Parallel methyl ester method for fats and oils in high acid value

A high-acid value oil and methyl esterification technology, which is applied in the field of oil processing, can solve the problems of large waste water discharge, low production efficiency, and slow reaction speed, and achieve the effects of less waste water discharge, full equipment utilization, and increased reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

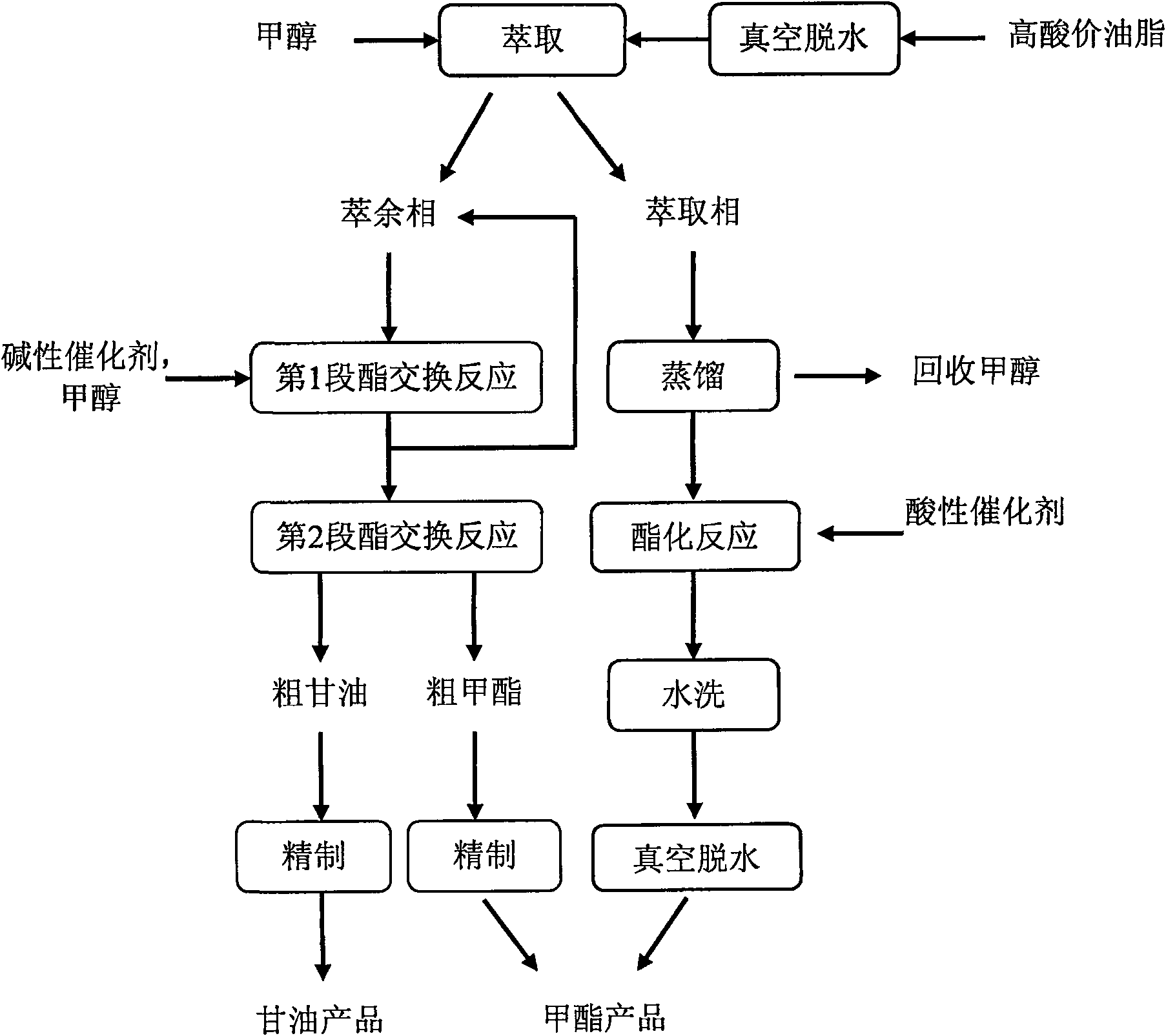

Method used

Image

Examples

Embodiment 1

[0022] (1) After the acidified oil with an acid value of 100 mgKOH / g is vacuum dehydrated to make the water content lower than 0.1%, methanol with 1.5 times the volume is used as the extraction agent and extracted 6 times at 32° C. to obtain a product enriched in free fatty acids an extract phase and a raffinate phase enriched in triglycerides, wherein the acid value of the raffinate phase is 0.8 mgKOH / g;

[0023] (2) Carry out following reaction respectively:

[0024] a) adding oily 3% concentrated sulfuric acid to the extract phase as a catalyst, reacting at 60°C for 5 hours to carry out methylation reaction to obtain crude fatty acid methyl ester;

[0025] b) Add calcium oxide with an oil weight of 0.8% to the raffinate phase as a catalyst, control the molar ratio of methanol and triglyceride to 3:1, react at 60° C. for 50 minutes, and obtain an intermediate product with a conversion rate of 35%. 50% (by mass, the same below) of the intermediate product was mixed with the ...

Embodiment 2

[0028] (1) Crude oil with an acid value of 40mgKOH / g is used as a raw material, and in a countercurrent rotary disk extraction tower, 1.5 times the mass of methanol is continuously extracted as an extractant to obtain an extract phase enriched in free fatty acids and a raffinate enriched in triglycerides phase, wherein the acid value of the raffinate phase is 0.9mgKOH / g. Part of the methanol is recovered from the extract phase through the evaporator, and the molar ratio of methanol to free fatty acid is controlled to be 25:1;

[0029] (2) Carry out following reaction respectively:

[0030] a) adding oily 3% concentrated sulfuric acid to the extract phase as a catalyst, reacting at 70° C. for 5 hours to carry out methylation reaction to obtain crude fatty acid methyl ester;

[0031] b) Add the calcium oxide / magnesia composite catalyst of 0.9% oil weight and the fatty acid methyl ester, fatty acid monoglyceride and fatty acid diglyceride mixture of oil weight 10% in the raffina...

Embodiment 3

[0034] (1) Crude oil with an acid value of 60mgKOH / g is used as a raw material, and in a countercurrent rotary disk extraction tower, methanol is used as an extraction agent with twice the mass for continuous extraction to obtain an extract phase enriched in free fatty acids and a raffinate enriched in triglycerides Phase, wherein the acid value of the raffinate phase is 1mgKOH / g. Part of the methanol is recovered from the extract phase through the evaporator, and the molar ratio of methanol to free fatty acid is controlled to be 30:1;

[0035] (2) Do not carry out the following reactions:

[0036] a) adding oily 3% concentrated sulfuric acid to the extract phase as a catalyst, reacting at 60°C for 5 hours to carry out methylation reaction to obtain crude fatty acid methyl ester;

[0037] b) in the raffinate phase, add the sodium hydroxide of 0.9% of oil weight as catalyst and the mixture of fatty acid methyl ester, fatty acid monoglyceride and fatty acid diglyceride of oil w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com