Method for preparing universal pitch charcoal fibre

A kind of pitch carbon, general-purpose technology, applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of high cost, complicated process, high equipment requirements, etc., and achieve high residual carbon value, simple preparation process and small discreteness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

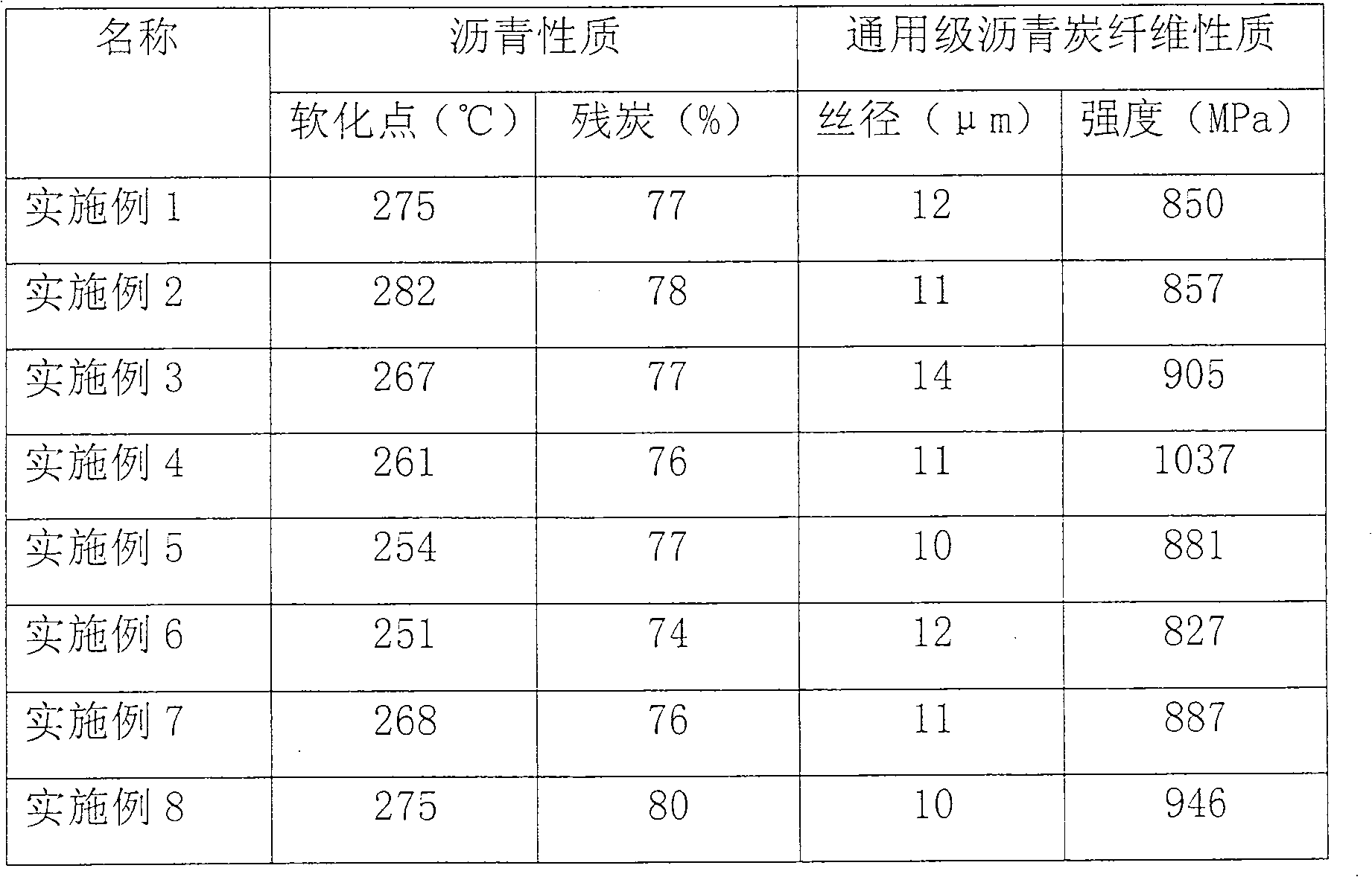

[0015] Put ethylene tar with 7% carbon residue and 0.03% ash into the reactor, let air in and stir at the same time, the ratio of the mass of ethylene tar to the air flow is 2000g: 0.4m 3 / h, according to the heating rate of 1.5 °C / min, the temperature was raised to 330 °C, and the temperature was kept at this temperature for 1 hour, and then the temperature was raised to 360 °C under the protection of nitrogen, and the temperature was kept at this temperature for 4 hours. General-purpose pitch carbon fibers were prepared by melt spinning, non-melting, and carbonization. The melt spinning temperature above is 330°C and the pressure is 0.3 MPa; the final non-melting temperature is 290°C, and the non-melting time is 8 hours; the carbonization temperature is 900°C and the heating rate is 1°C / min. The properties of the raw material pitch and carbon fiber are shown in Table 1.

Embodiment 2

[0017] Put ethylene tar with 8% carbon residue and 0.04% ash into the reaction kettle, feed air and stir at the same time, the ratio of the mass of ethylene tar to the air flow rate is 1900g: 0.3m 3 / h, according to the heating rate of 1.0 °C / min, the temperature is raised to 320 °C, and the temperature is kept at this temperature for 3 hours. Then the temperature was raised to 370° C. under the protection of nitrogen, and kept at this temperature for 3 hours. General-purpose pitch carbon fibers were prepared by melt spinning, non-melting, and carbonization. The melt spinning temperature above is 360°C and the pressure is 0.5MPa; the final non-melting temperature is 300°C, and the non-melting time is 7 hours; the carbonization temperature is 1000°C and the heating rate is 2°C / min. The properties of the raw material pitch and carbon fiber are shown in Table 1.

Embodiment 3

[0019] Put ethylene tar with 10% carbon residue and 0.01% ash into the reactor, let air in, and stir from time to time. The ratio of the mass of ethylene tar to the air flow is 1800g: 0.2m 3 / h, according to the heating rate of 0.5 ° C / min to 260 ° C, at this temperature for 7 hours. Then the temperature was raised to 380° C. under the protection of nitrogen, and kept at this temperature for 0.5 hours. General-purpose pitch carbon fibers were prepared by melt spinning, non-melting, and carbonization. The melt spinning temperature above is 325°C and the pressure is 0.8 MPa; the final non-melting temperature is 280°C, and the non-melting time is 11 hours; the carbonization temperature is 1200°C and the heating rate is 3°C / min. The properties of the raw material pitch and carbon fiber are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com