Tyre non-circularity measuring method

A measurement method and tire technology, applied in the field of measurement, can solve problems such as backward detection equipment, unstable detection results, and lack of testing process guidance

Active Publication Date: 2009-11-25

MESNAC

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, in the existing tire production and testing process, there is no comprehensive and targeted theoretical support and specific measurement methods. Therefore, there is a certain blindness in the measurement of out-of-roundness, lack of intuitive testing process guidance, and tire out-of-roundness measurement. The detection equipment is outdated and the detection results are unstable, which in turn affects the safe driving of motor vehicles

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

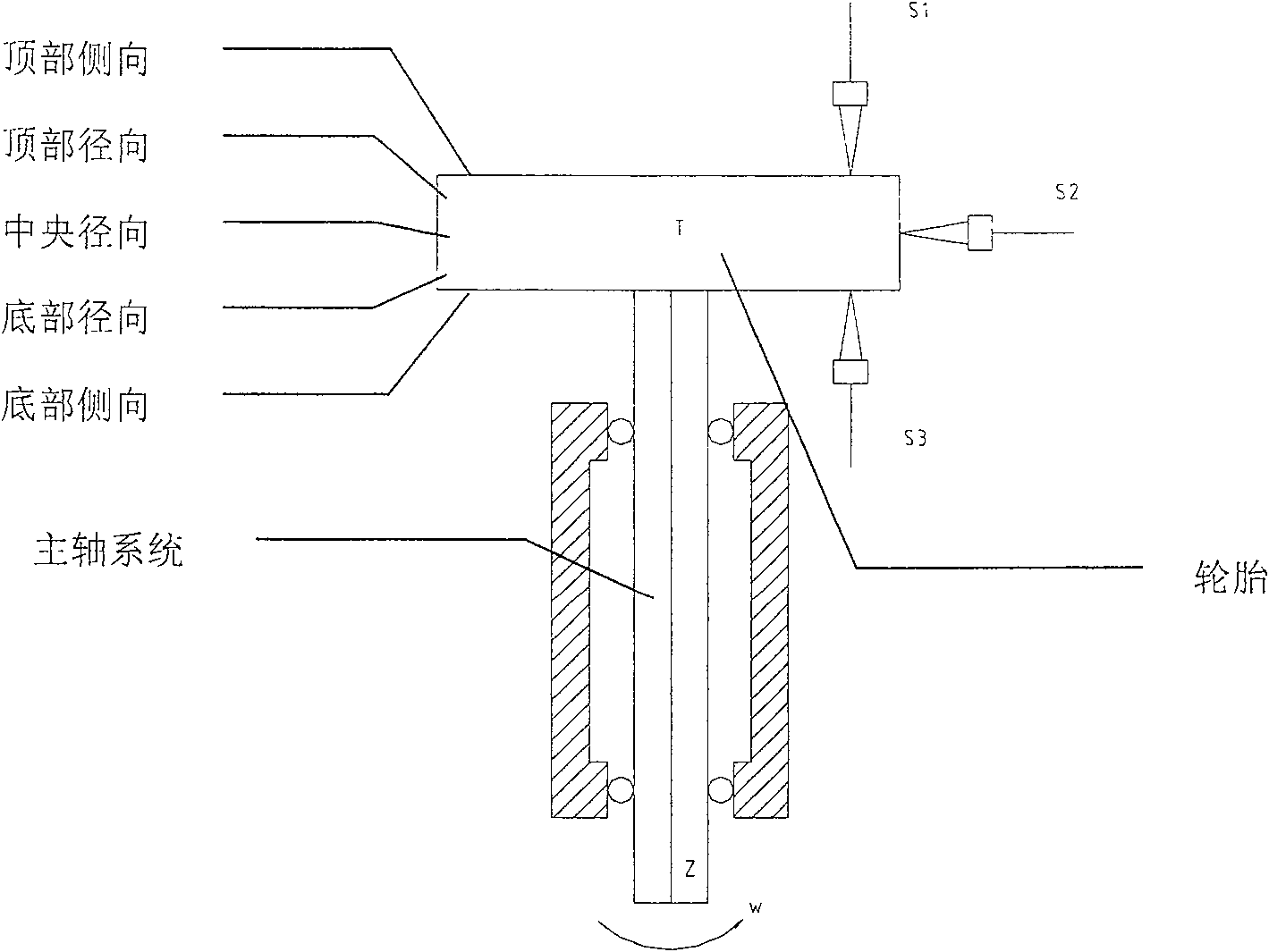

[0066] Example 1, such as figure 1 As shown, the measuring method of the tire out-of-roundness of the present invention is mainly aimed at the following factors that produce and affect the out-of-roundness of the tire, namely the beating of the tire sidewall, the bulge of the tire sidewall, the depression of the tire sidewall, the tire shoulder The beating of the tire tread.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

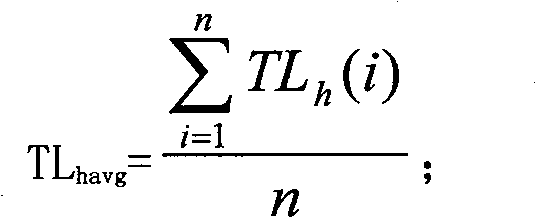

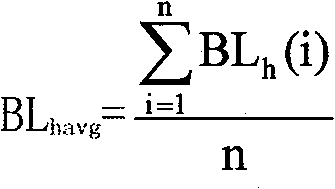

The method for measuring tire out-of-roundness described in the present invention measures and calibrates tire profile parameters to intuitively and comprehensively detect the out-of-roundness index and provide it to the process quality department to analyze the degree of tire geometric deformation. In the process of tire building, due to the belt layer affecting the deformation of the tread and the uneven thickness of the tire wall, the tread is raised and sunken. The establishment can reflect the tire out-of-roundness caused by the material and manufacturing process, which is reflected in the unevenness of the tire. The parameters that must be checked during the roundness inspection process include top lateral deviation, top radial deviation, central radial deviation, bottom radial deviation, bottom lateral deviation, top bulge, top sag, bottom bulge and bottom sag.

Description

technical field [0001] The invention relates to a measuring method, in particular to a method for measuring and calibrating multiple parameters involved in tire out-of-roundness. Background technique [0002] Tires are the main action-executing components of motor vehicles. The stability of tire performance and compliance with safety design standards will directly determine the safety of personnel using motor vehicles. The tire is a circular rotatable body with a cylindrical section, which is made of multi-layer rubber prefabricated materials with steel cords and composite rubber prefabricated materials through lamination, molding, vulcanization and setting. The tire with the above structure inevitably has problems such as uneven density and geometric deformation in its constituent materials, which is often referred to as tire out-of-roundness. According to relevant mechanical principles, tires with a certain degree of deformation will inevitably produce alternating radial ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M17/02G01B21/00

Inventor 孟鹏都强晏建文

Owner MESNAC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com