Preparation process of hydroprocessing catalyst

A hydrotreating and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Aluminum particle size, alumina structure damage, etc., to reduce the loss of pore volume and specific surface, improve the performance, and the effect of concentrated pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

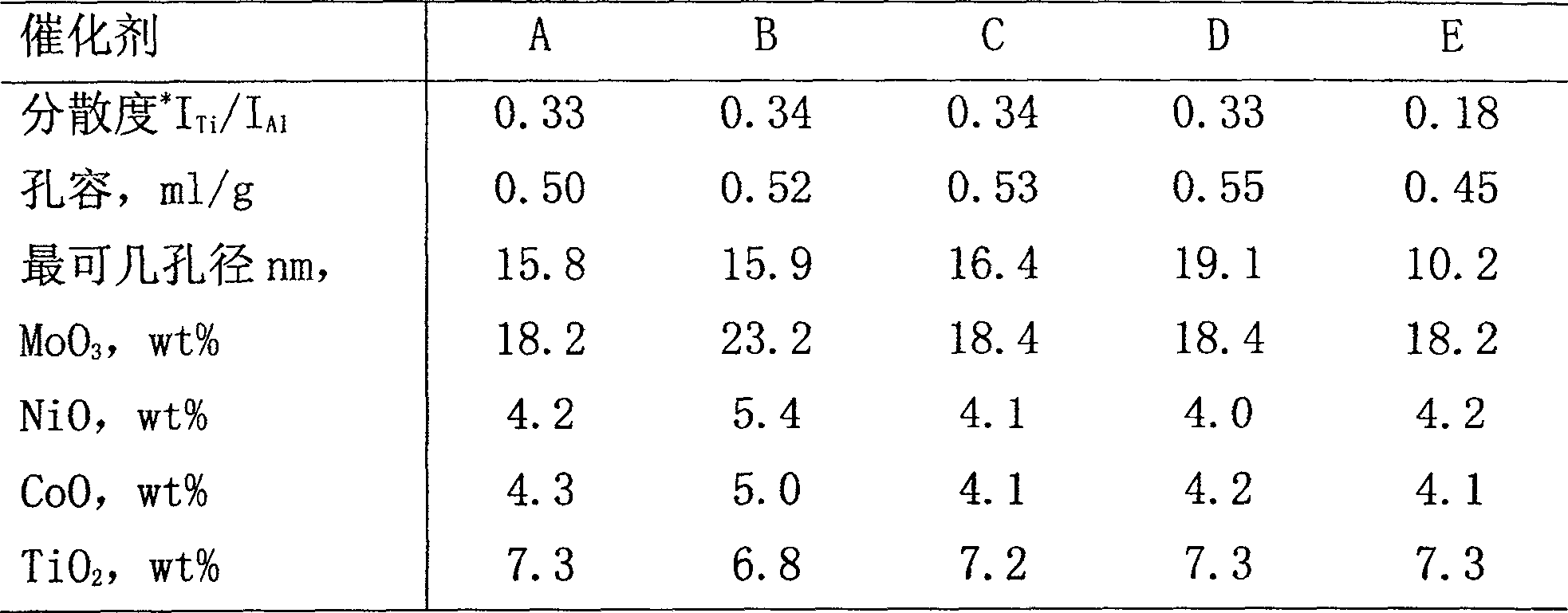

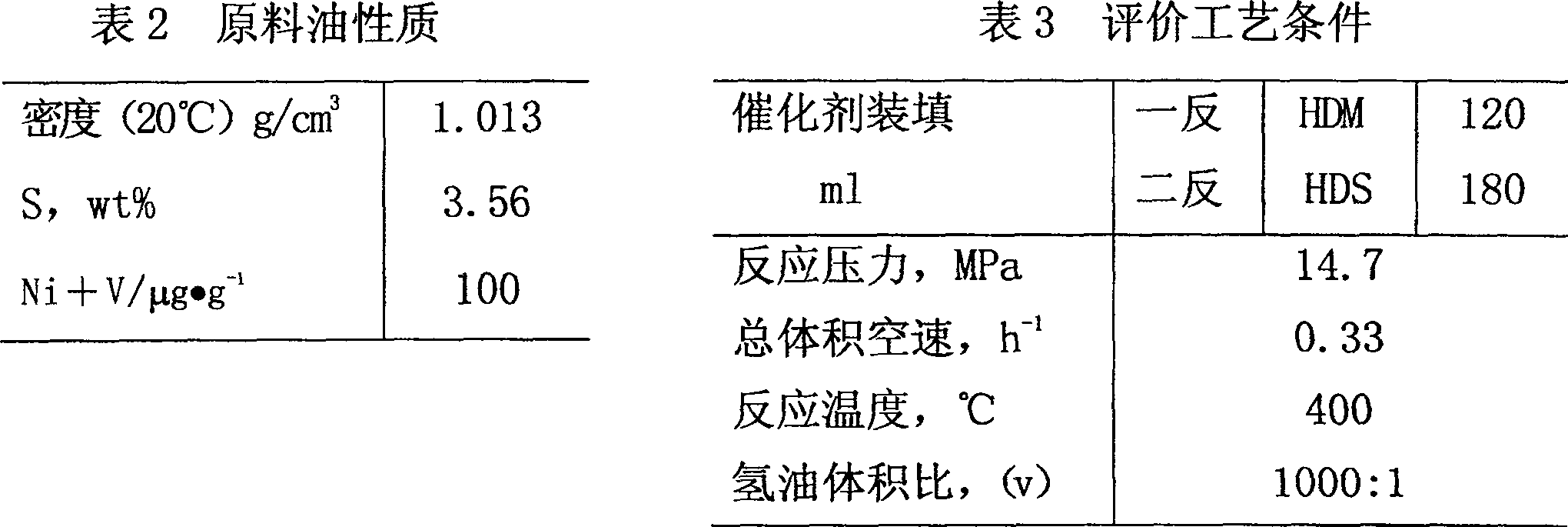

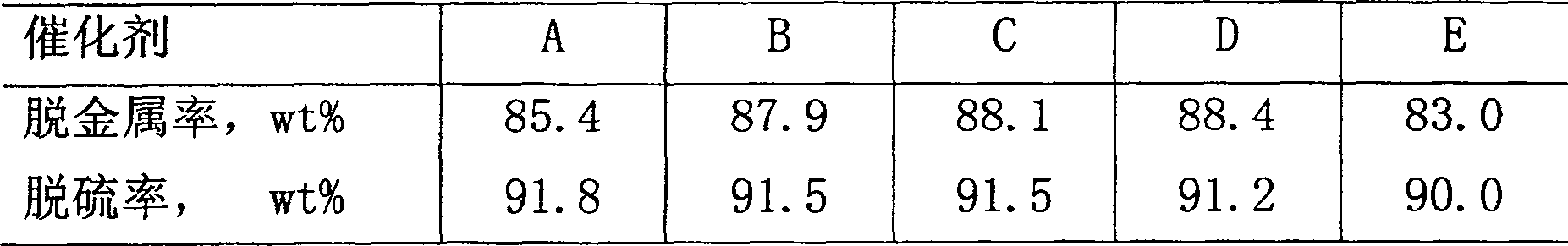

Embodiment 1

[0025] The preparation concentration is 30gAl 2 o 3 / l, sodium metaaluminate solution with an atomic ratio of Na to Al of 1.4. Take a certain amount of sodium metaaluminate solution and put it in the gelling kettle, adjust the pH value to 14, and the temperature is 25°C, start to feed carbon dioxide gas with a concentration of 40v%, and add the pH value while stirring the carbon dioxide gas For the titanium trichloride solution of 2, when the pH value becomes 6.5, add sodium metaaluminate solution to make the pH value become 10.5, and stir for 5-10 minutes; repeat the above steps once, and then when the pH value of the slurry is 10.5 When the carbon dioxide gas is stopped. The slurry was aged for 1.0 hour. Filter and wash with deionized water until the aluminum hydroxide contains Na + When 3 The concentration is 30.0wt%, the solution contains NH 3 It is 10wt%, fully mixes to alkaline solution and aluminum hydroxide powder is wetted, then adds 36g acidic solution, contains ...

Embodiment 2

[0027] Compared with Example 1, the atomic ratio of Na to Al in the sodium metaaluminate solution was changed to 1.6, and the amount of other materials and operating conditions were the same as in Example 1, namely the product B of this example.

Embodiment 3

[0029] Compared with Example 1, the process of changing the pH value of the sodium metaaluminate solution from 14 to 6.5 and then to 10.5 was repeated 3 times, and the amount of other materials and operating conditions were the same as in Example 1, namely product C of this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com