Method for welding parts

A technology for parts and welding parameters, applied in the field of ultrasonic welding, which can solve problems such as temperature fluctuations and fluctuations in the quality of welding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention is explained below with the aid of a rope to be welded, but should not be restricted thereby. On the contrary, the invention also extends to the welding of plastic parts.

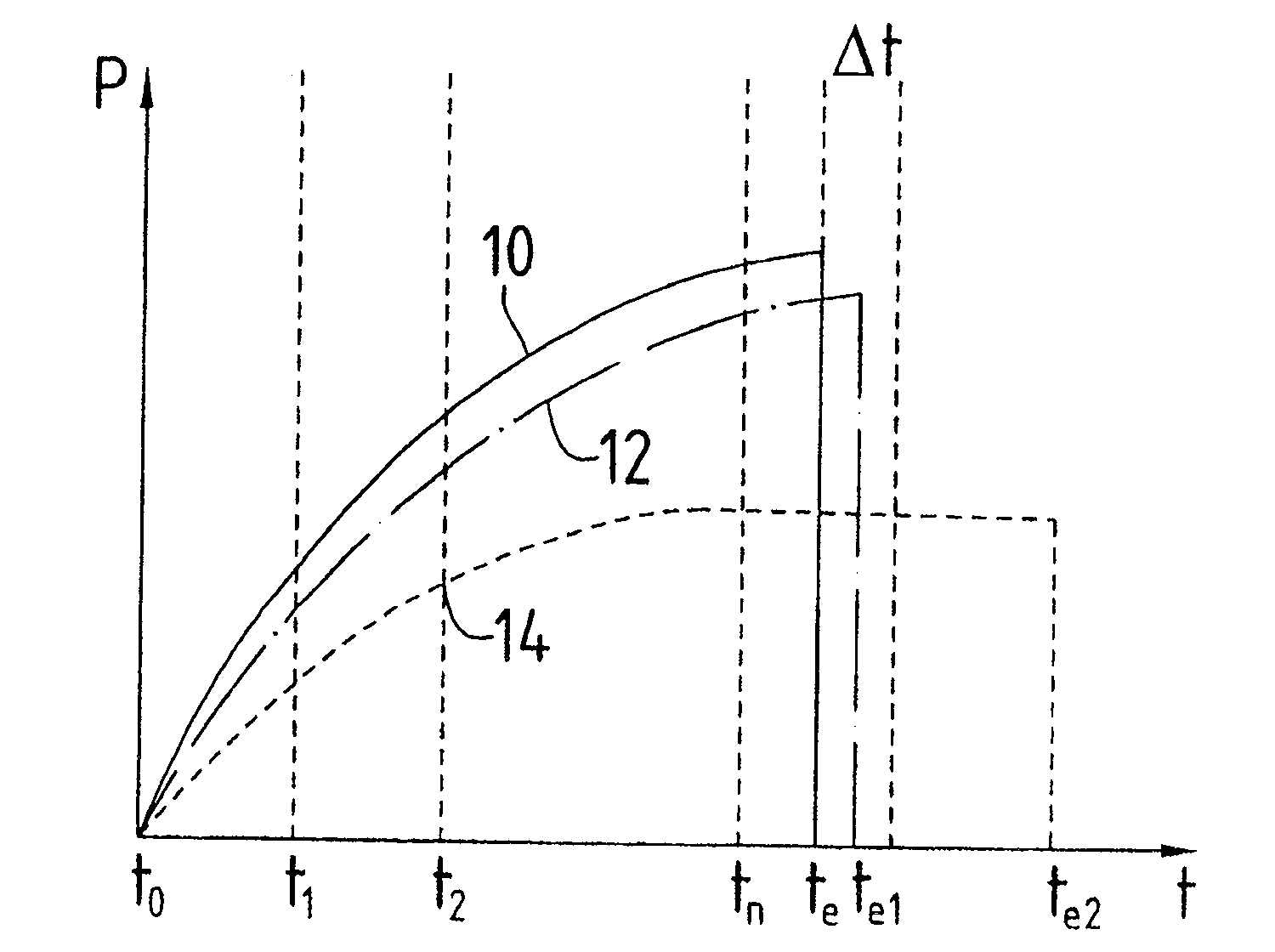

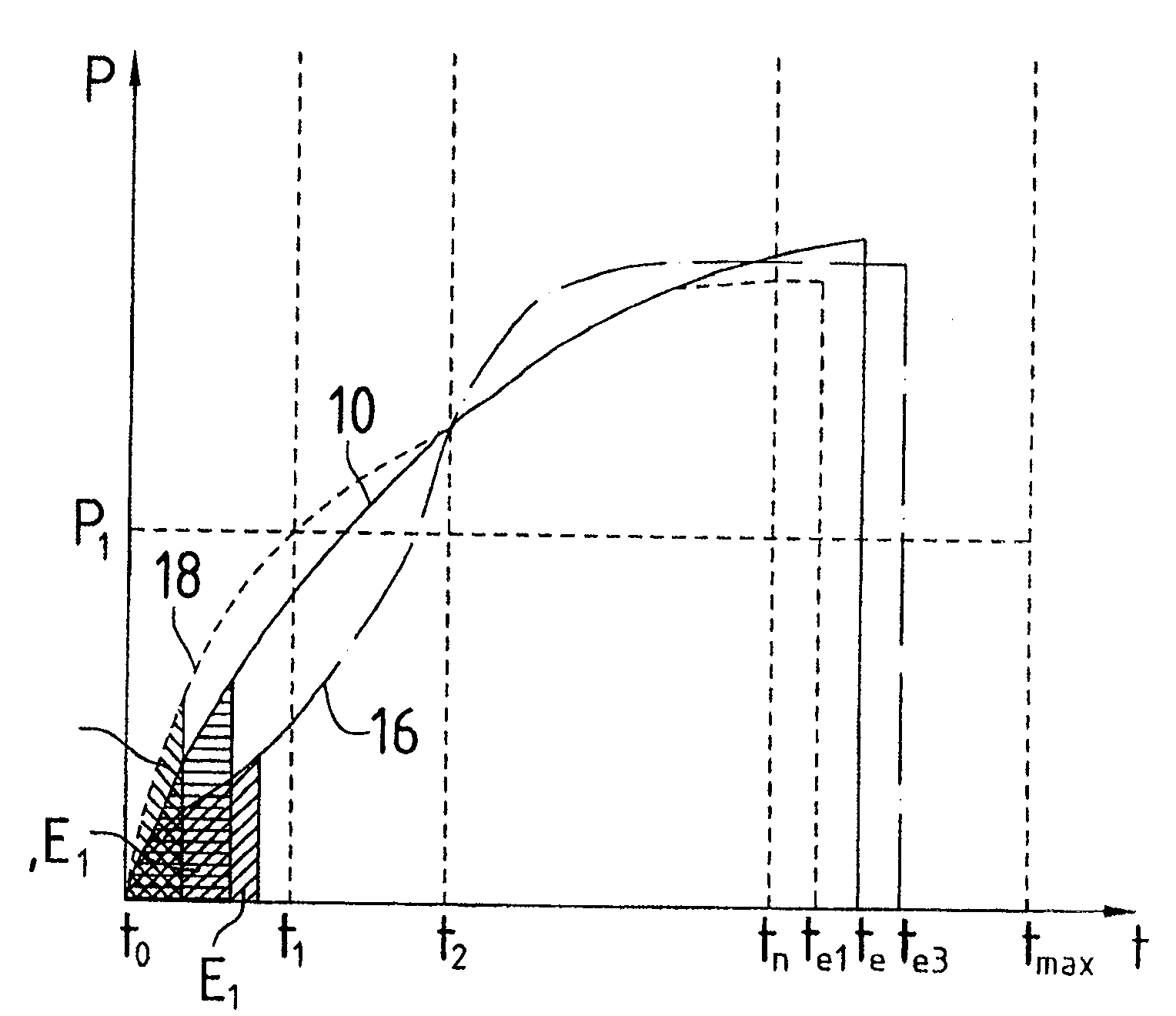

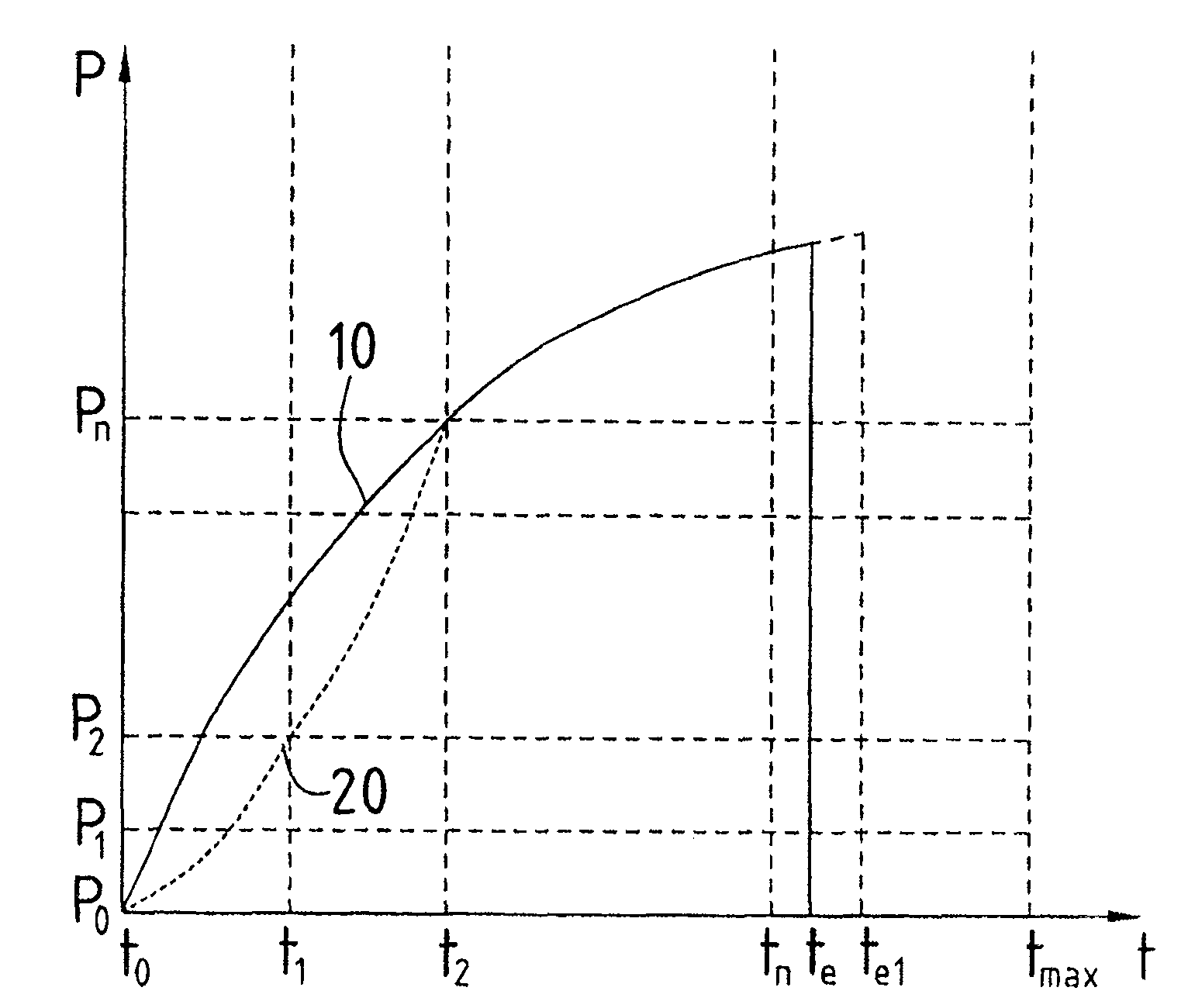

[0036] In order to weld a cable by means of ultrasound according to the prior art, values stored in a memory relating to, for example, pressure, amplitude, tool size and energy input are called based on its overall cross section. Welding of the rope is then carried out in which a power-time curve is established from figure 1 It can be seen and is marked with the reference number 10 . Therefore, the area under the correspondingly drawn curve 10 corresponds to the energy input represented by:

[0037] E = ∫ t = 0 t = te Pdt

[0038] where P = power and t = time.

[0039] In this embodiment, the curve 10 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com