Pumping rod centralizer retainer ring assembling machine

A technology for centralizers and sucker rods, which is applied in the field of assembling machines for sucker rod centralizer retaining rings, can solve the problems of many processes, high technical difficulty, damage and deformation of sucker rods, etc., and achieve simple mechanical equipment and low technical difficulty , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

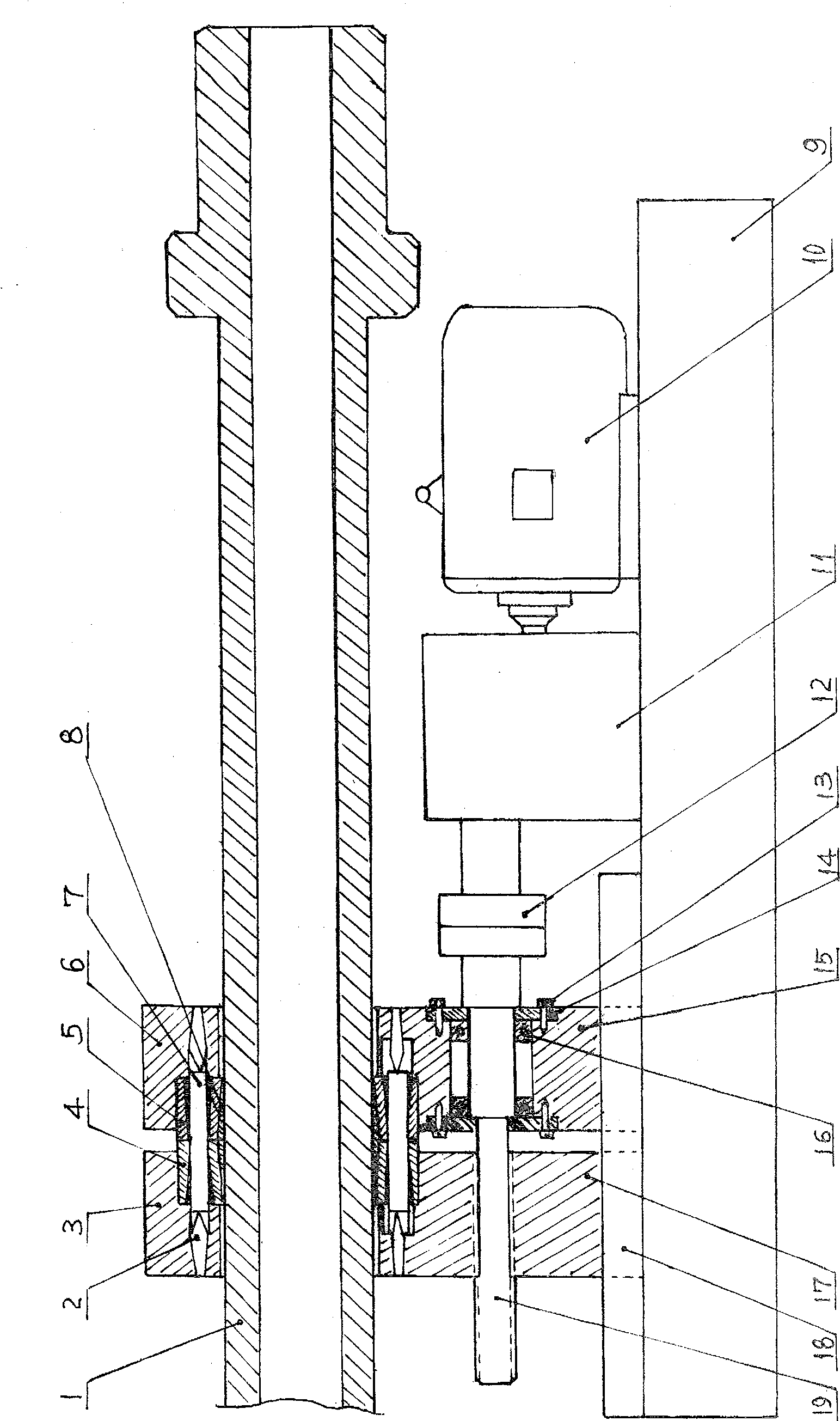

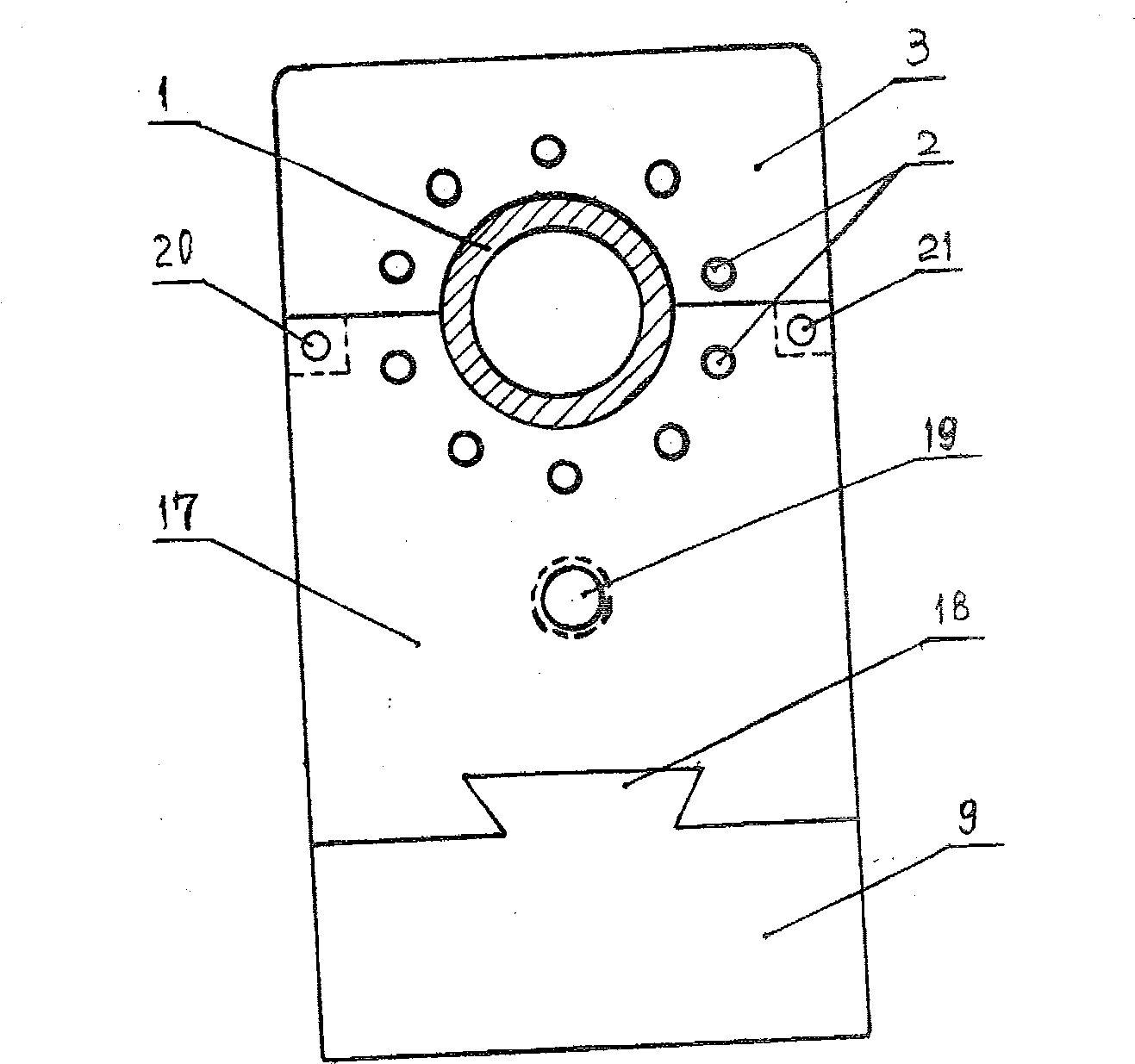

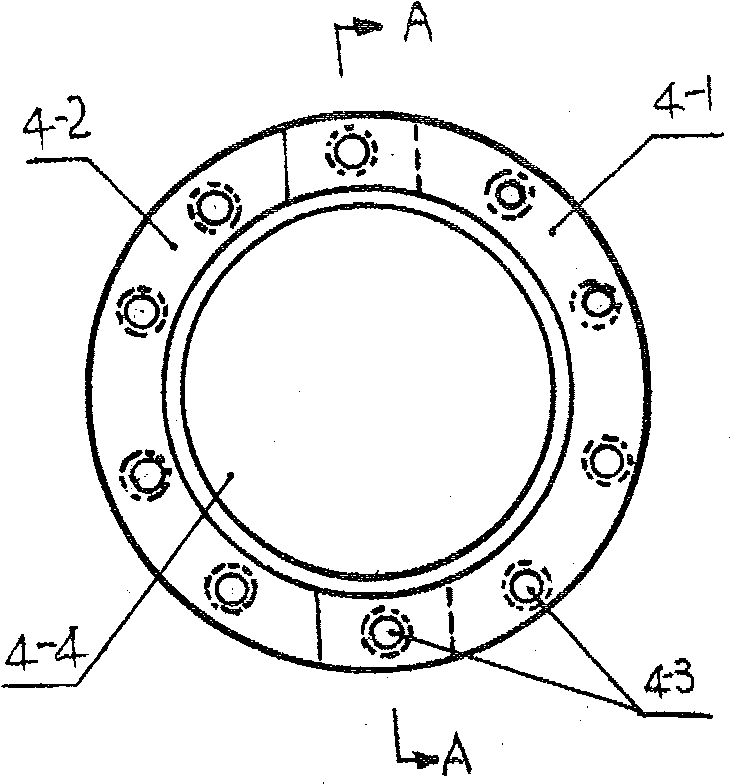

[0012] Referring to the accompanying drawings, a sucker rod centralizer retaining ring assembly machine is composed of a motor 10, a reducer 11, a coupling 12 and a frame 9, and its characteristic is that a screw 19 is fixed on the left side of the coupling 12 , the right section of the lead screw 19 is movably installed in the thrust bearing 16, the thrust bearing 16 is fixed on the fixed clamping plate base 15 with the bearing retaining ring 14 and the bolt 13, and the bottom of the fixed clamping plate base 15 is provided with a dovetail groove and a machine base The dovetail guide rails 18 provided on the 9 are assembled together, five tops 2 are fixed on the fixed clamping plate base 15, the upper left corner of the fixed clamping plate base 15 is connected with a fixed pin shaft 20, and the upper right corner is connected with a movable pin 21 Tightening plate cover 6, five tops 2 are fixed on the fixed clamping plate cover 6; the left section of the screw 19 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com