High pressure or middle pressure rotating connector and marine structure

A rotary joint, high voltage technology, applied in the direction of rotary collectors, connections, collectors, etc., can solve the problems of dielectric oil pollution, maximum voltage limit, limit maximum voltage, etc., to achieve high dielectric strength, pollution reduction, insulation The effect of property retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

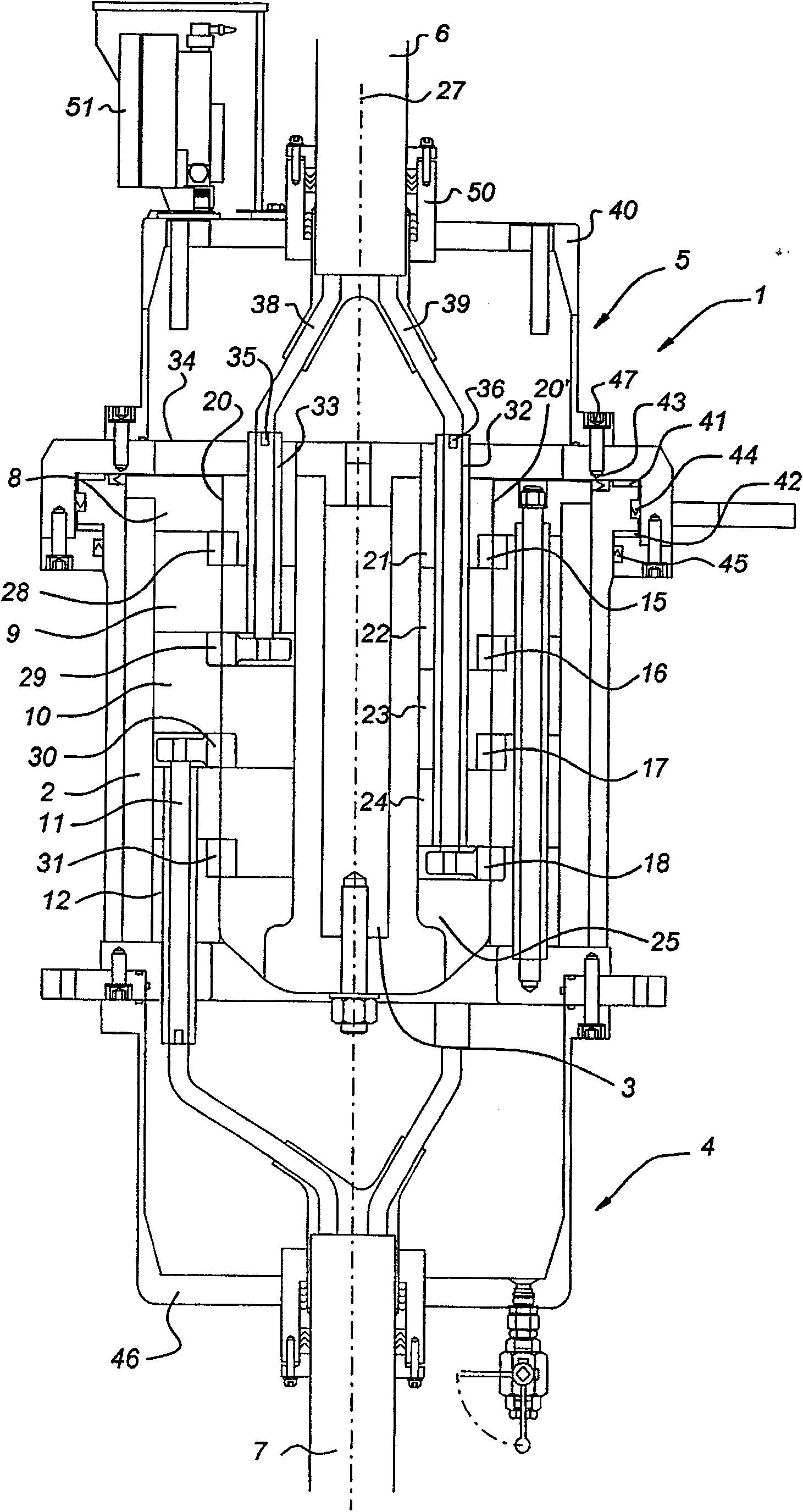

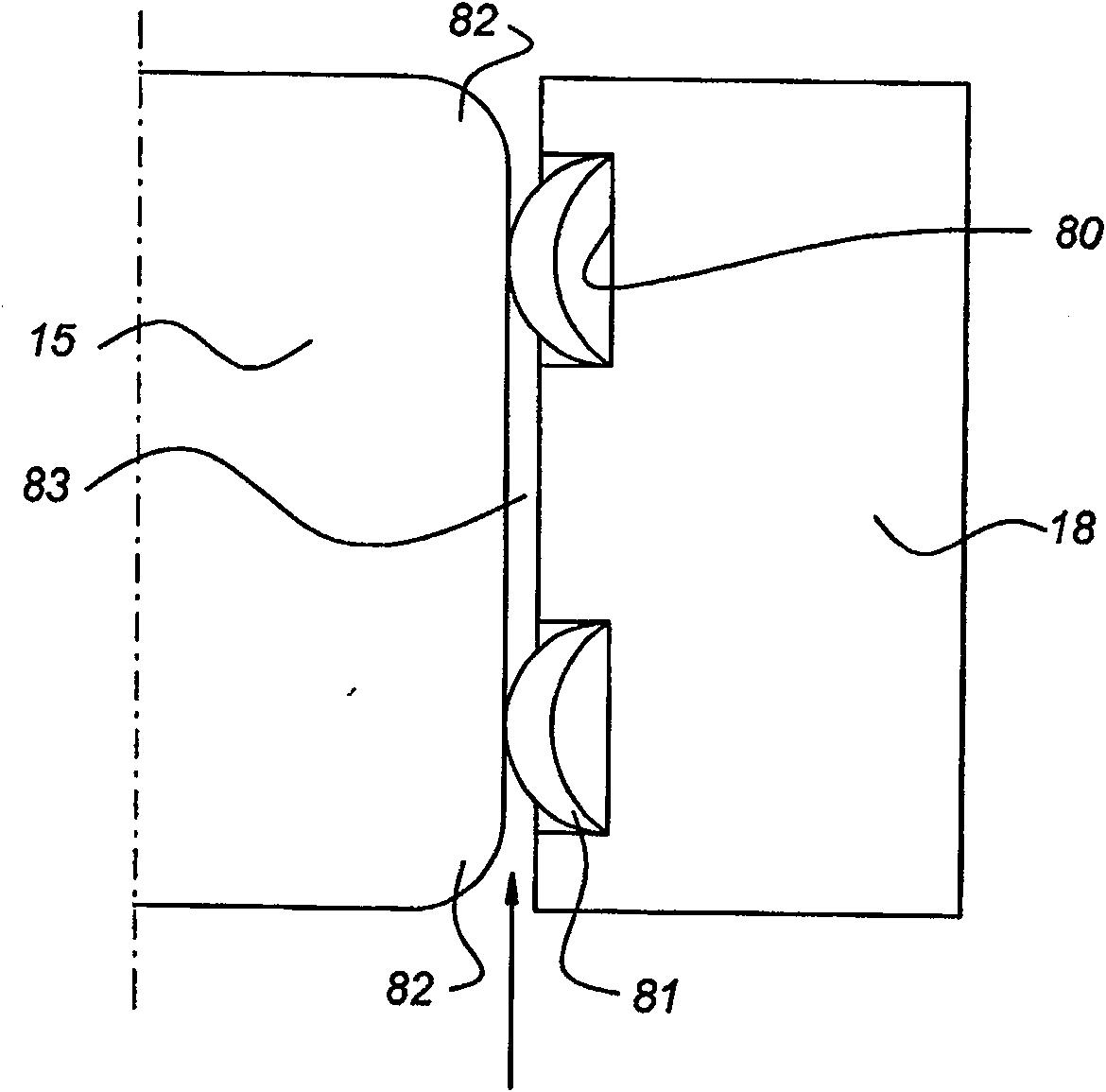

