Air cushion driver for air float displacement table

A technology of displacement stage and air cushion, applied in the directions of transportation and packaging, instrument parts, instruments, etc., can solve the problems of high cost, poor motion sensitivity, affecting the motion accuracy of the worktable, etc., and achieve the effect of low cost and high motion sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

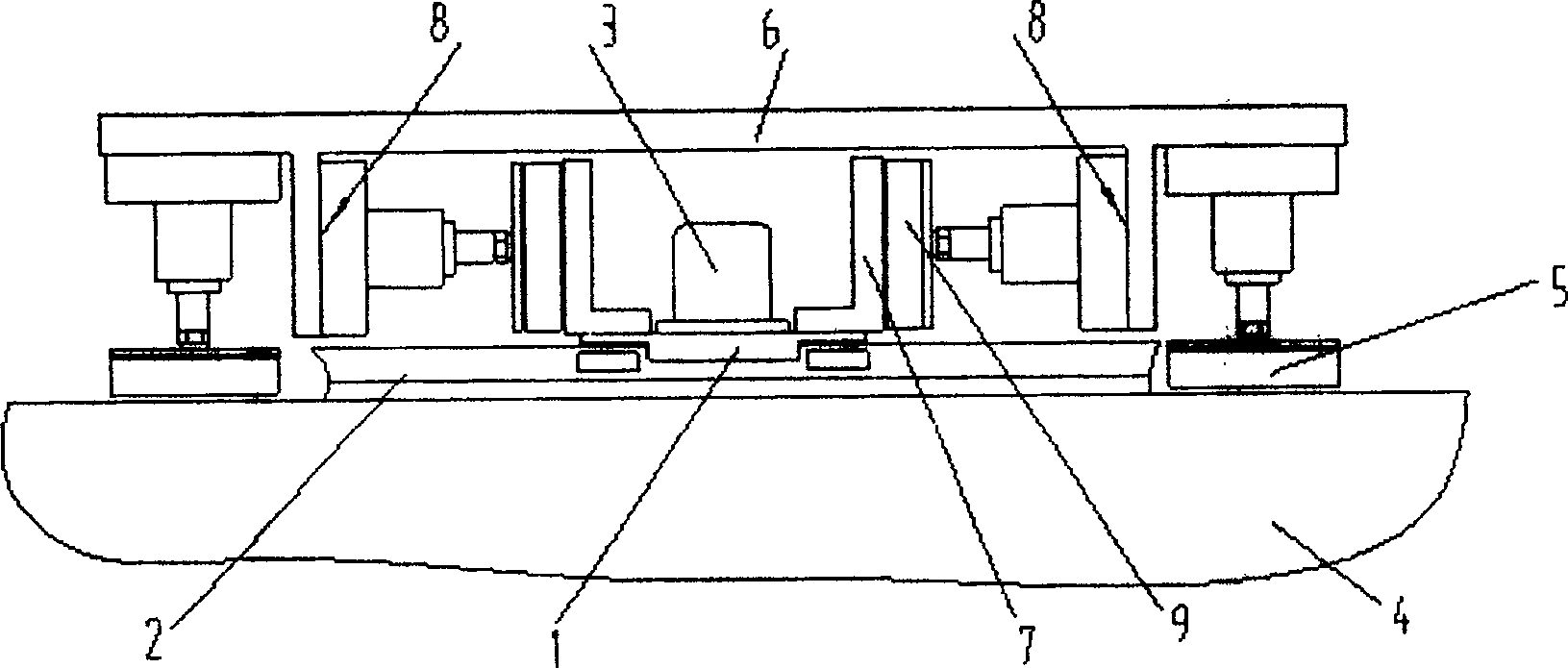

[0014] The present invention will be described in further detail below. see figure 1 , the air cushion driving device of the present invention includes a transmission mechanism composed of a trolley 1, a metal guide rail 2 and a trolley drive mechanism, the metal guide rail 2 is installed on the granite guide rail 4, and there is a moving work supported on the granite guide rail 4 by an air cushion 5 Platform 6, said trolley drive mechanism is one of the following structures:

[0015] a. It consists of a drive motor 3 fixed on the trolley 1. figure 1 The embodiment shown is such a structure.

[0016] b. It consists of a nut fixed on the trolley 1 and a lead screw fixed on the granite guide rail 4.

[0017] c. It is composed of the bearing fixed on the trolley 1 and the light rod fixed on the granite guide rail 4.

[0018] d. It is composed of steel belt or wire rope transmission mechanism.

[0019] The above trolley driving mechanisms are all known technologies, and will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com