Carbon steel protectant for open-circuit water softening system and preparation method and application thereof

A protective agent and water softening technology, which is applied in the field of industrial water treatment, can solve problems such as material damage, and achieve the effects of improved peeling, good corrosion inhibition performance, and good chlorine oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

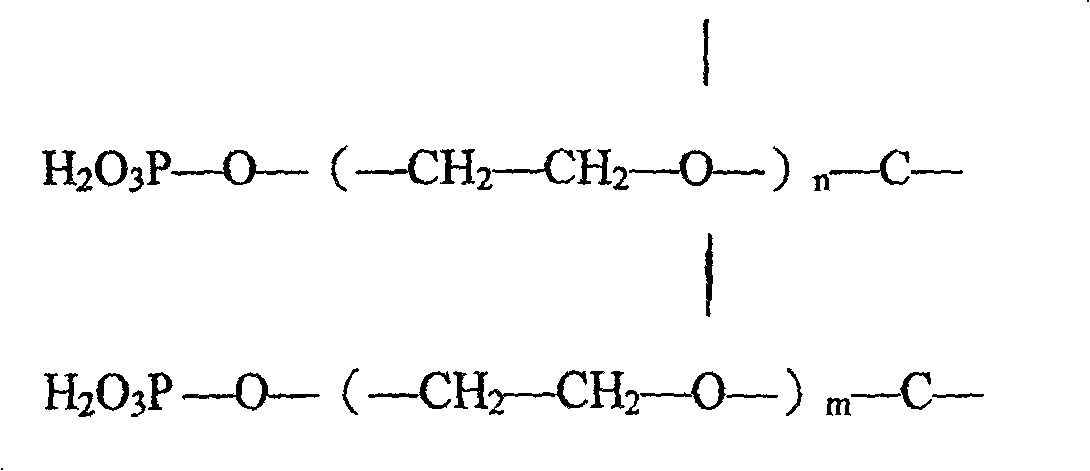

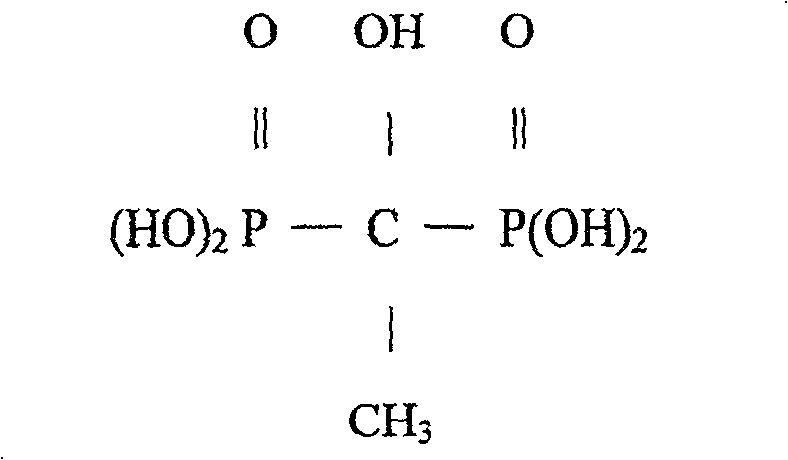

[0058] Copper pipe protector (TWZL-001) for open circuit softening water system, containing the following components (kg): 25 parts of glycine dimethylphosphonic acid, 5 parts of polyol phosphate, 5 parts of hydroxyethylidene diphosphonic acid , 15 parts of high molecular polymer zinc salt and 50 parts of water.

[0059] The preparation method of this carbon steel protective agent is:

[0060] 1. Raw material preparation: According to the above-mentioned formula ratio, weigh glycine dimethylene phosphonic acid, polyol phosphate, hydroxyethylene diphosphonic acid and polymer zinc salt in sequence with a metering pump.

[0061] 2. Production: Turn on the vacuum pump, and glycine dimethylphosphonic acid, polyol phosphate, and hydroxyethylene diphosphonic acid will be pumped into the reaction kettle. When the reaction temperature is 40-50°C, the stirring speed is 80 rpm Stir for 20 minutes under certain conditions; after that, add water and stir, then add high-molecular polymer z...

