Repair-reporting control method for resumable linear temperature-sensing detector

A technology of temperature-sensitive detectors and control methods, which is applied to thermometers, thermometer testing/calibration, and instruments using directly heat-sensitive electric/magnetic elements, and can solve problems such as reducing the reliability of detector alarms and false alarms , to achieve the effect of improving the reliability of the alarm and eliminating the problem of false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

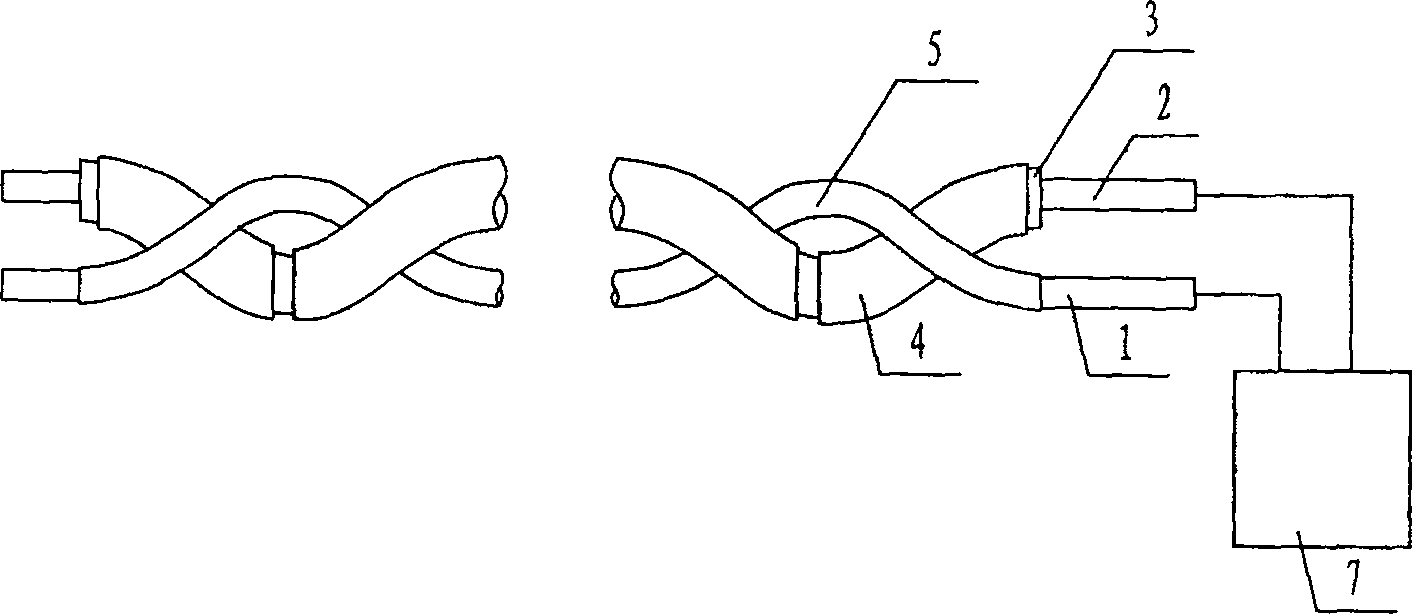

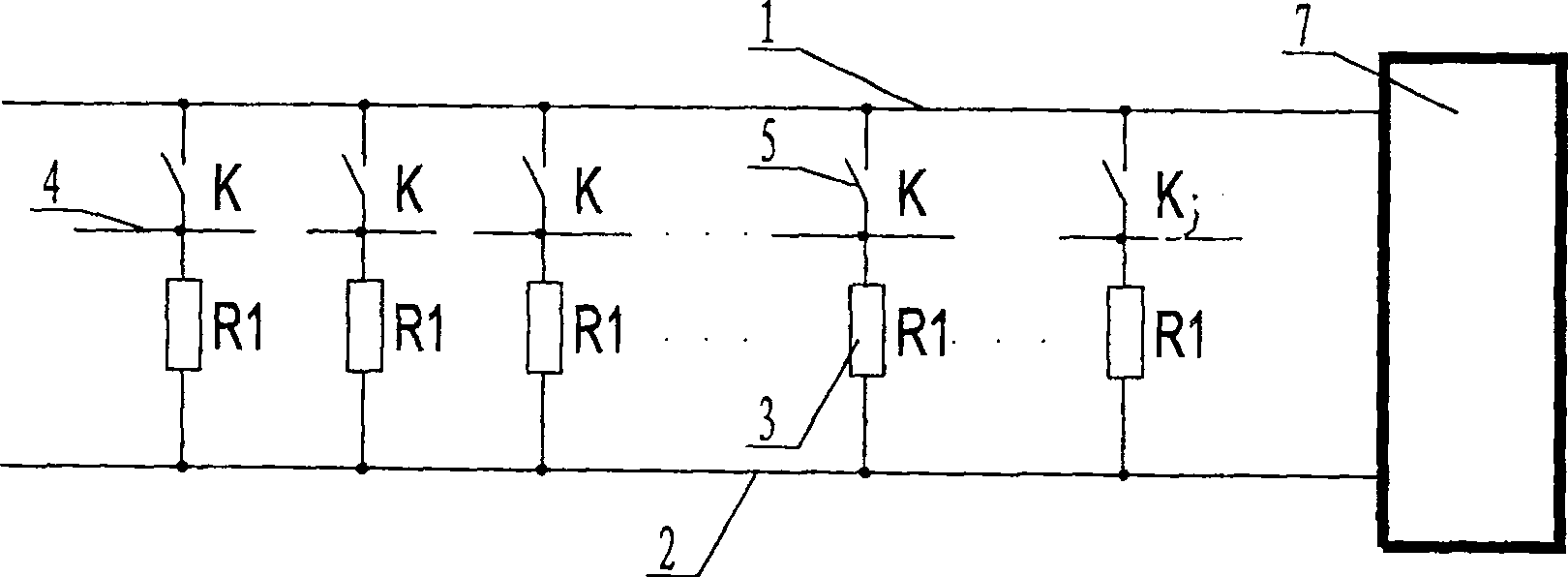

[0027] The repair control method for the recoverable linear temperature-sensitive detector provided by the present invention is applicable to figure 1 Shown is a recoverable linear heat detector. The recoverable linear temperature sensing detector is composed of a linear temperature sensing element and a conversion box 7 connected to one end of the linear temperature sensing element; wherein the linear temperature sensing element includes two parallel detection conductors 1, 2 and An NTC or CTR characteristic material layer 3, a discontinuous conductive layer 4 and a meltable insulating layer 5 are arranged in parallel between two detection conductors 1, 2, wherein two detection conductors 1, 2 can be used in parallel, Winding or coaxial arrangement, and at least one of them is an elastic conductor, the value corresponding to the sampling value detected by the conversion box 7 to the linear temperature sensing element is the resistance value R.

[0028] At least one of the tw...

Embodiment 2

[0036] The recoverable linear temperature-sensitive detector in this embodiment has the same structure as the recoverable linear temperature-sensitive detector in Embodiment 1.

