Hoisting and transporting winch

A winch and output shaft technology, applied in hoisting devices, clockwork mechanisms, etc., can solve problems such as limiting the use range of winches, resistors are difficult to implement explosion-proof requirements, slip ring motors cannot meet explosion-proof requirements, etc., and achieve outstanding essence The effect of sexuality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

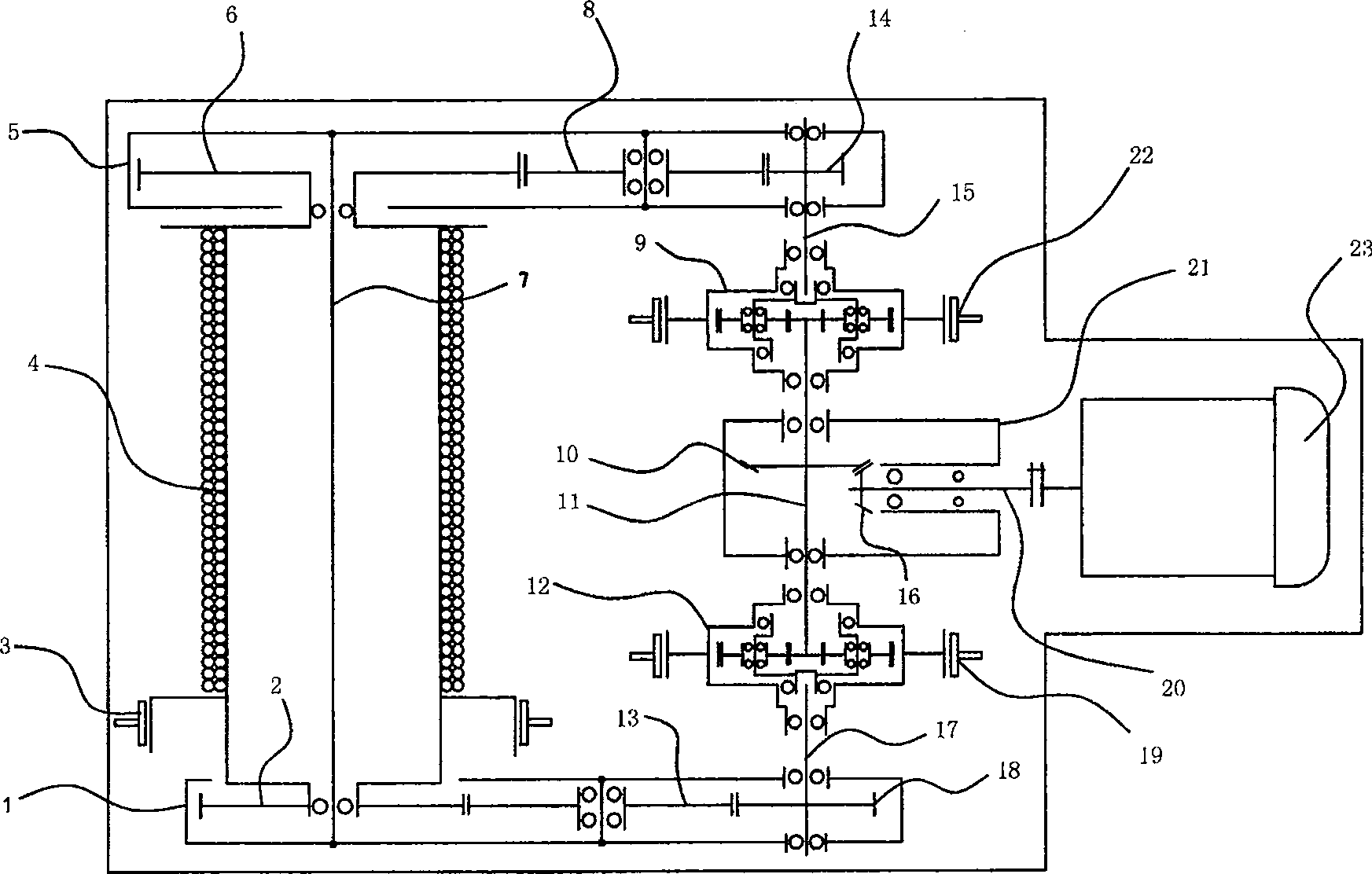

[0008] In order to clearly illustrate the technical characteristics of this solution, the following describes this solution through a specific implementation and in conjunction with the accompanying drawings.

[0009] It can be seen from the drawings that the lifting and transportation winch of this scheme has a squirrel-cage motor 23 and a reduction box 21 driven by the motor 23. One end of the reduction box output shaft 11 of the reduction box 21 is connected to the input of the slow planetary gear box 9 Shaft, the other end is connected to the input shaft of the fast planetary gearbox 12, the output shaft of the slow planetary gearbox 9 is connected to the slow gearbox input shaft 15 of the slow gearbox 5, and the output shaft of the fast planetary gearbox 12 is connected to the fast gearbox 1 fast gearbox input shaft 17, slow gearbox 5 slow gearbox output gear 6 and fast gearbox 1 fast gearbox output gear 2 at the same time connected to the drum 4, the drum 4 is positioned by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com