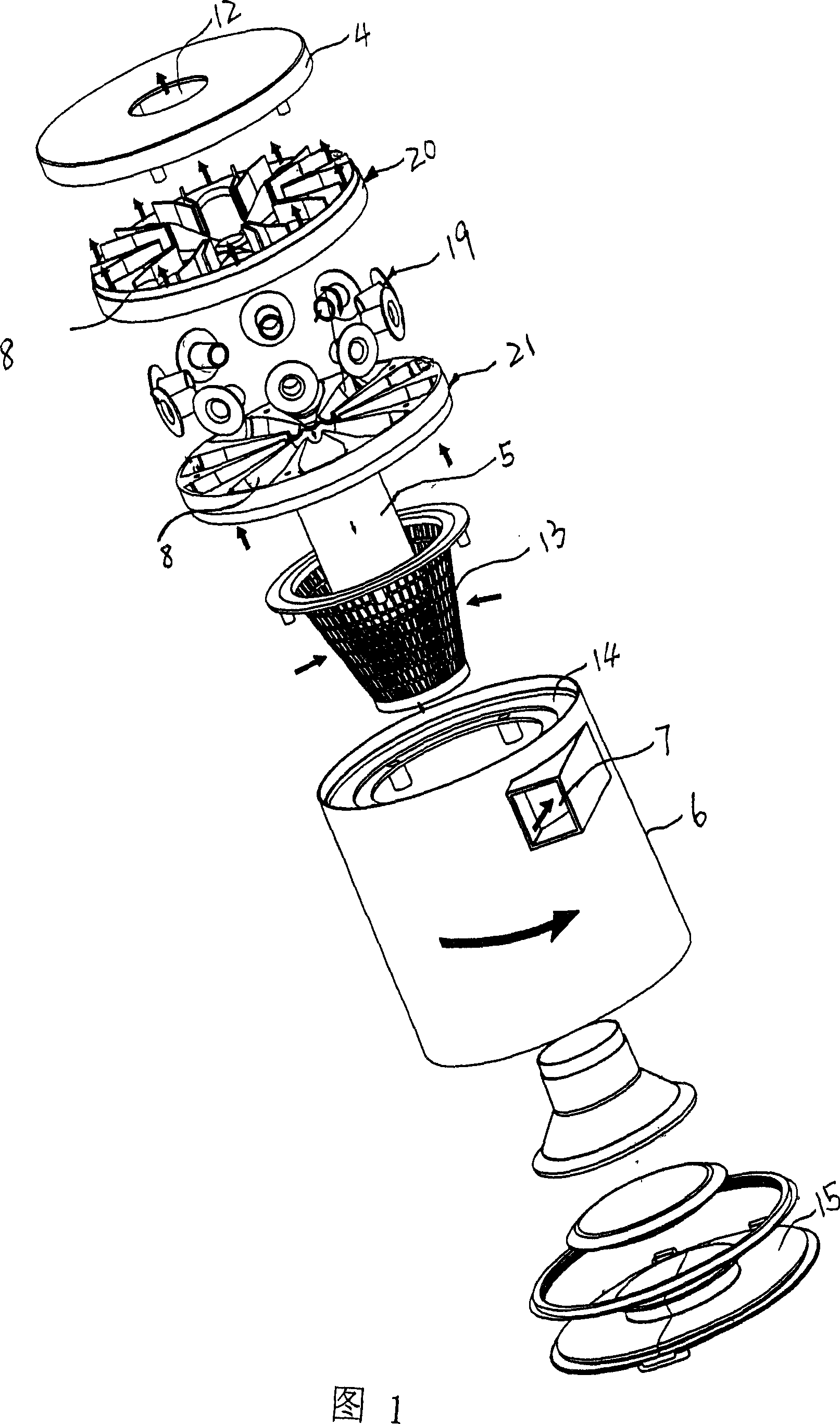

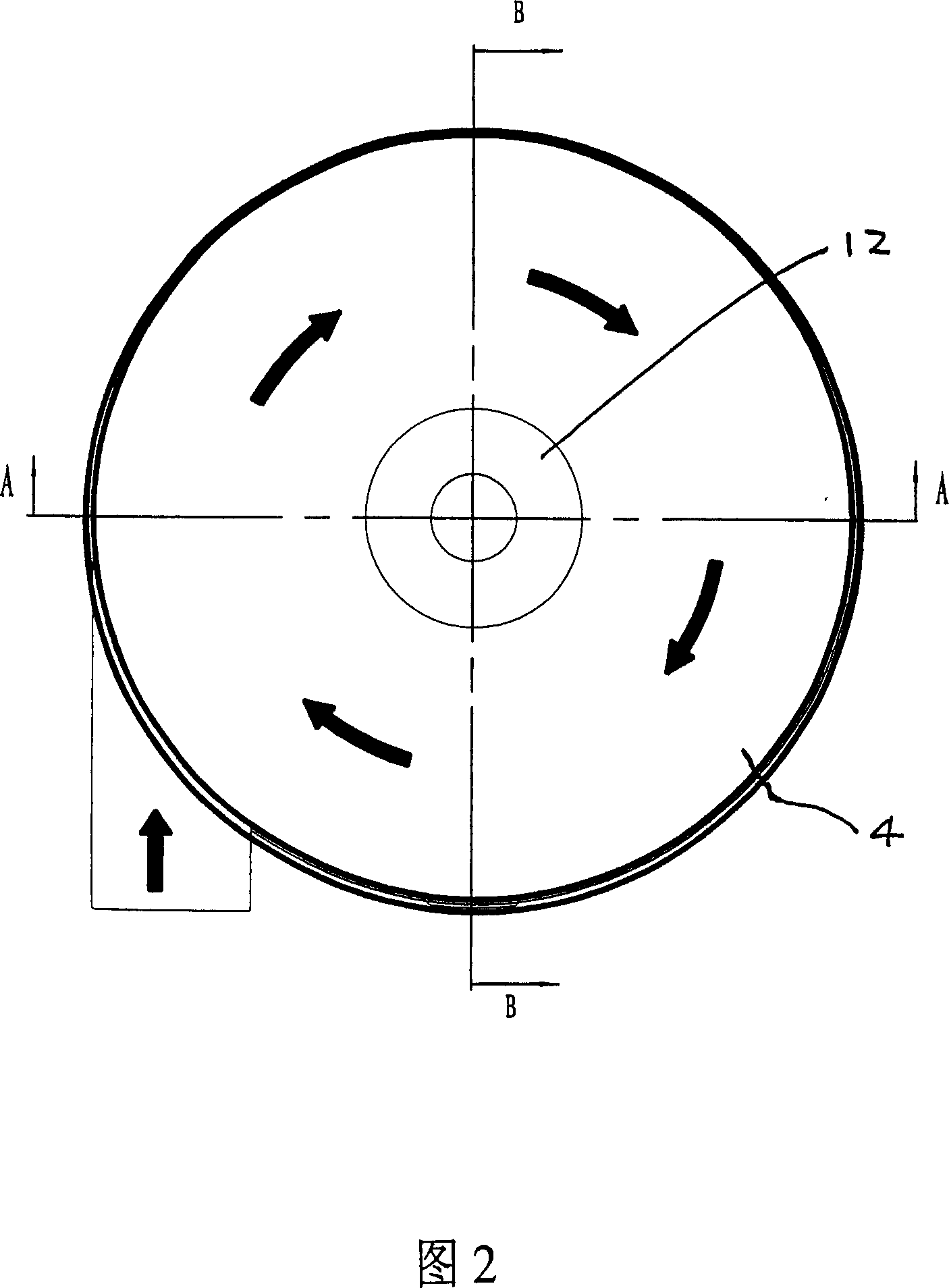

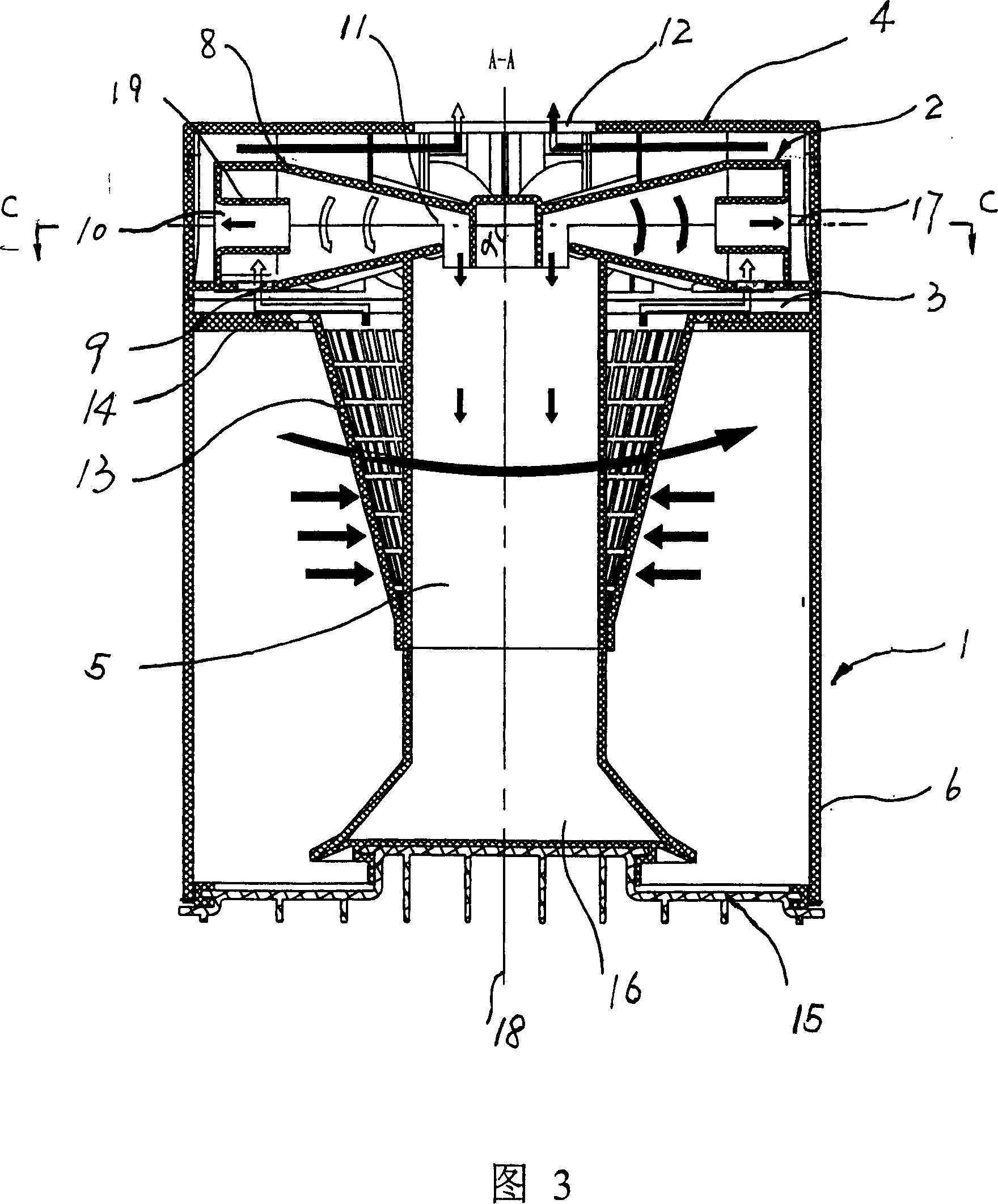

[0028] As shown in Figures 1 to 5, the cyclone separation device of the vacuum cleaner includes an upstream cyclone separation device 1 and a downstream cyclone separation device 2. The upstream cyclone separation device 1 and the downstream cyclone separation device 2 are connected through a gas channel 3, so The upstream cyclone separation device 1 has a first cyclone barrel 6, and the downstream cyclone separation device 2 includes 10 second cyclone barrels 8 in which a plurality of second cyclone barrels 8'are arranged side by side. Each of the downstream cyclone separation devices 2 It is