Point adhering cloth for filling down

A technology of point bonding and flannelette, which is applied in the field of woven fabrics, can solve the problems of less down, troublesome filling, and affecting comfort, and achieve the effect of improving the bulkiness of down, making the product soft and comfortable, and improving the quality of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

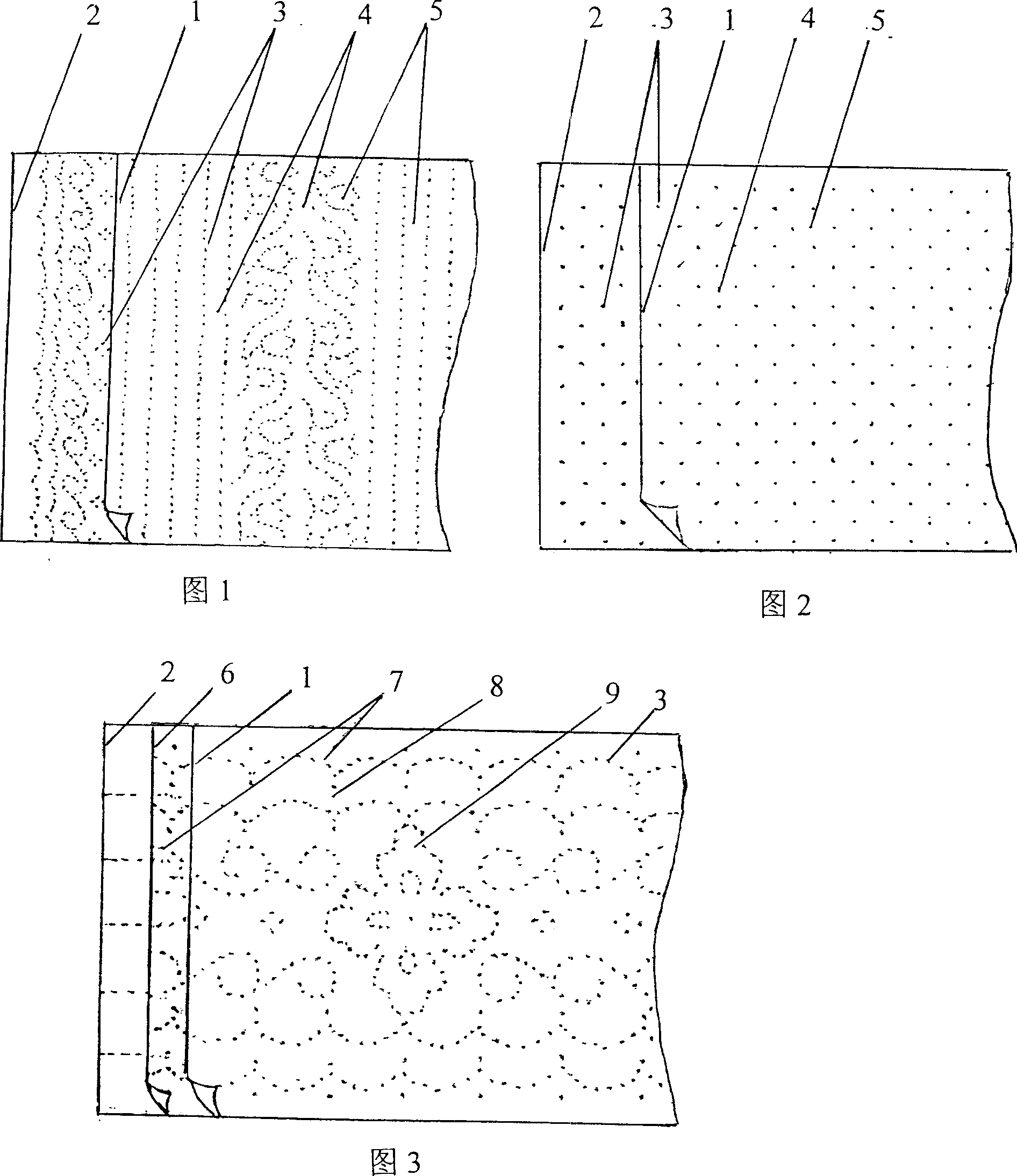

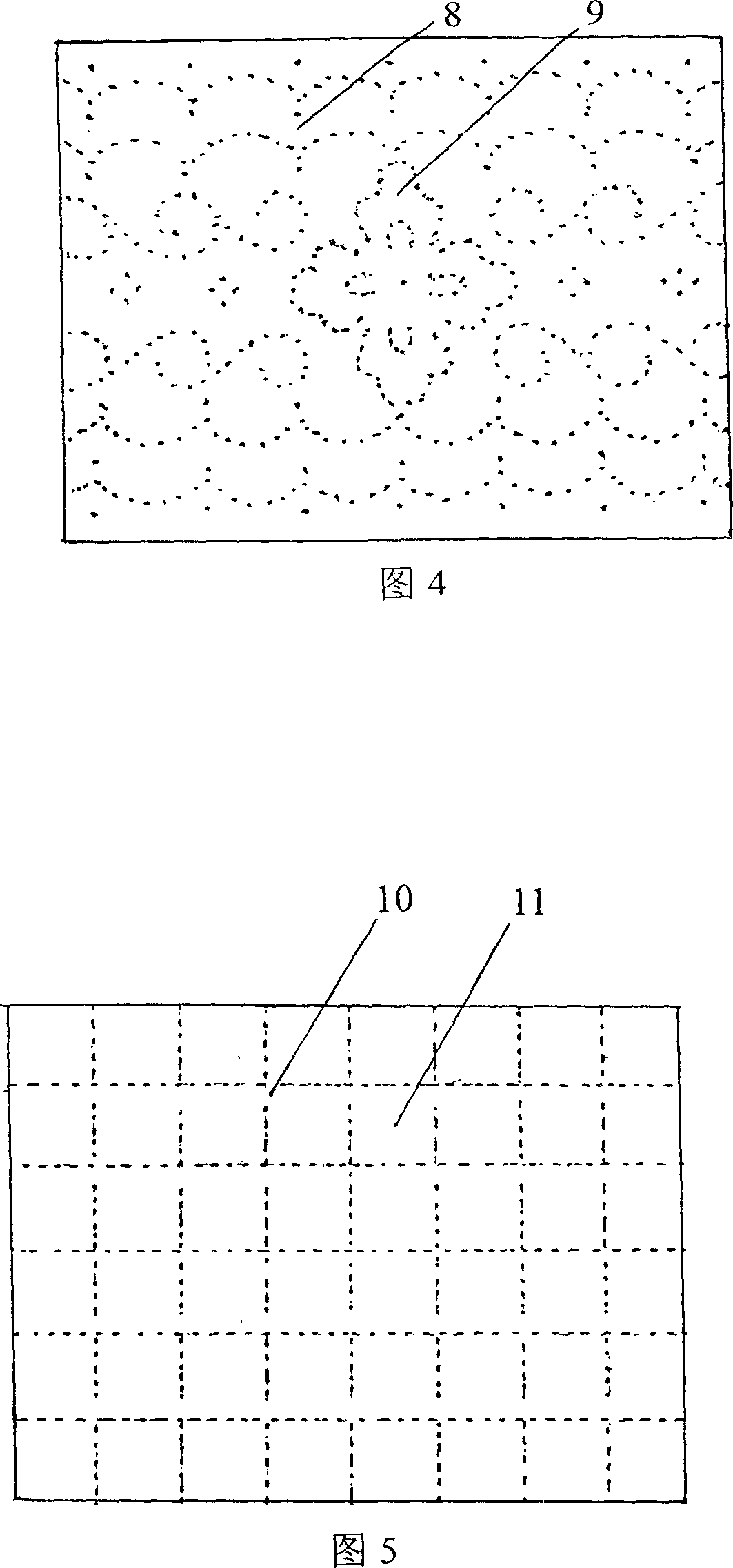

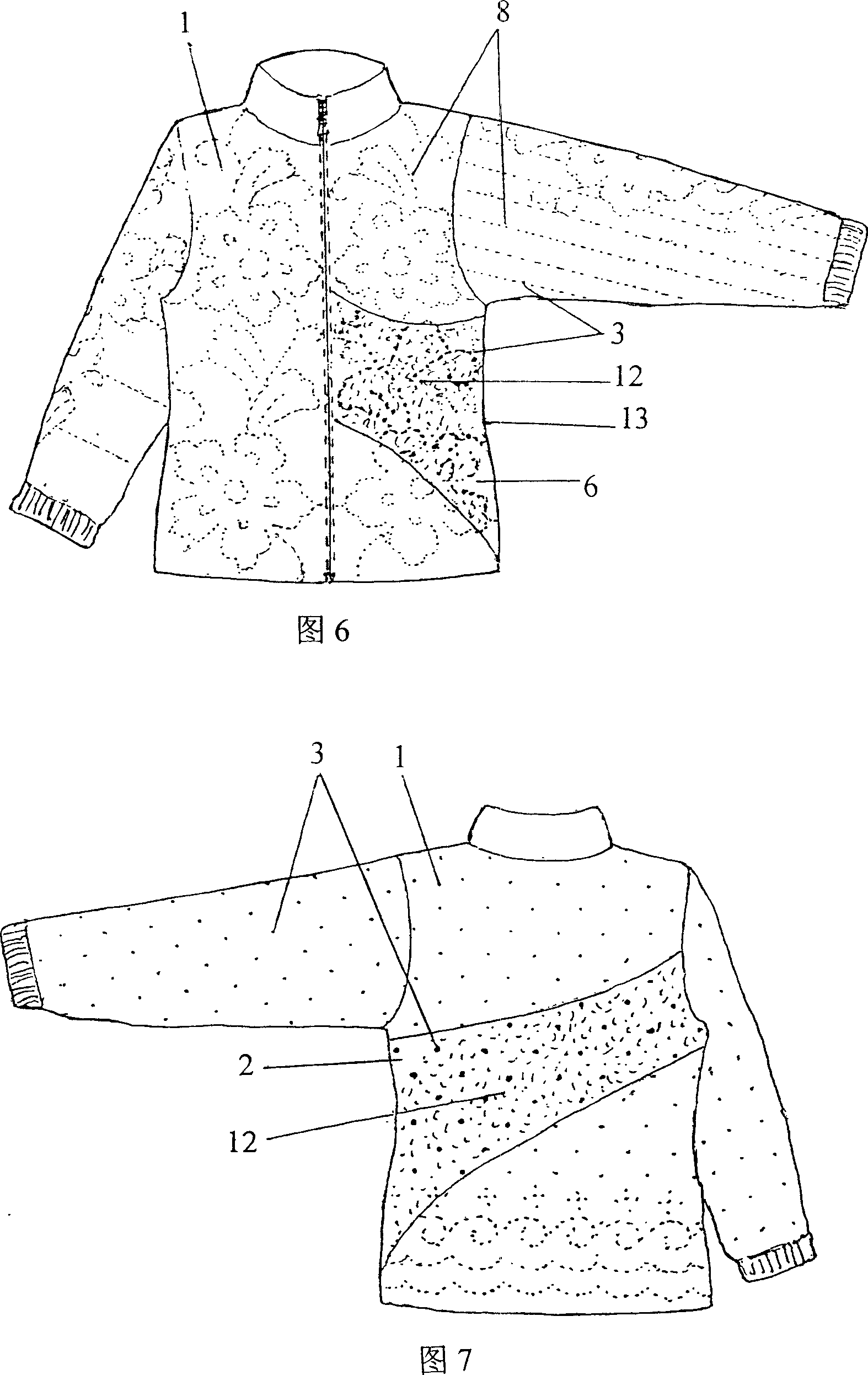

[0017] As shown in Figure 1, it includes face cloth 1 and inner cloth 2; face cloth 1 and inner cloth 2 are bonded alternately with sticky points 3 arranged in arcs, straight lines and patterns, and each sticky point 3 is arranged in lines to form a full The down channel 4 and the down filling space 5, the distance between two adjacent sticking points 3 is a small channel for down slapping.

[0018] As shown in Figure 2, it includes face cloth 1 and lining cloth 2; face cloth 1 and lining cloth 2 are formed by arranging sticky points 3 in a square or diamond shape, and the bonding points between face cloth 1 and lining cloth 2 are Down-filling channel 4 and down-filling space 5 are formed between them, down-filling space 4 is formed around the sticking point 3, and the distance between two adjacent sticking points 3 is a small down slapping channel.

[0019] As shown in Figure 3, it includes face cloth 1, middle layer cloth 6 and inner cloth 2; middle layer cloth 6 and face cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com