Rust remover of motorcycle axle

A rust-removing machine and axle technology, which is applied to grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of not being able to automatically remove rust on locomotive axles, and achieve the effects of simple structure, low cost and good practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

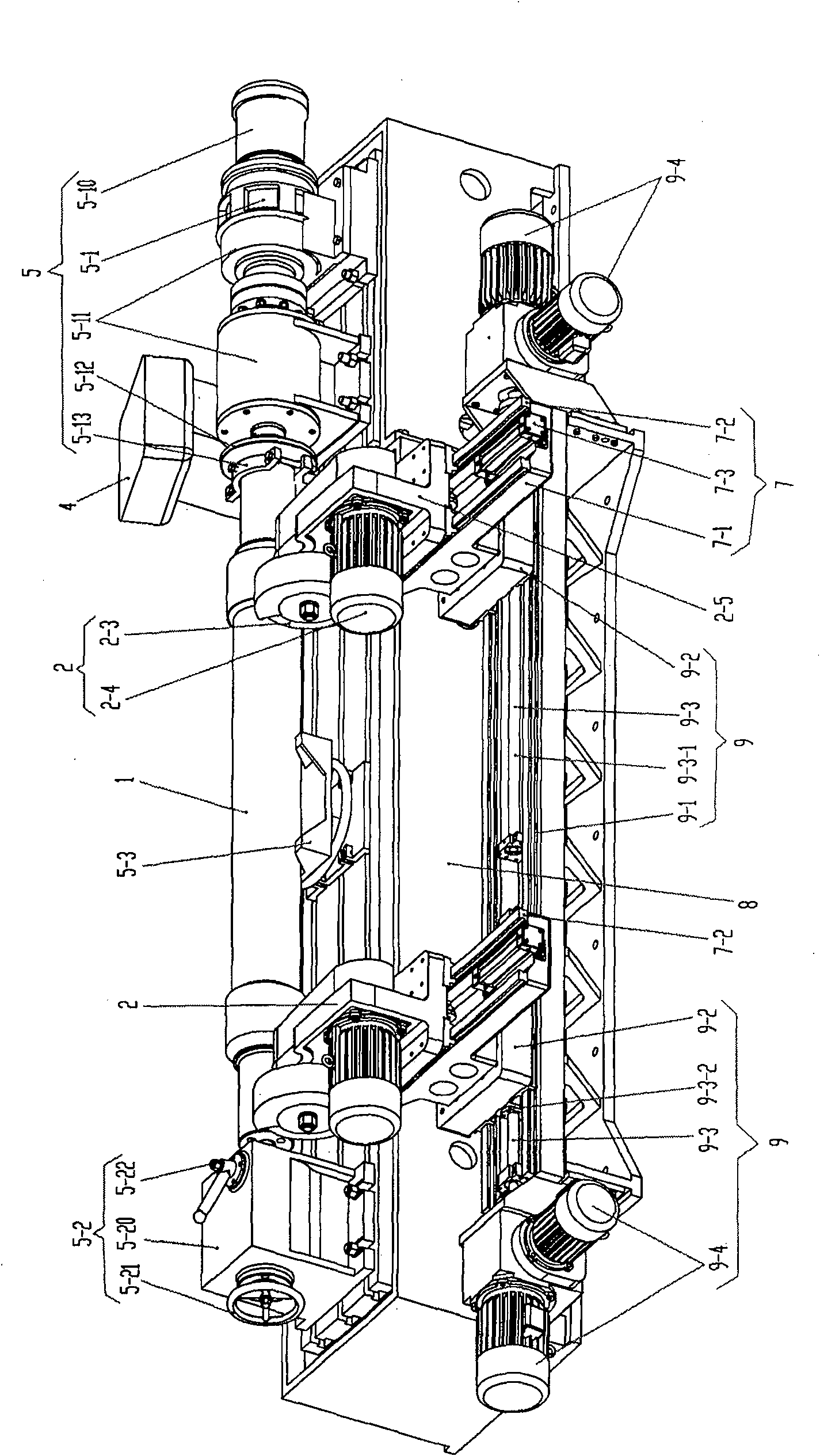

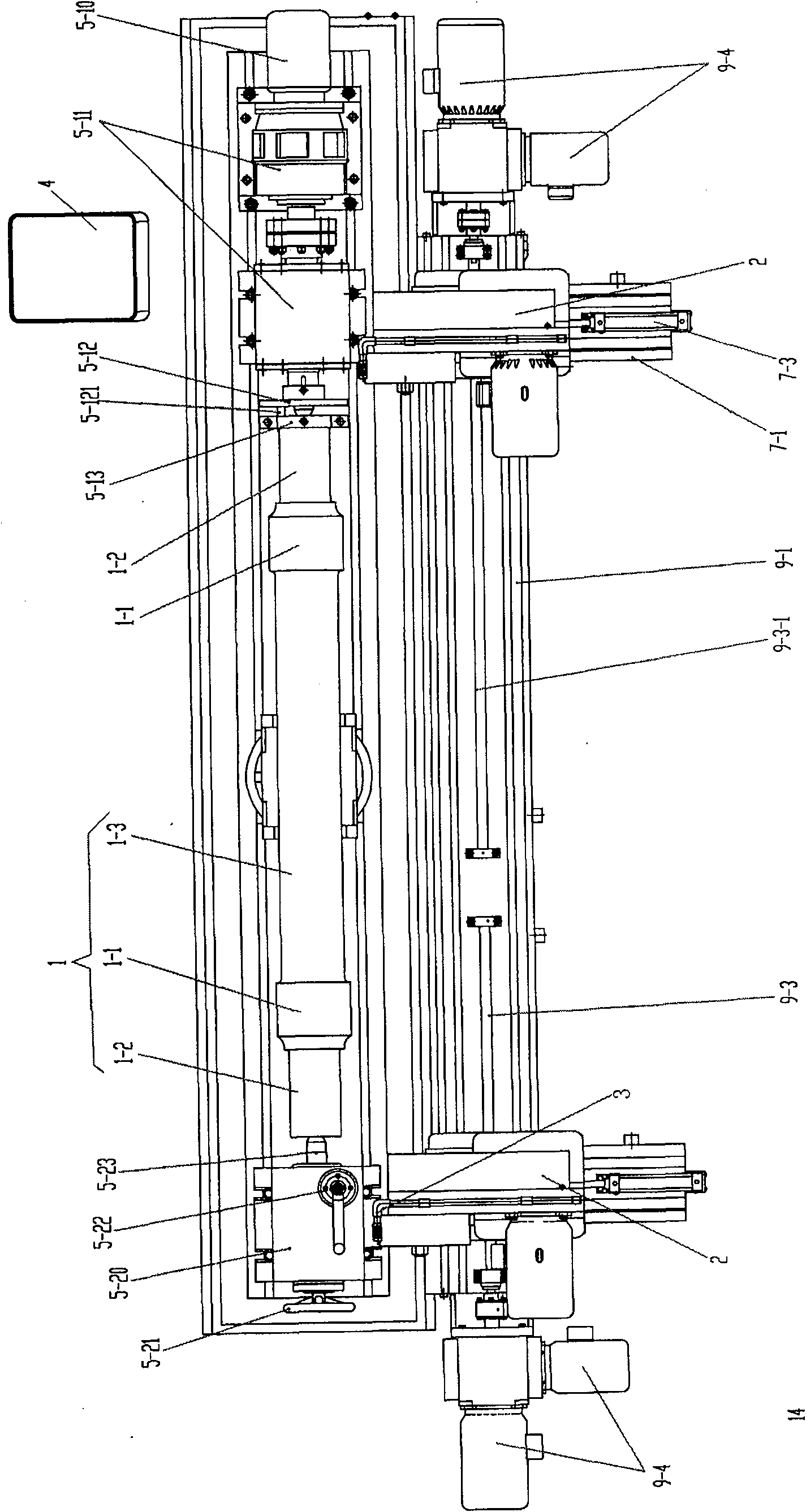

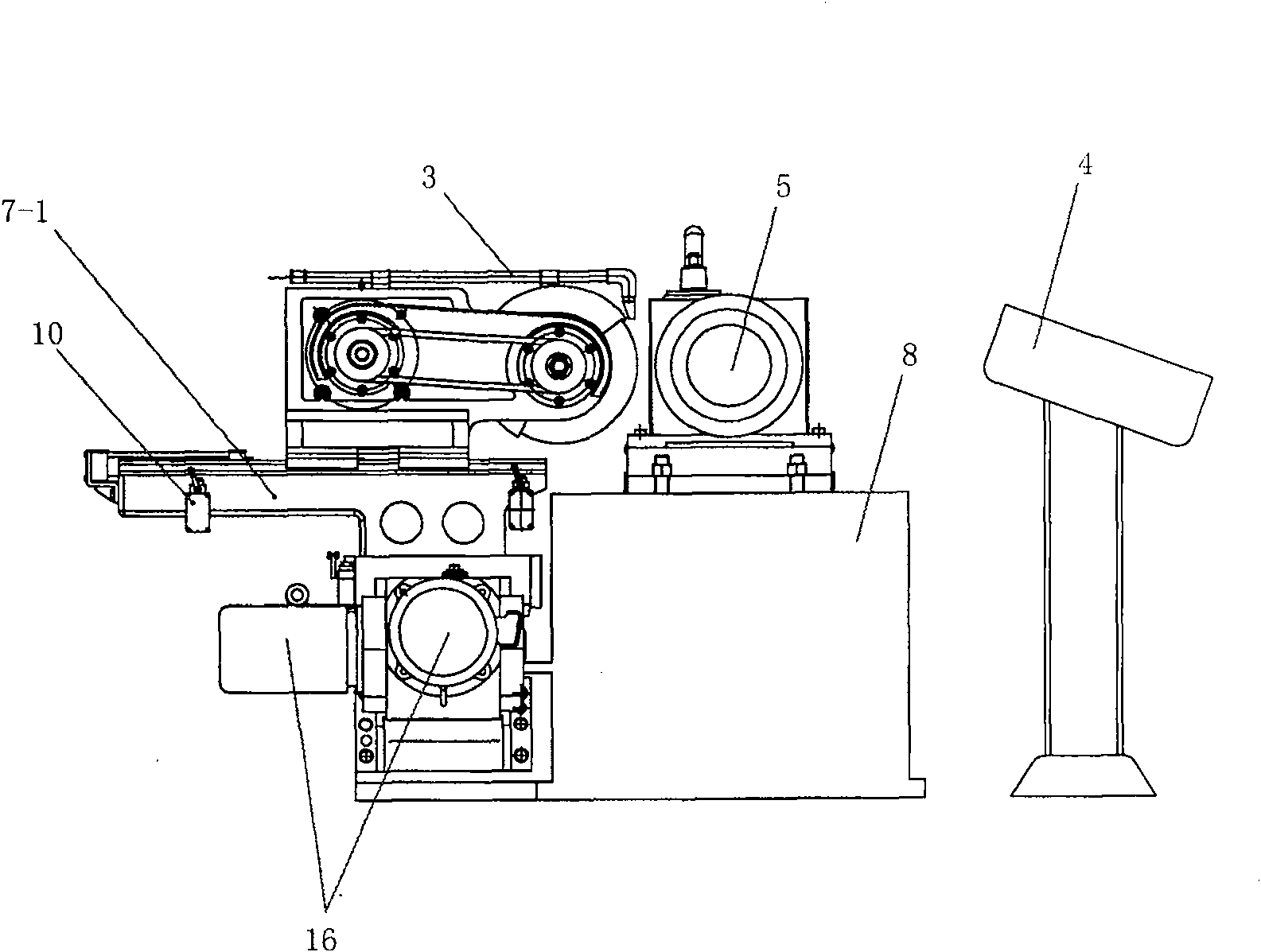

[0025] see Figure 1-6 , The locomotive axle rust remover of this embodiment includes: a machine bed 8 for placing the axle 1, an axle transmission device 5 arranged on the machine bed 8 for driving the axle 1 to rotate in the axial direction, and an axle transmission device 5 arranged on the axle 1. The turbine 2 on the side; the turbine 2 is provided on the first displacement device 7, and the first displacement device 7 is provided on the second displacement device 9; the first displacement device 7 is used to drive the turbine 2 along the axial direction of the axle 1 Vertical direction for linear displacement, the second displacement device 9 is used to drive the first displacement device 7 to make linear displacement along the axis of the axle 1; the thrower 2, the first displacement device 7 and the second displacement device 9 are controlled by an automatic control device 4 control.

[0026] The axle transmission device 5 includes: an axle rotation driving device 5-1 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com