[0037] In order to more reliably determine whether the cumulative length LJ of the contact conduction area on the recoverable linear heat detector exceeds the maximum contact conduction length Lmax, the method for the recoverable linear heat detector provided in this embodiment The call control method includes the following steps in sequence:

[0038] 1) Input a functional relationship LJ=f(T0, R) or LJ=f(T0, U) in the conversion box 7 in advance, and input a maximum contact conduction length Lmax (or its corresponding sampling value) that meets the requirements of the national standard Or the stage of the resistance value R or the voltage value U) corresponding to the sampling value;

[0039] 2) Under manual or automatic conditions, the conversion box 7 detects the ambient temperatures T1 and T2 of ...

Embodiment 3

[0045] The recoverable linear temperature-sensitive detector in this embodiment has the same structure as the recoverable linear temperature-sensitive detector in Embodiment 1.

[0046] In order to more reliably determine whether the cumulative length LJ of the contact conduction area on the recoverable linear heat detector exceeds the maximum contact conduction length Lmax, the method for the recoverable linear heat detector provided in this embodiment The call control method includes the following steps in sequence:

[0047] 1) Input a functional relationship LJ=f(T0, R) or LJ=f(T0, U) in the conversion box 7 in advance, and input a maximum contact conduction length Lmax (or its corresponding sampling value) that meets the requirements of the national standard Or the stage of the resistance value R or the voltage value U) corresponding to the sampling value;

[0048] 2) Under manual or automatic conditions, the conversion box 7 detects at least two different ambient tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com