Stay-supported photoelectric two-dimensional displacement sensor

A two-dimensional displacement and angular displacement sensing technology, which is applied in the field of displacement sensors, can solve the problems of inconvenient measurement of high-precision and large-range displacement, high requirements for sensor installation, and large space occupation, and achieve light weight, low environmental requirements, and improved The effect of the ability to automatically control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

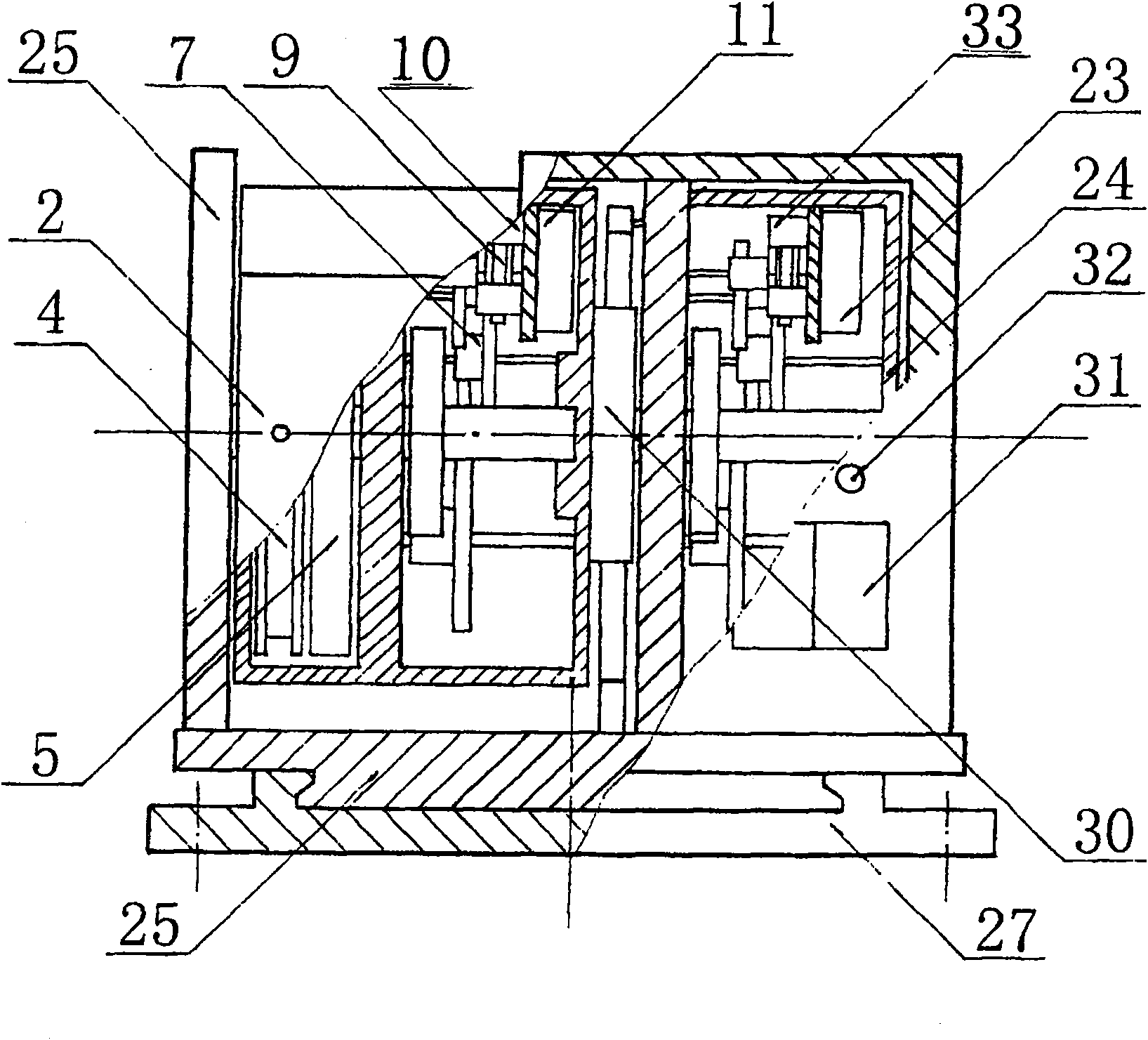

