Hybrid driving type wind motor increasing gear case

A wind turbine, hybrid drive technology, applied in the direction of wind turbine components, wind turbines, transmission boxes, etc., to reduce the overall failure rate, compact structure, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

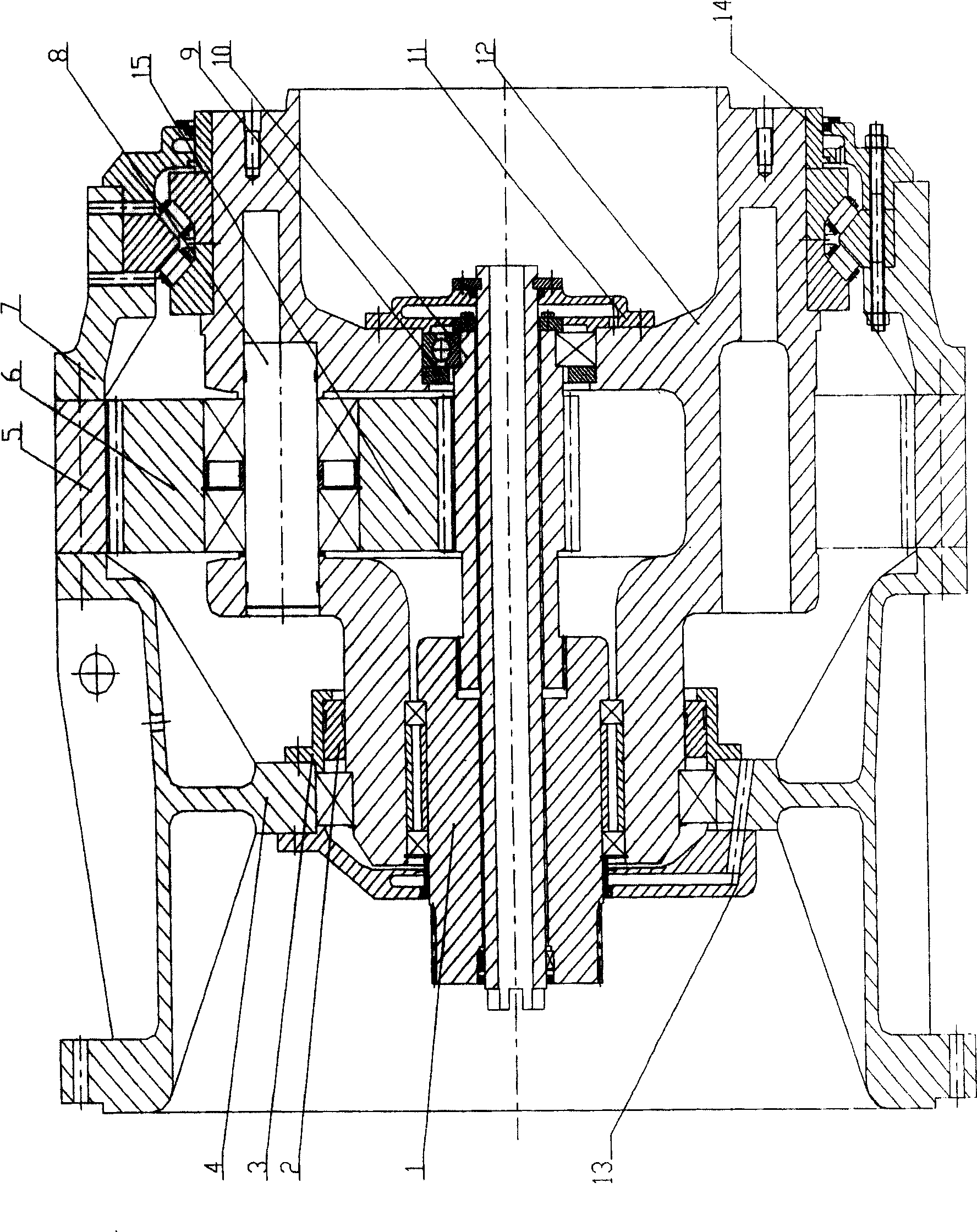

[0015] The accompanying drawings non-limitingly disclose a schematic structural diagram of a specific embodiment of the present invention. The present invention will be further described below in conjunction with the accompanying drawings.

[0016] by figure 1 It can be seen that the inner gear ring 5 is arranged between the front box body 7 and the rear box body 4, which are connected by bolts in turn. The rear box body 4 is equipped with a rear cover 13; the input planet carrier 12 and the sun gear directly docked with the hub 15 coaxial, the front end of the input planet carrier 12 is installed on the front box 7 through a double-row tapered roller bearing, the rear end of the input planet carrier 12 is installed on the rear box 4 through the bearing, and the input end passes through the front Box 7; three planetary gears 6 are evenly arranged around the input planet carrier 12, and the planetary gears 6 mesh with the ring gear 5 and the sun gear 15 at the same time; one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com