Electronic sensing type electric pressure cooker

An electric pressure cooker and sensing technology, applied in pressure cookers and other directions, can solve the problems affecting the safety and reliability of the electric pressure cooker, the pressure adjustment deviates from the set value, and the control accuracy is not high, and achieves simple structure, reliable performance, and control range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

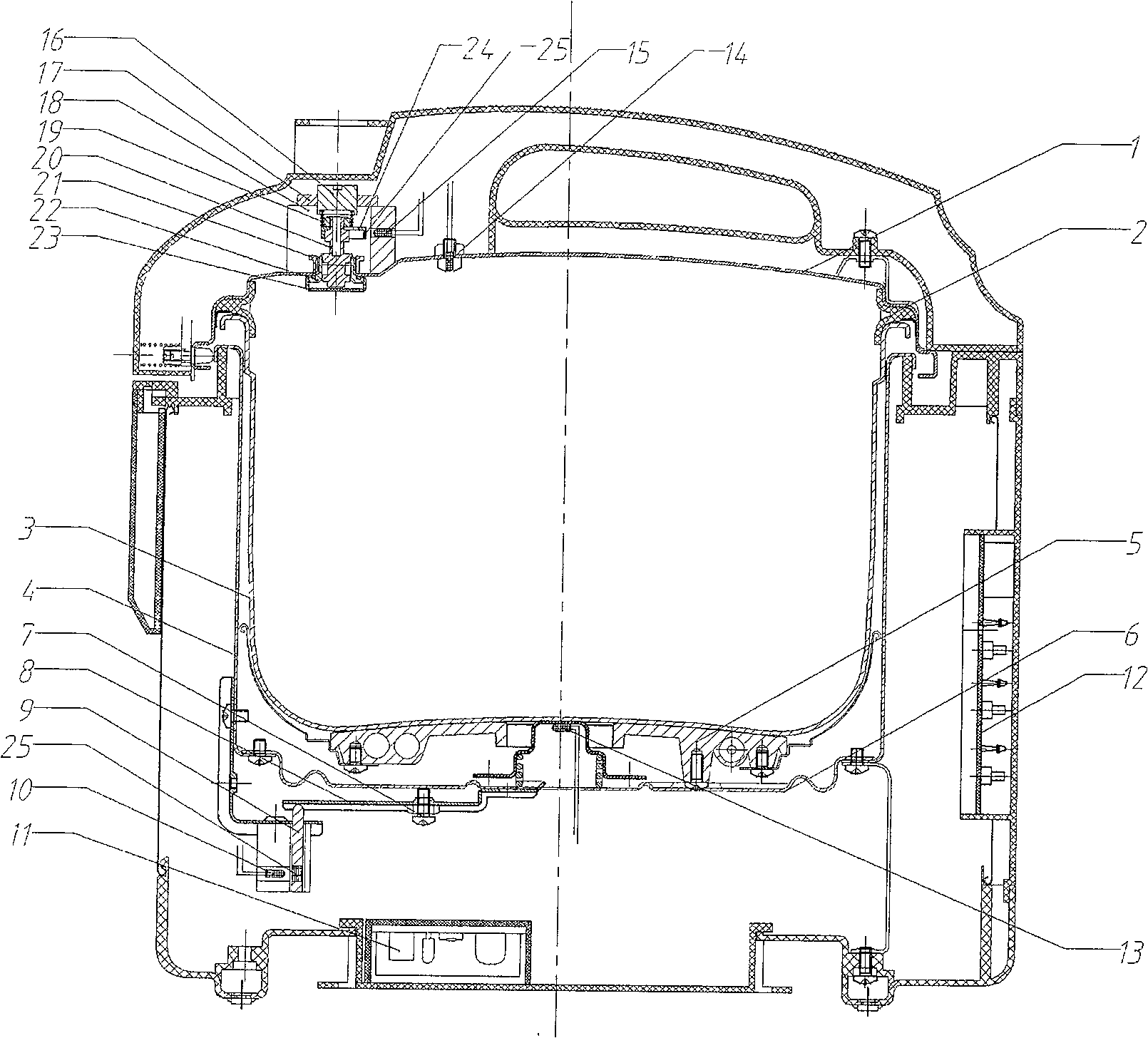

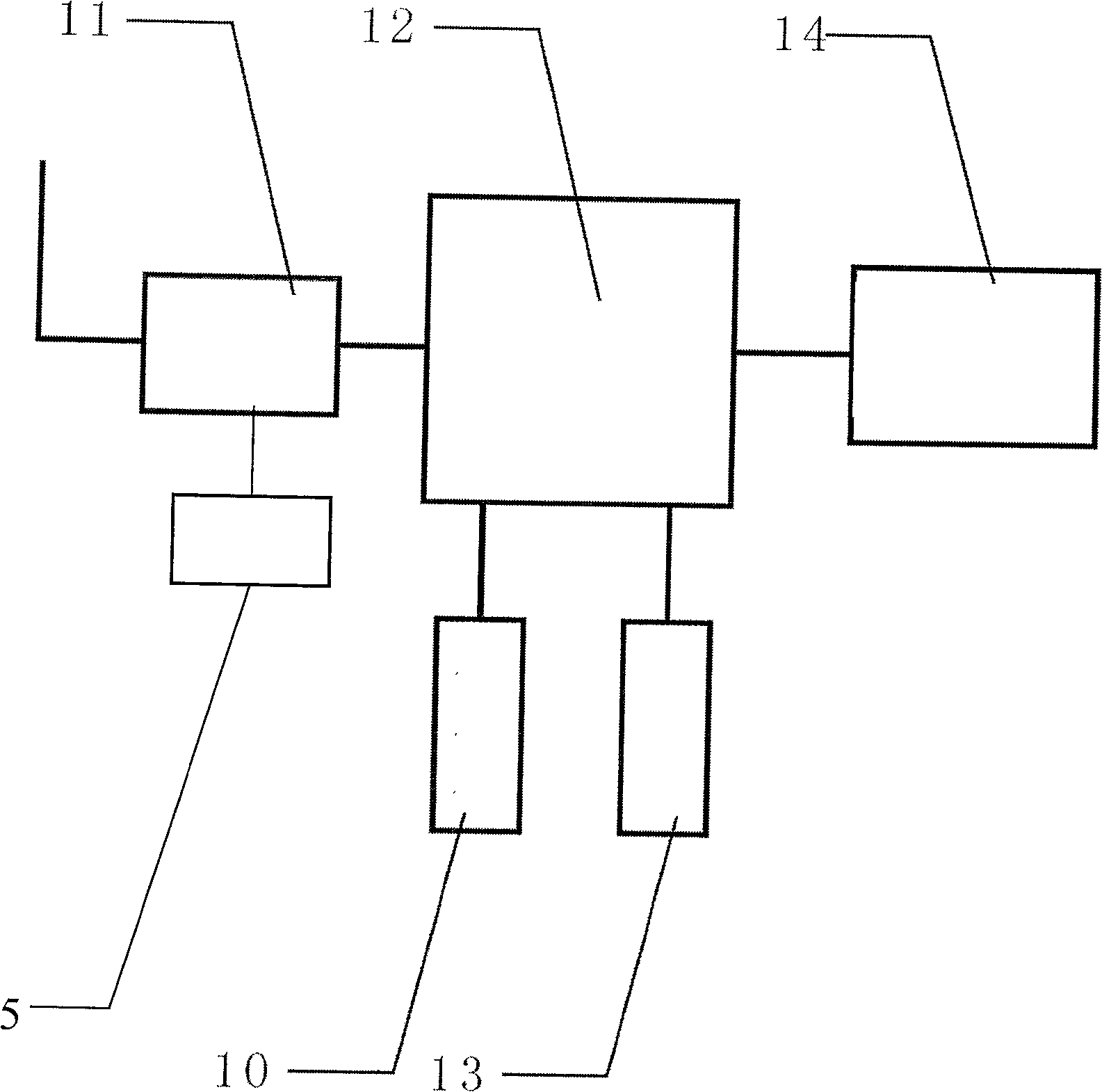

[0023] The induction source assembly and the sensor 10 are arranged at the bottom of the inner pot 3 . The induction source assembly is composed of a moving part 9 attached with a magnetic source or light source 25 , the moving part 9 is connected with the elastic ring 6 through the adjusting piece 8 and moves up and down with the deformation of the elastic ring 6 . The sensor 10 is a stroke sensor, which is located on one side of the induction source assembly. The control chip 12 can adopt the S3F9454 chip produced by South Korea's Samsung Electronics.

[0024] When the pressure inside the pot increases, the pot inner 3 presses down on the elastic ring 6 to make it deform, thereby driving the moving part 9 to move down to the set position, reaching the sensing distance of the sensor 10, and the sensor 10 can sense the light at this time Or magnetically, an induction signal is sent to the control chip 12, and the control chip 12 sends an instruction to cut off the power suppl...

