Large range moving magnetic suspension planar working table

A flat workbench, a large-scale technology, applied in the direction of workbench, manufacturing tools, instrument parts, etc., to achieve the effect of increasing the relative stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

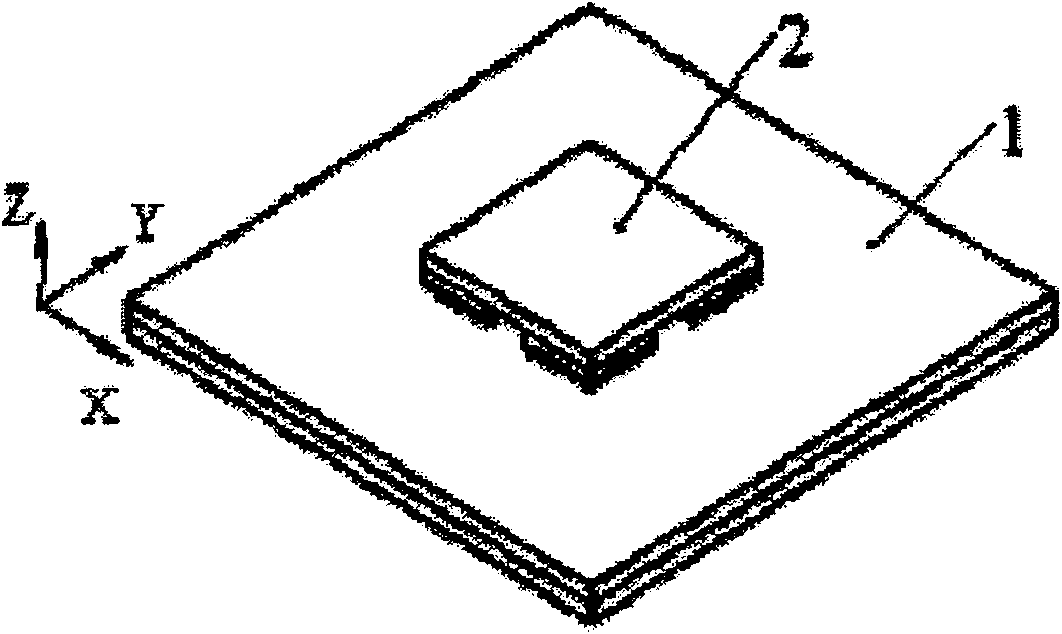

[0025] figure 2 It is a three-dimensional view of the maglev planar workbench of the present invention. It can be seen from the figure that the workbench of the present invention is composed of a base 1 and a mobile platform 2. Wherein, the base station 1 is composed of a base 3 and a planar permanent magnet array 5 arranged on the base 3, and the mobile station 2 is composed of a platform 7 and a mobile electromagnetic structure 8 placed on the bottom surface of the platform 7, as image 3 As shown, this figure is a side view of the magnetic levitation XY workbench of the present invention.

[0026] The planar permanent magnet array 5 is composed of a series of permanent magnets 6 arranged staggeredly on the base 3 according to the magnetization direction, Figure 4 A form of the planar permanent magnet array 5 and its installation relationship with the base 3 are given. In the figure, the rectangular parallelepiped permanent magnet 6 is magnetized along the vertical direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com