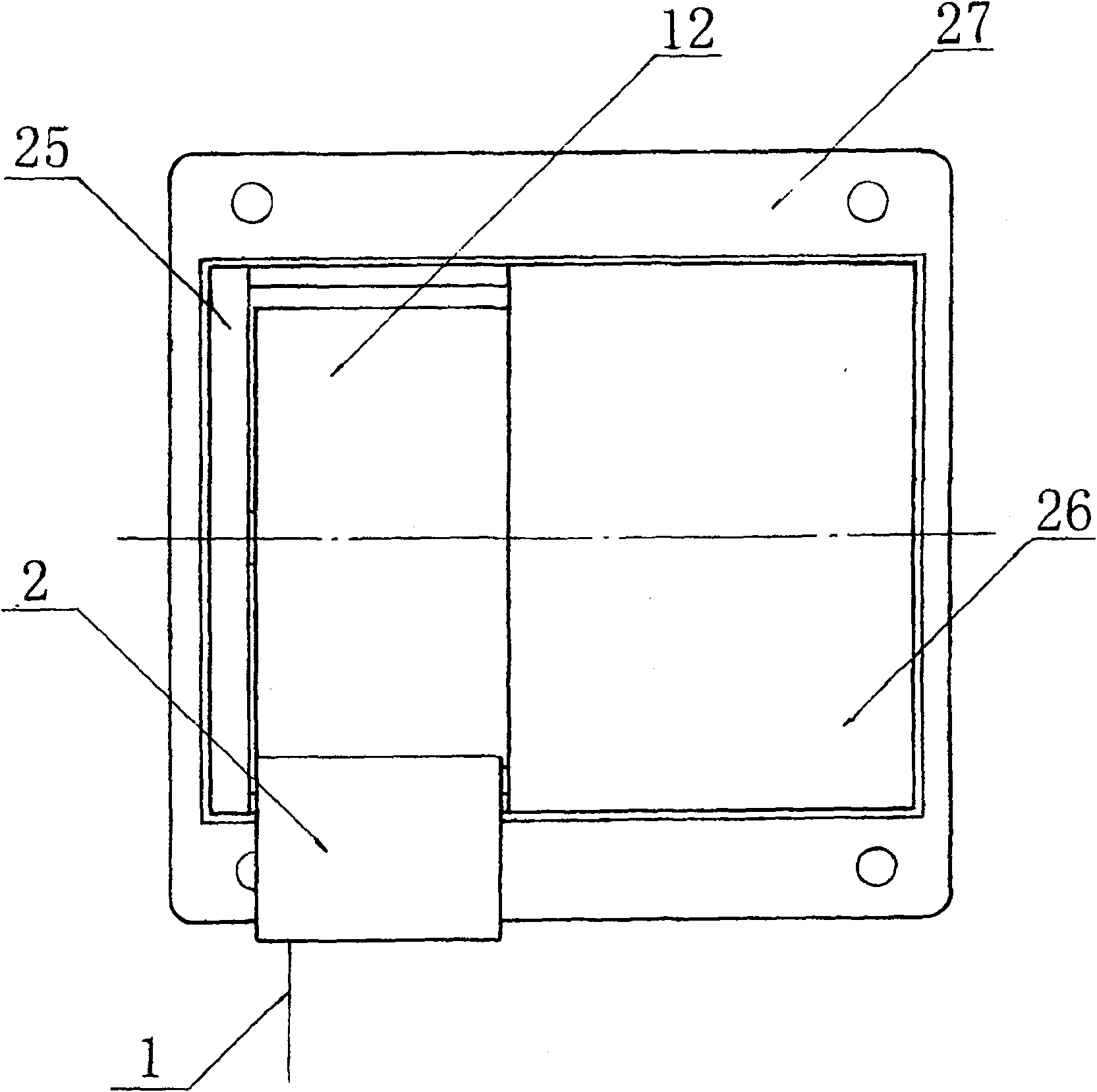

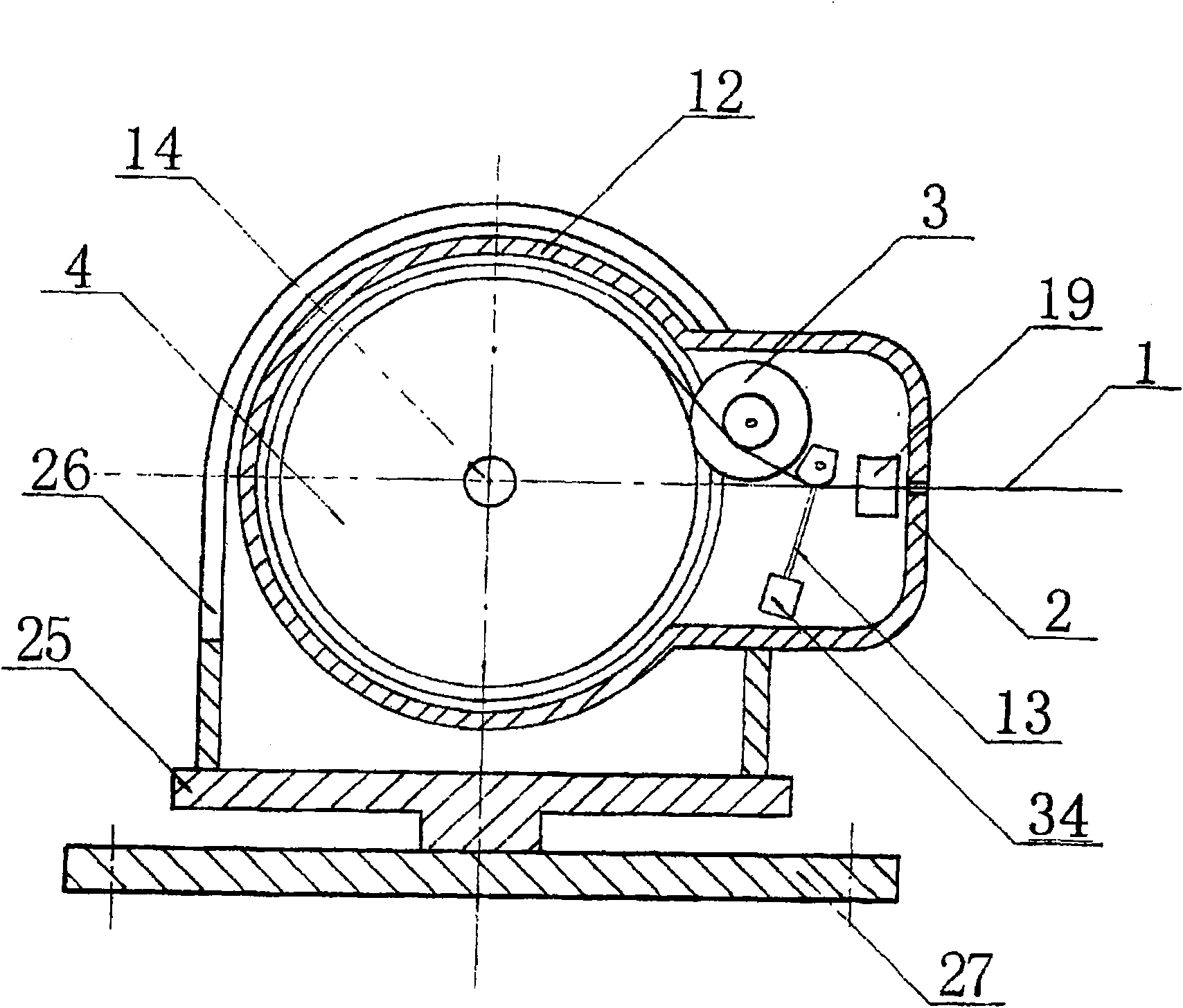

[0027] see Figure 1-9. A wire-drawing type photoelectric two-dimensional displacement sensor, including the wire steel wire 1 of the first part of the photoelectric wire displacement sensing device, the wire nozzle 2, the wire thinner 3, the wire reel 4, the coil spring 5, the gear set 7, the driving gear 8, the switch Wheel 9, trough-type photoelectric interrupter 10, stepping micromotor 11, frame 12, photoelectric line displacement microswitch 13, gear set 15 of the second part photoelectric angular displacement sensing device, photoelectric angular displacement microswitch 19 , driving gear 21, switching wheel 22, groove type photoelectric interrupter 33, step micromotor 23, frame 24, and chassis frame 25, casing 26 and base 27. The wire wire 1 is pulled out or retracted from the mouth hole of the wire nozzle 2 placed on the frame 12 of the first part photoelectric displacement sensing device, the wire wire 1 is coiled on the wire reel 4 through the wire nozzle 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com