Rear separating rolling mechanism of servo motor drived comber

A technology for separating rollers and servo motors, which is used in combing machines, textile and papermaking, fiber processing, etc. The effect of improving yarn quality, reducing intermediate gear transmission links, and improving motion transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

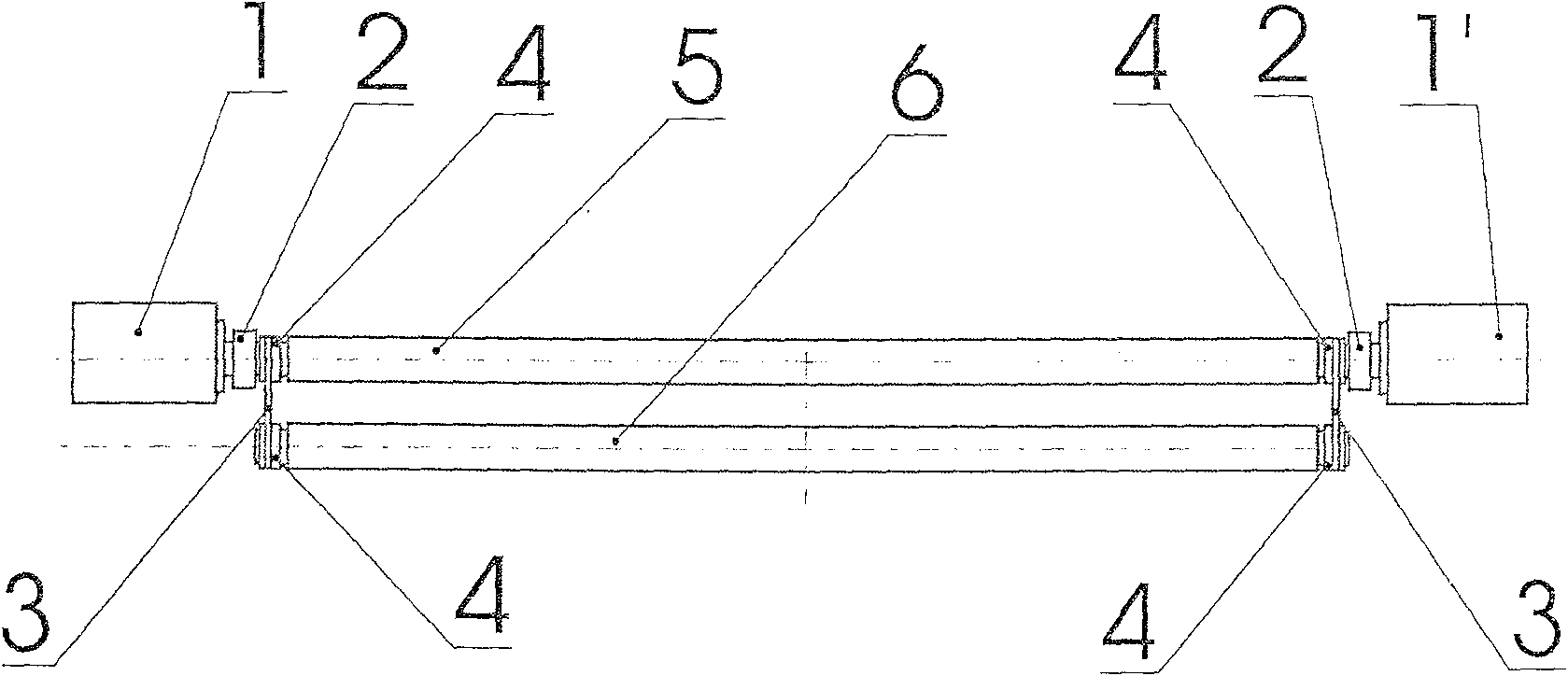

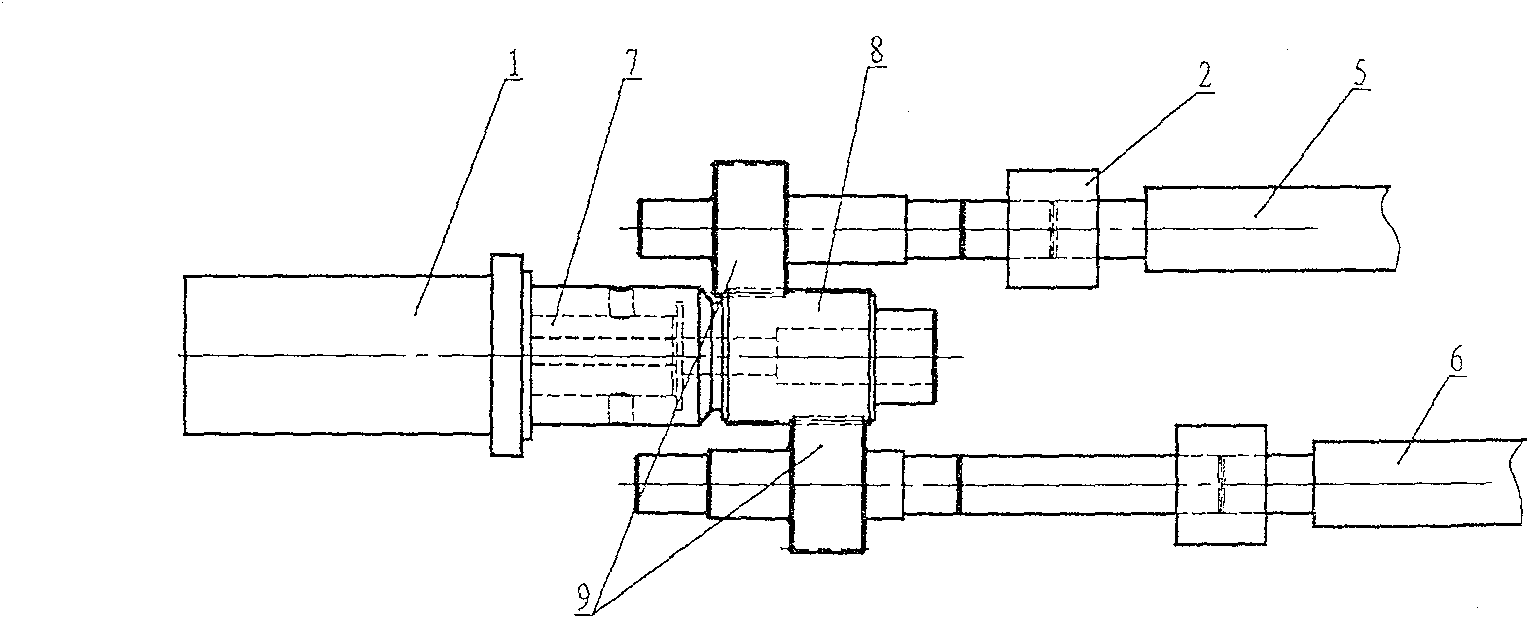

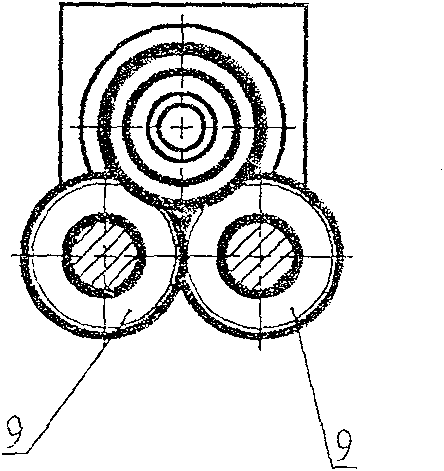

[0018] Such as figure 1 The rear separation roller mechanism of the combing machine driven by the servo motor shown is a creative improvement of the existing separation roller mechanism of the combing machine driven by the servo motor. The specific solution is: two servo motors 1, 1 ′. It is composed of the rear separation roller 5 and the front separation roller 6, characterized in that: the front separation roller 6 and the rear separation roller 5 are each a continuous and complete body, wherein the rear separation roller 5 passes through the The left and right ends are respectively connected to the servo motors 1, 1'controlled by the same drive controller. While driving the rear separation roller, the servo motors 1 and 1'also pass through the two synchronously fixed ends of the rear separation roller. The belt wheel 4 and the set synchronous belt 3 are connected with the synchronous belt wheels 4 fixed at the two ends of the front separating roller 6, and the separating roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com