Embodiment 2

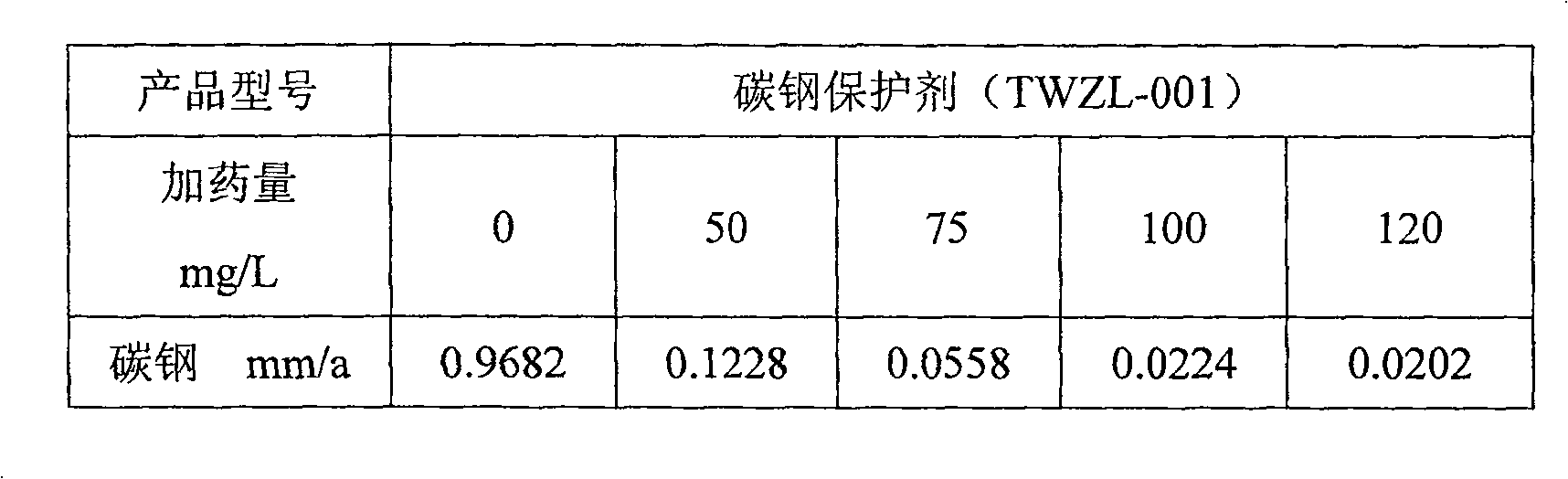

[0063] Corrosion inhibition experiment of the corrosion inhibitor (TWZL-001) of the present invention on carbon steel.

[0064] 2.1 Purpose of the experiment.

[0065] The method of rotating coupon corrosion test is to evaluate the corrosion inhibition performance of water treatment agent by calculating the corrosion rate and corrosion inhibition rate by using the loss mass of the test piece under the given conditions in the laboratory. The corrosion characteristics of the open-circuit demineralized water system are investigated by using the rotating coupon corrosion measurement method, and the corrosion inhibition performance of the product of the present invention is comprehensively evaluated by indicators such as the appearance color change of the carbon steel after the test, and the corrosion rate measured by the weight loss method.

[0066] 2.2 Experimental conditions.

[0067] Experimental water quality: The experimental water is provided by a continuous casting net rin...

Embodiment 3

[0093] The comparative experiment of the corrosion inhibition performance of the composition of the present invention, that is, the carbon steel protective agent and other corrosion inhibitors.

[0094] 3.1 Purpose of the experiment.

[0095] Carry out the carbon steel corrosion inhibition test for different corrosion inhibitors, still utilize the rotating coupon corrosion measurement method, adopt the same soft water system, and judge the corrosion inhibition performance of the present invention by comparison.

[0096] 3.2 Experimental conditions and experimental procedures.

[0097] Same as 2.2 and 2.3.

[0098] 3.3 Experimental conclusion.

[0099] The following table is the test results of the present invention and other similar corrosion inhibitors on carbon steel surface.

[0100] Table 4 Comparison of carbon steel corrosion rates under different corrosion inhibitors. Scale and corrosion inhibitor B is a composition of different important components

[0101]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com