DC supply system for container piling site tyre hoister

A technology for container yard and power supply system, which is applied in the field of DC power supply system for container yard tire cranes, can solve the problems of large smoke and dust pollution, waste, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

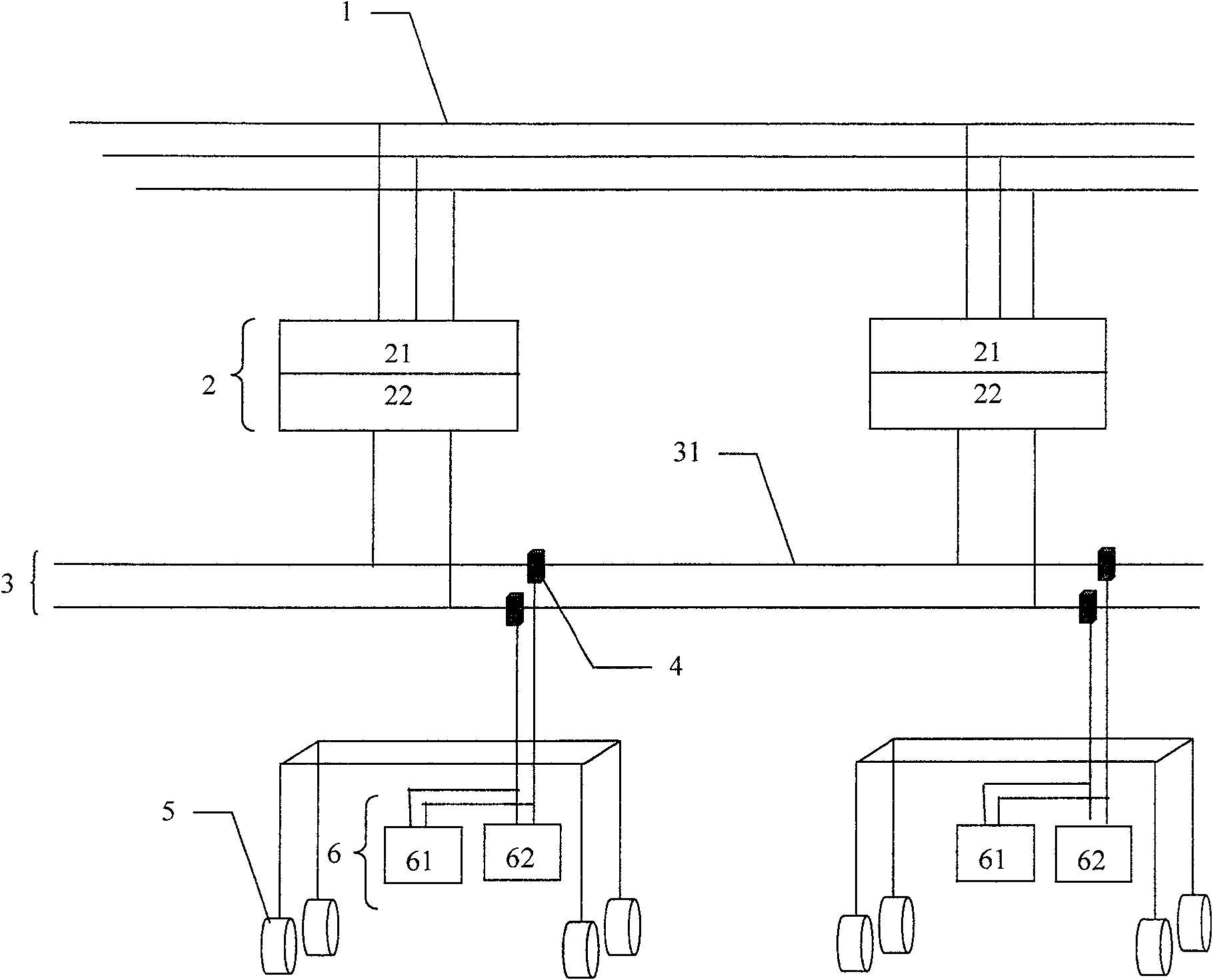

[0018] see figure 1 As shown, the DC power supply system of the tire crane in the container yard includes the power supply device and the power receiving device of the tire crane, wherein the power supply device of the tire crane includes at least one AC-DC conversion device 2 and a public DC bus grid 3 in the entire container yard , the public DC bus grid 3 is connected to a high-voltage AC power supply 1 through an AC-DC conversion device 2 .

[0019] At the same time, the power receiving device of the tire crane in the DC power supply system of the tire crane in the container yard includes at least one DC-AC conversion auxiliary power supply device 61 for each tire crane and a frequency conversion speed control device 62 with only inverter, and the DC-AC conversion auxiliary power supply device The frequency conversion speed regulating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com