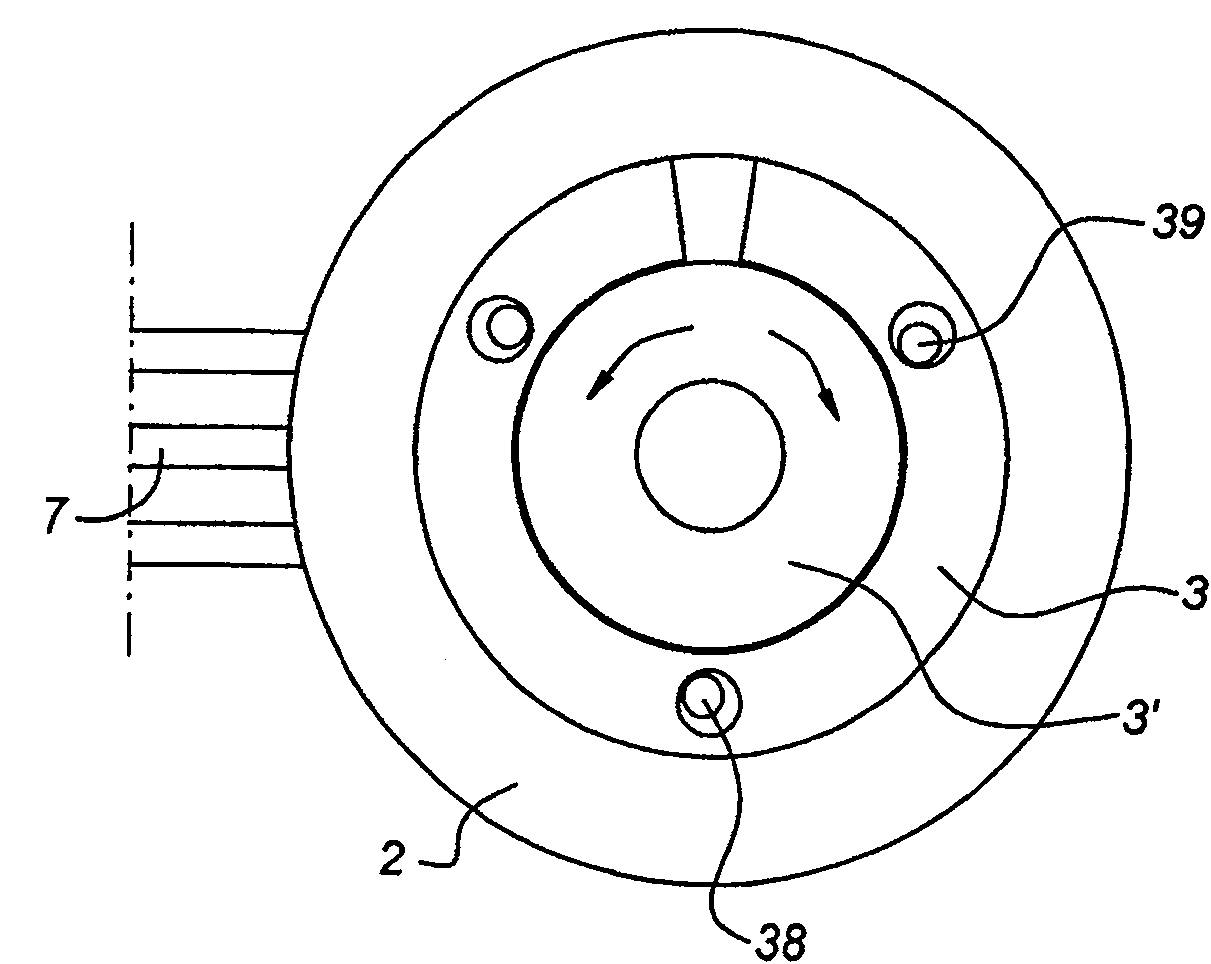

[0025] figure 1 Shown is a high pressure swivel 1 comprising a fixed outer annular wall 2 and an inner cylindrical support 3 . Said outer annular wall 2 is connected to top and bottom connector boxes 4, 5 for connecting three-phase cables 6, 7 respectively. Inside said annular wall 2 , five insulating rings 8 , 9 , 10 , 11 and 12 are arranged, which are fixed to the outer wall 2 . In each insulating ring 9 to 12, a recess is provided respectively, in which ring conductors 15, 16, 17, 18 are placed. The boundary surfaces of the outer insulating rings 8 to 11 are kept in contact with the boundary surfaces of the four inner annular insulators 21 to 24 fixed to the inner cylindrical element 3 . The inner annular insulators 21 to 24 and the cylindrical element 3 are rotatable about a longitudinal axis 27 . Conductors 28 to 31 are arranged in corresponding recesses of said respective insulating rings 21 to 24 . The respective conductors 28 to 31 are preferably formed from ring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com