arranged lying down above the upstream cyclone separator 1. Said lying is full lying, that is, the included angle α between the axis 17 of the second cyclone barrel 8 and the axis 18 of the first cyclone barrel 6 is 75 degrees to 125 degrees, which is basically full Lying down.

[0029] In this embodiment, the included angle a between the axis 17 of the second cyclone barrel 8 and the axis 1...

Embodiment 2

[0036] As shown in Figures 6 and 7, the cyclone separation device of the vacuum cleaner includes an upstream cyclone separation device 1'and a downstream cyclone separation device 2'. The upstream cyclone separation device 1'and the downstream cyclone separation device 2'pass between The gas passage 3'is in communication, the upstream cyclone separation device 1'has a first cyclone barrel 6', the downstream cyclone separation device 2'includes 8 second cyclone barrels 8', and the respective downstream cyclone separation devices 2'lie It is installed above the upstream cyclone separation device 1'. The lying is half-lying, that is, the angle α between the axis 17' of the second cyclone barrel 8'and the axis 18' of the first cyclone barrel 6'is 15 degrees to 165 degrees Is half-lying.

[0037]In this embodiment, the included angle a between the axis 17' of the second cyclone barrel 8'and the axis 18 of the first cyclone barrel 6'is 135 degrees, and the first cyclone barrel 6' A firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com