Double crossed vehicle running track

A vehicle driving and track technology, which is applied to the track field of rail vehicles, can solve the problems of high positional accuracy requirements, high manufacturing costs, and inability to carry out continuous bearing surfaces, and achieves improved axial positioning accuracy, high axial positioning accuracy, Low frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments are given below in conjunction with the accompanying drawings, and the vehicle running track with a "convex"-shaped end face of the present invention will be further described in detail.

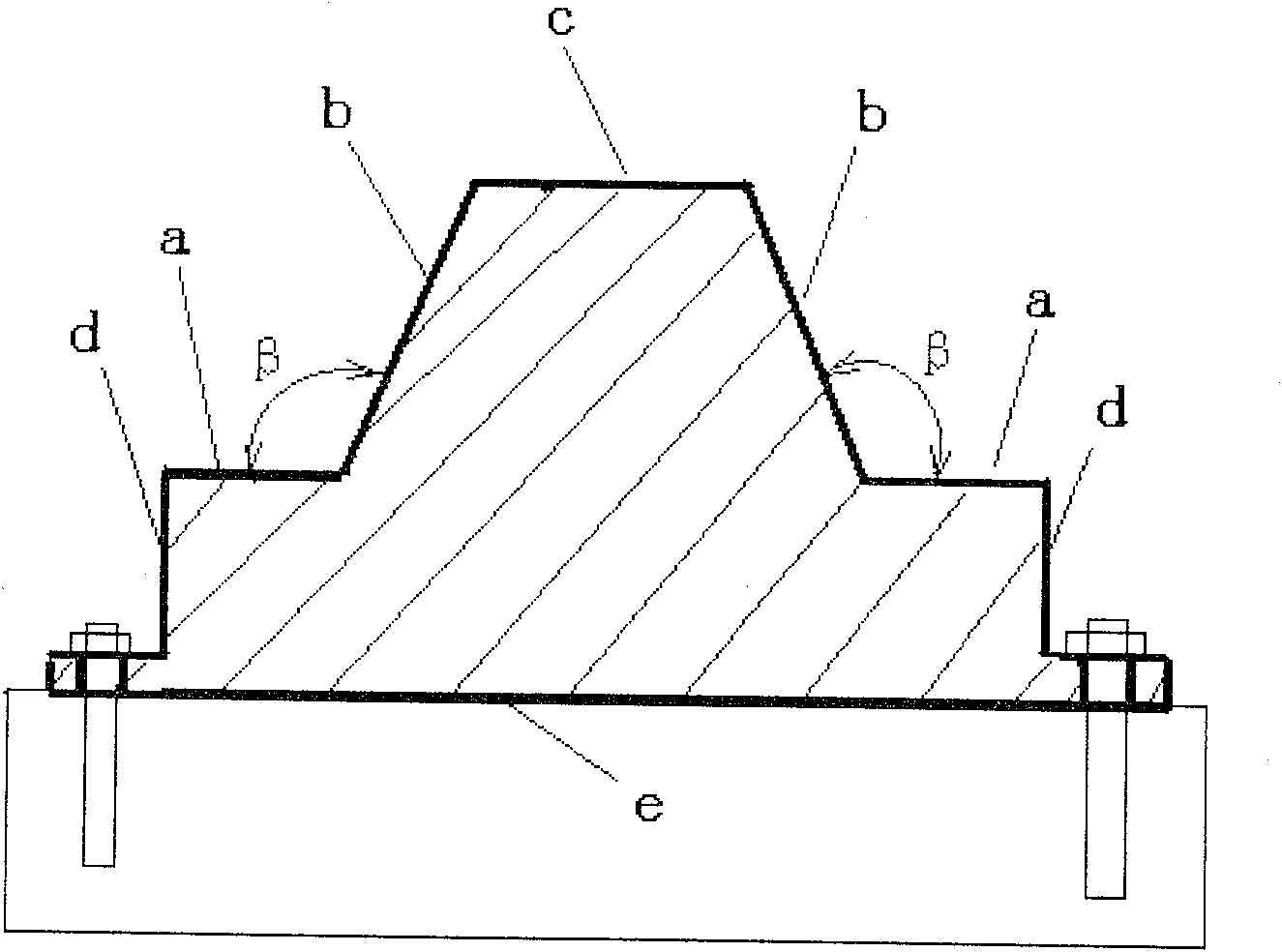

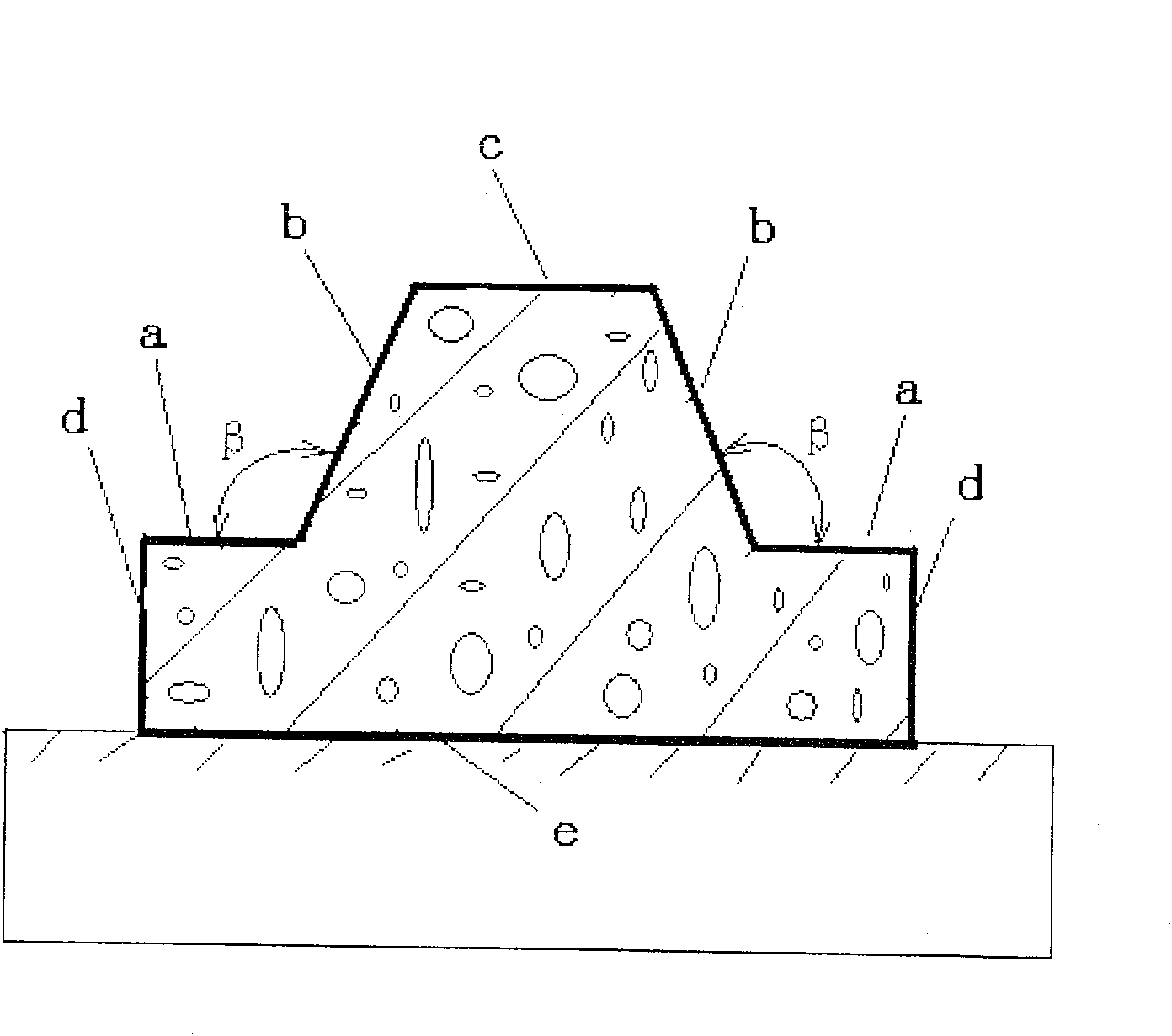

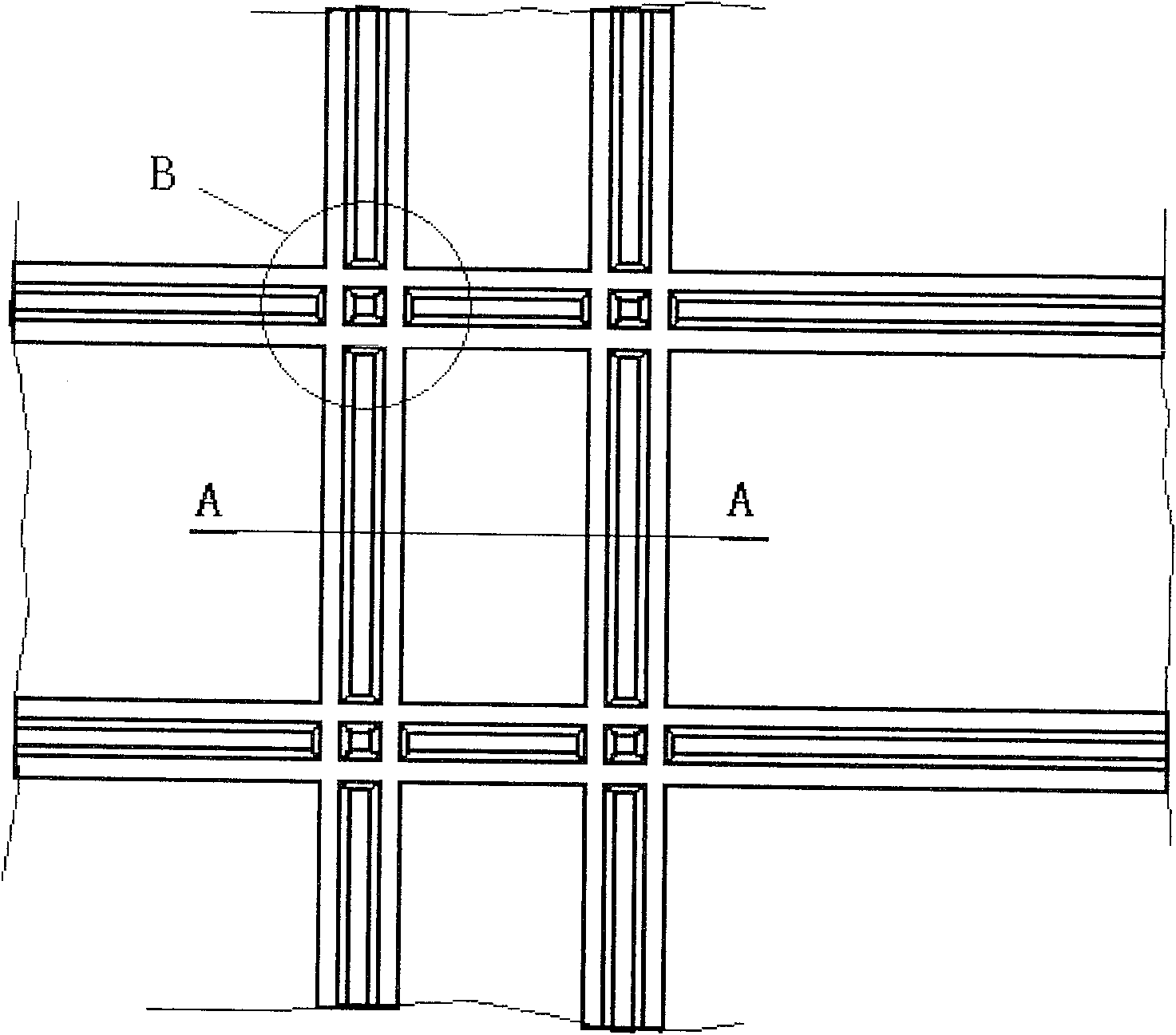

[0024] see figure 1 , image 3 , Figure 4 with Figure 5 , according to the above-mentioned technical scheme, the "well"-shaped vehicle running track of the present invention is made of cement, including two sets of load-bearing surfaces for carrying the weight of the wheels and the vehicle, a limiting surface and side surfaces for limiting the axial displacement of the wheels, a top surface and The bottom surface has a "convex" cross-section, and the angle β between the bearing surface and the limiting surface is 120° on both sides, and the cross-section is left-right symmetrical. This structure can omit a track when more than two working surfaces are adjacent, such as Figure 7 shown.

[0025] The second embodiment of the "well"-shaped vehicle running trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com