Large-scale engine

A kind of engine, large-scale technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of increasing cost and location requirements, high speed, etc., achieve high stability and anti-vibration rigidity, compact structure, reliable axial The effect of suction flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

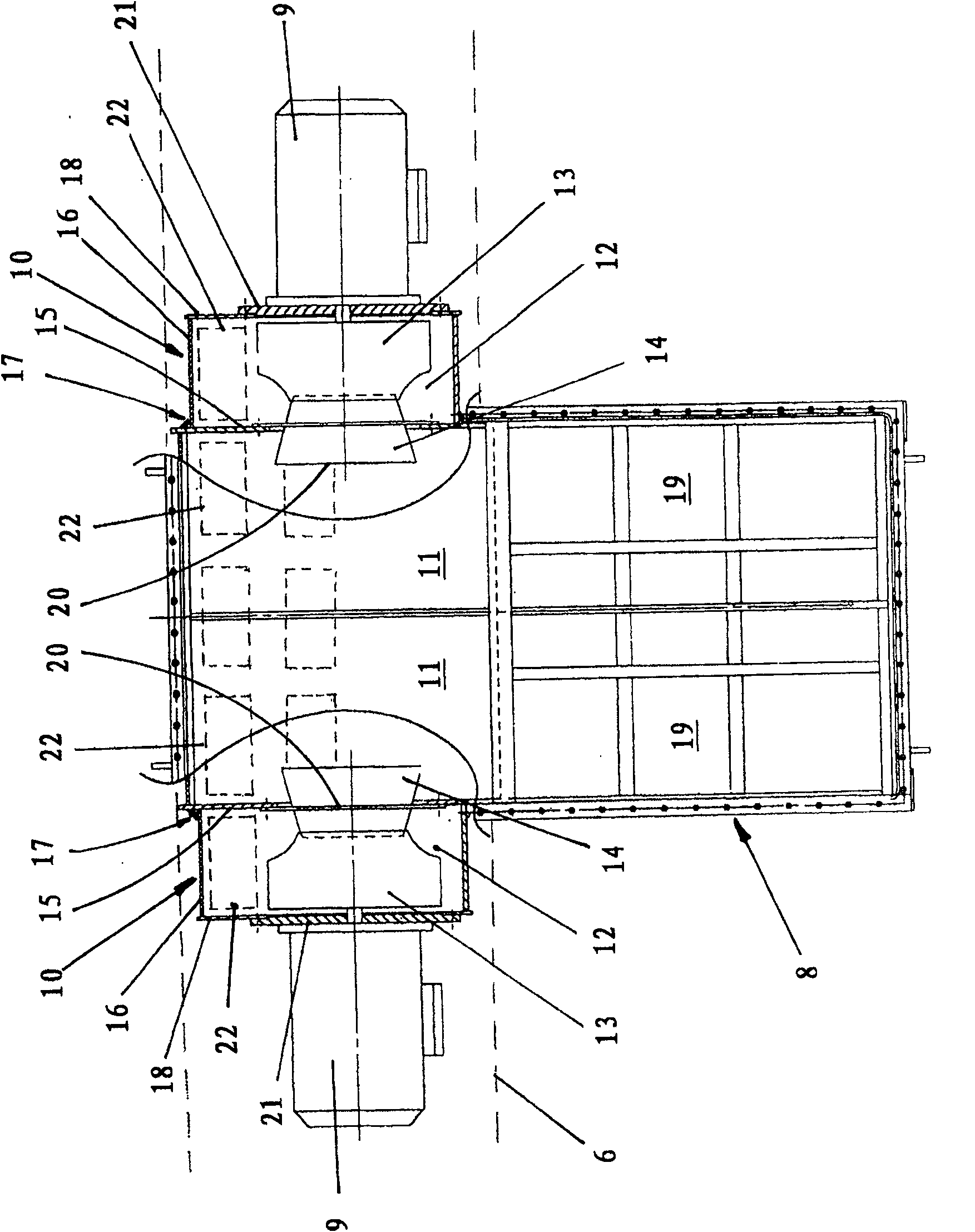

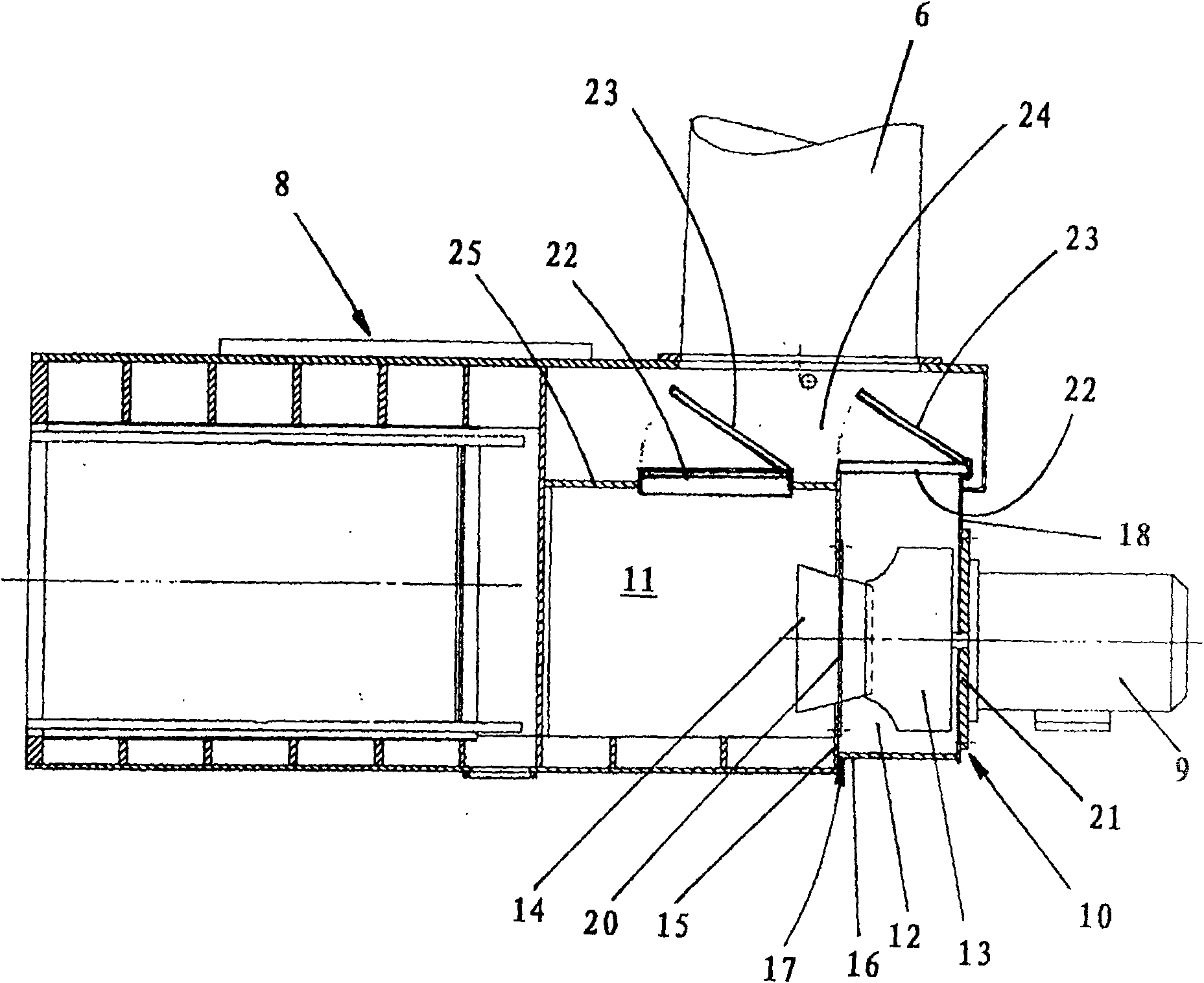

[0020] figure 1 Indicates a large engine of an invention. Here it can be a two-stroke large diesel engine. The basic structure and operating principle of such engines are well known, and they can be used, for example, as ship drives or generator drives.

[0021] figure 1 The engine shown in is equipped with an exhaust gas turbocharger 1, whose turbine 2 works with the exhaust gases produced during combustion in the engine cylinders, whose compressor 3 compresses the air sucked in via the air filter 4, which is fed as charge air cylinder. The turbine 2 is connected via a supply line to an exhaust gas collecting line 5 through the respective cylinder, to which the exhaust gas outlet of the respective cylinder is connected. In the illustrated embodiment, the exhaust gas collecting duct extends over all cylinders of the engine which are arranged side by side. The air compressed by the compressor 3 is fed into a charge air container 6 to which at least one set of associated cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com