Frame combination of back light module and backlight module using said frame

A backlight module, combined structure technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of uneven display brightness, time-consuming and laborious, and damage to frame components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings.

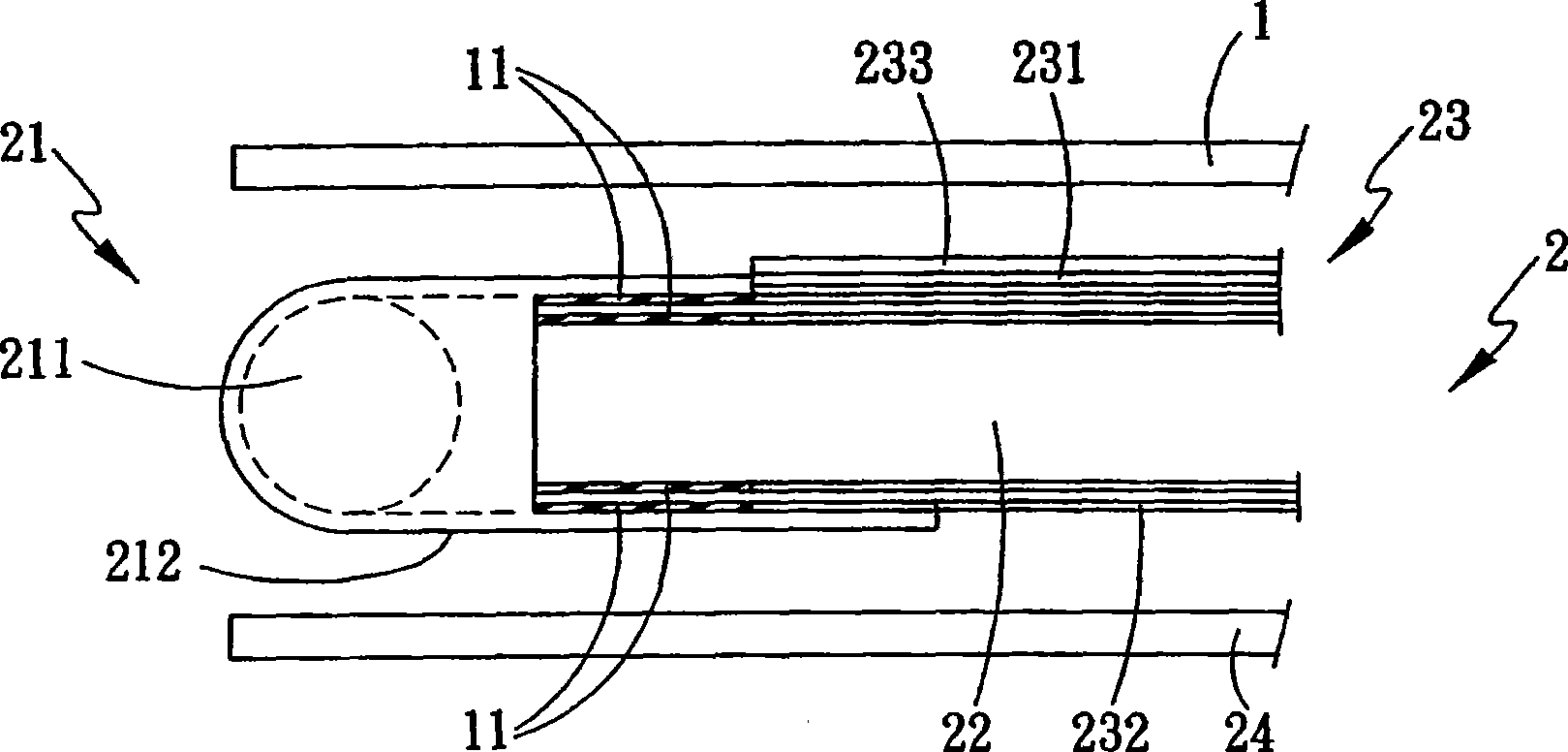

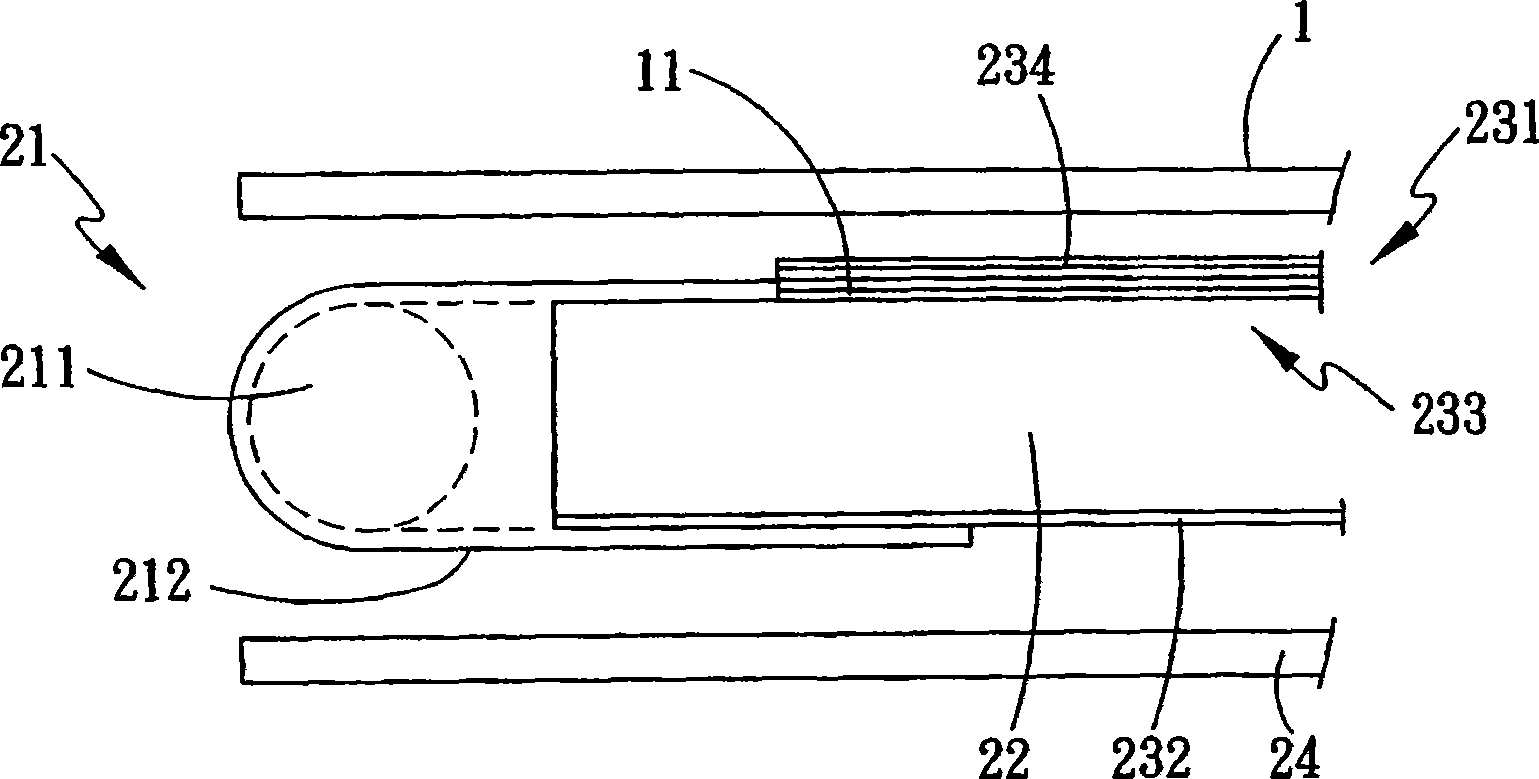

