Engine

An engine and transmission technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as restricting the miniaturization of engines and poor workability, and achieve improved assembly and maintenance, as well as improved assembly and maintenance. , The effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

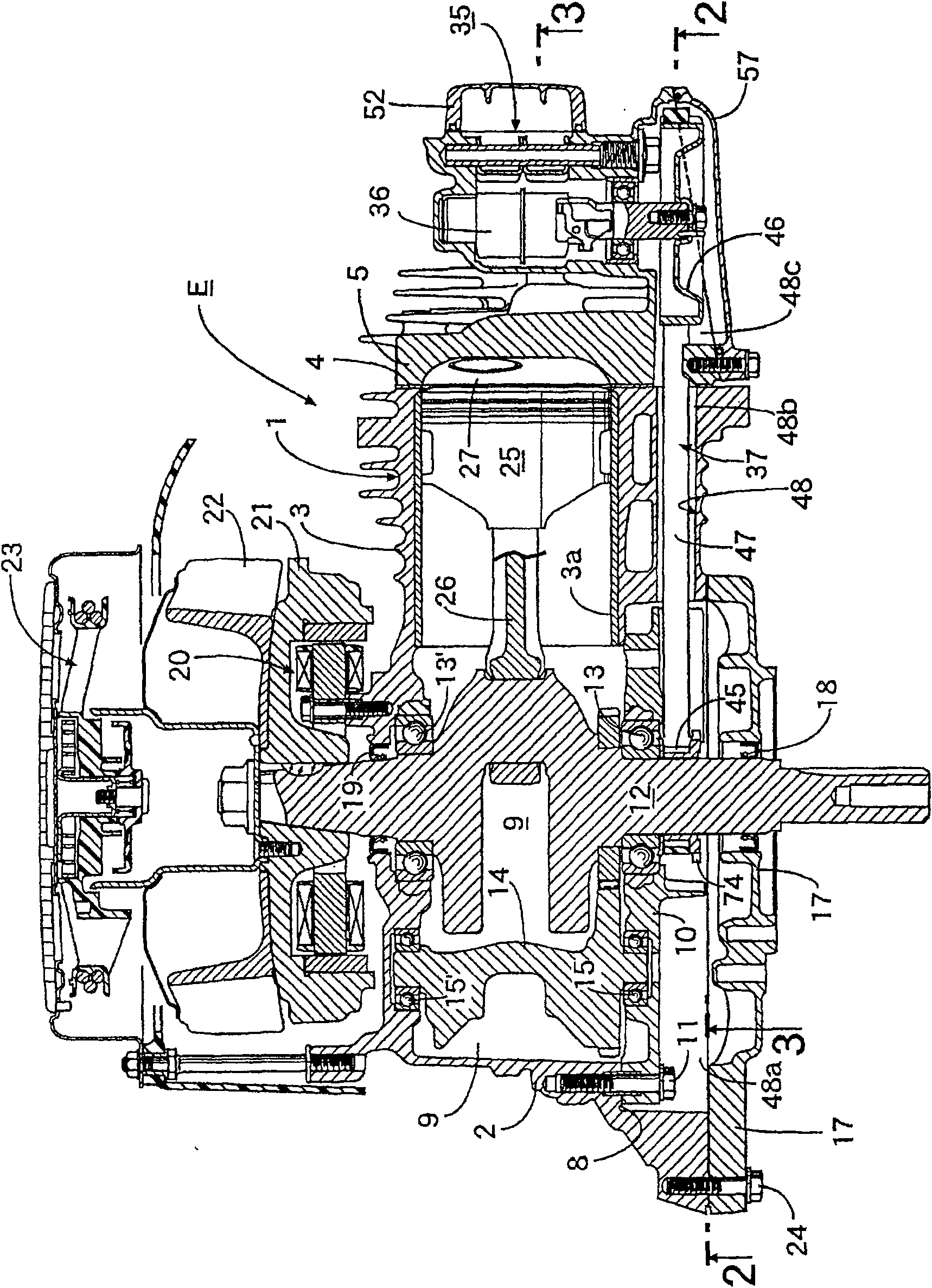

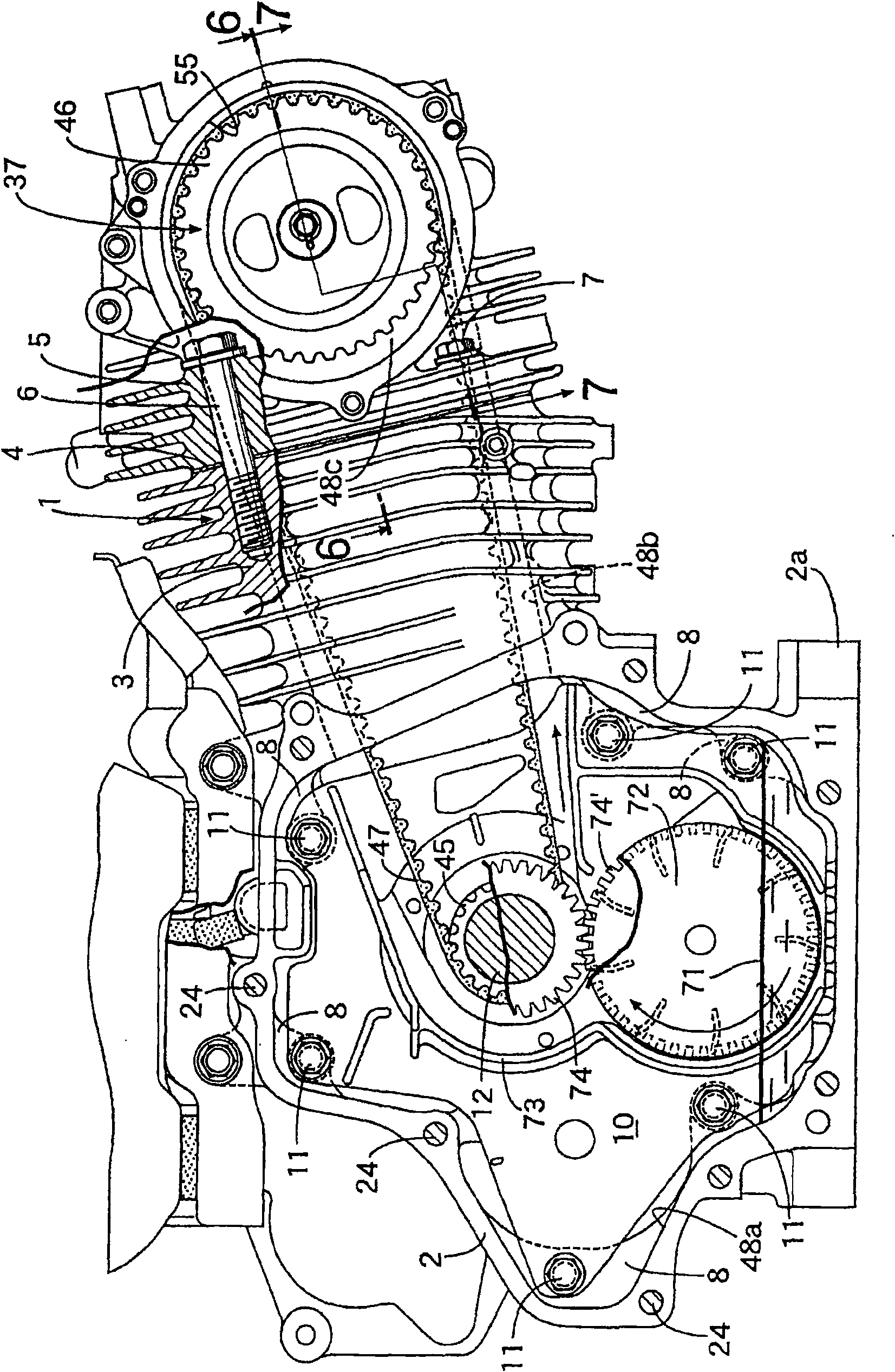

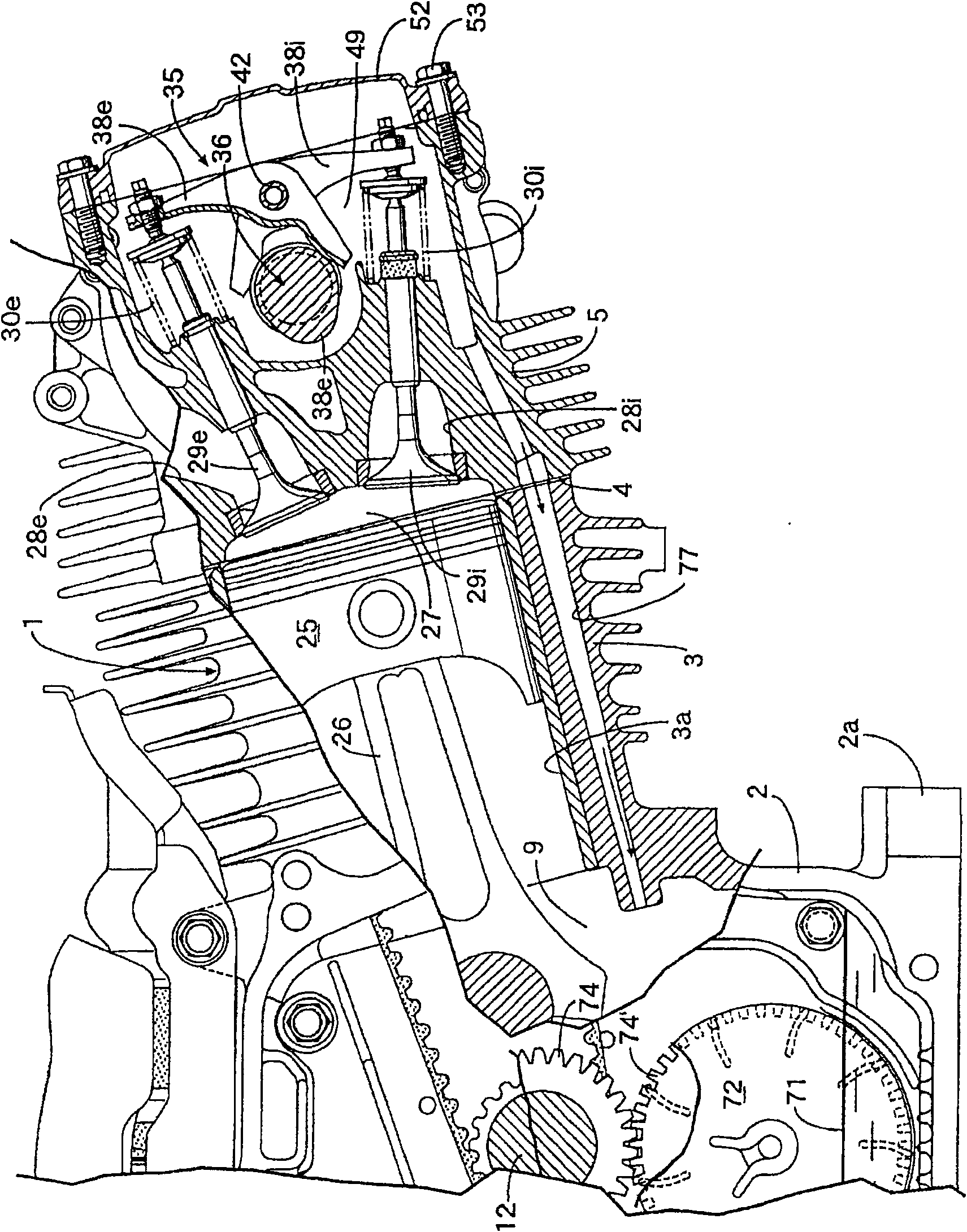

[0039] First, in Figure 1 ~ Figure 4 Among them, the constituent elements of the engine main body 1 of the general-purpose four-stroke engine E include: a crankcase 2 having a mounting seat 2a at the bottom; a cylinder block 3 integrally connected with the crankcase 2 and having an upwardly inclined cylinder bore 3a; The cylinder head 5 to which the gasket 4 is joined to the upper end of the cylinder block 3 is fastened using four main fastening bolts 6 arranged at four positions around the cylinder bore 3 a. 6... and two auxiliary connecting bolts 7, 7 described later.

[0040] The crankcase 2 has one side open, and a plurality of stepped portions 8, 8... are integrally formed on the inner peripheral wall slightly inward from the open surface, facing the open surface side and juxtaposed in the circumferential direction. The bearing bracket 10 is fixed on the parts 8, 8... by a plurality of bolts 11, 11.... Both ends of the crankshaft 12 in a horizontal posture are supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com