Embodiment 2

[0028] In the conjoined pot cover structure, the induction source assembly and the sensor 15 can be arranged inside the pot cover 1 . The induction source assembly is composed of a moving part 24 with a magnetic source or a light source 25 attached, and the moving part 24 is connected and linked with the pressure valve of the pot cover 1 . The pressure valve includes a pressure regulating screw 16, a locking nut 17, a sensor bracket 18, a pressure regulating spring 19, a valve core 20, a valve cap 21, a valve seat 22 and a rubber sleeve 23 and the like. The moving part 24 is arranged on the valve core 20 and moves up and down with the valve core. The valve core 20 and the moving part 24 can be made integrally or separately.

[0029] The pressure regulating screw 16 is used to adjust the working pressure value of the pressure regulating spring 19. When the pressure in the pot rises, the valve core 20 is pushed up by the soft rubber sleeve 23 to move upward, so that the moving ...

Embodiment 3

[0032] In order to further improve safety, the automatic pressure control mechanism includes two sets of induction source components and inductors, which are respectively arranged at the bottom of the pot liner 3 (as in embodiment 1) and inside the pot cover 1 (as in embodiment 2).

[0033] Similarly, a bottom temperature sensor 13 is also provided at the bottom of the pressure cooker pot 3 , and a pot cover temperature sensor 14 is provided on the pot cover 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com