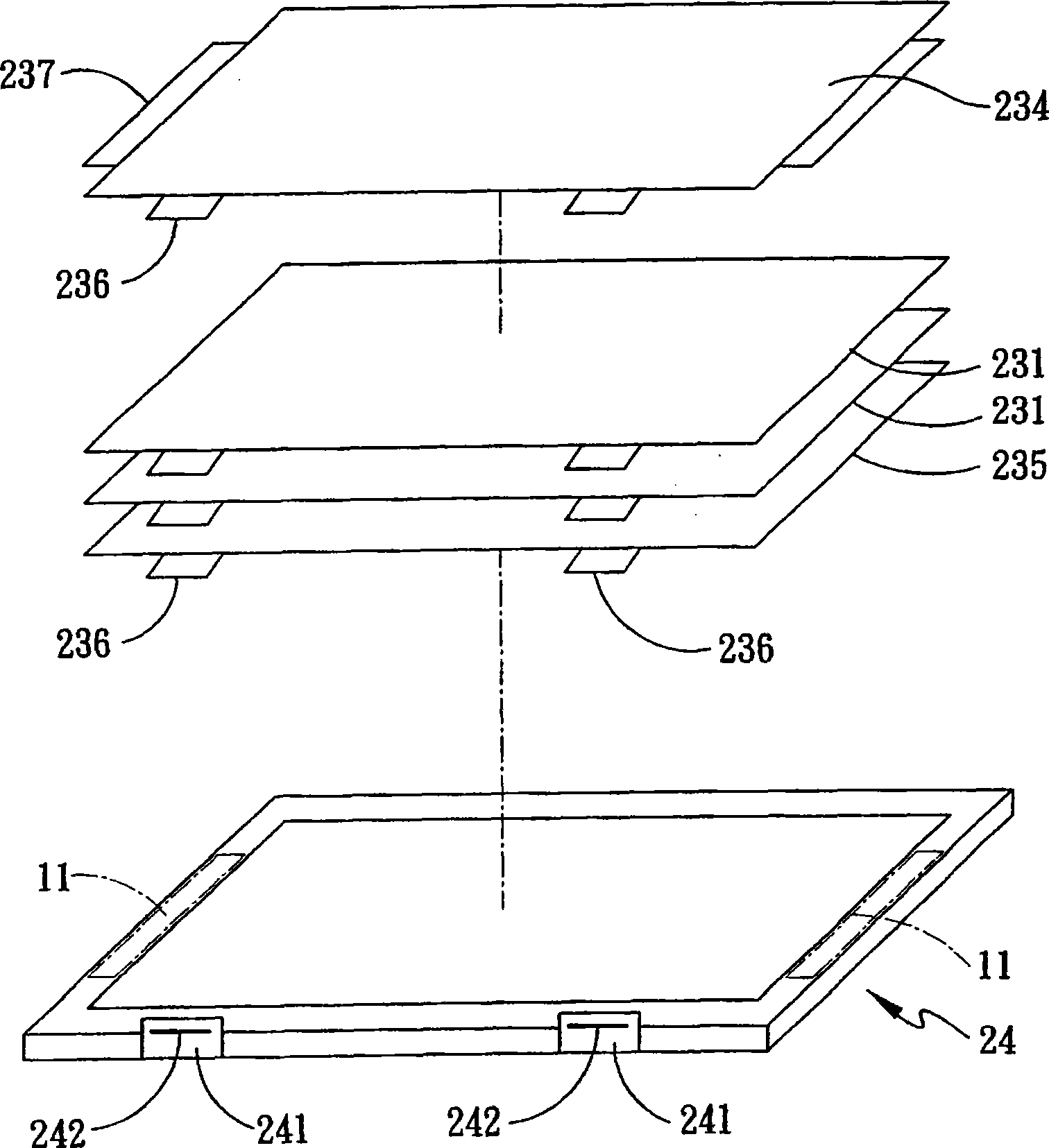

[0042] refer to Figure 5 to Figure 7 , the preferred embodiment of the liquid crystal display backlight module of the present invention includes a frame 4 , an optical film set 5 , two cover plates 421 , and two locking devices 42 . Wherein, the optical film group 5 is a prism film 231 (see figure 2 ), a reflective film 232 (see figure 2 ) and a diffusion film 233 (see figure 2 ), and the frame 4 has a left surface 411 and a right surface 412.

[0043] In this embodiment, the frame 4 forms a pair of cover plates 421 respectively corresponding to the left and right surfaces 411, 412 during injection molding. The structures of the two cover plates 421 are symmetrical and one end of each cover plate 421 is A connecting portion 425 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com