Explosion-proof steel cylinder with pretensioning conductive wire and method for setting the same

A technology of conductive wire and steel cylinder, which is applied in the container discharge method, container filling method, mechanical equipment and other directions, can solve the problems of difficult processing of conductive wire, poor explosion alarm time, large brittleness, etc., and achieves a simple and easy setting method and reliable alarm. High performance and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The explosion-proof steel cylinder with pretensioned conductive wire and the method for setting the conductive wire provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Components that are the same as those in the prior art are assigned the same reference numerals, and their descriptions are omitted.

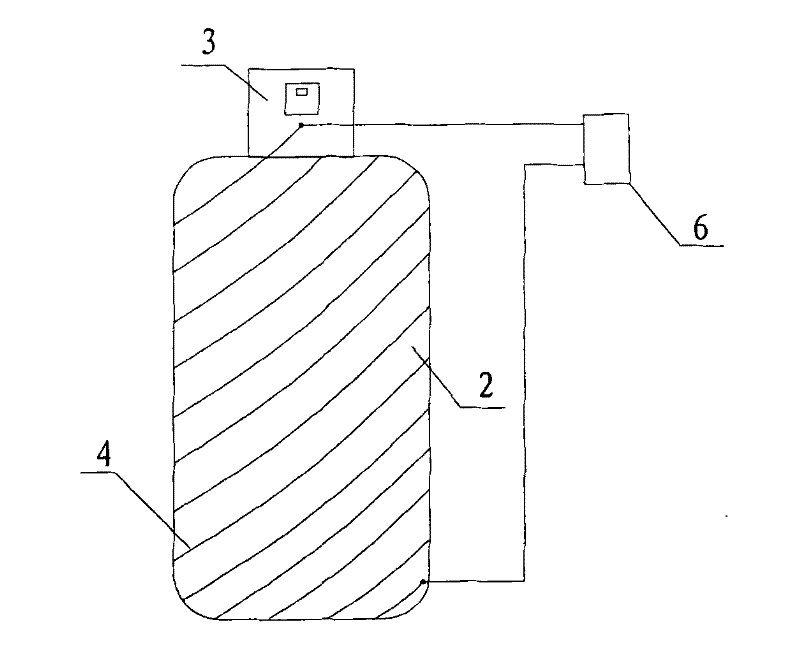

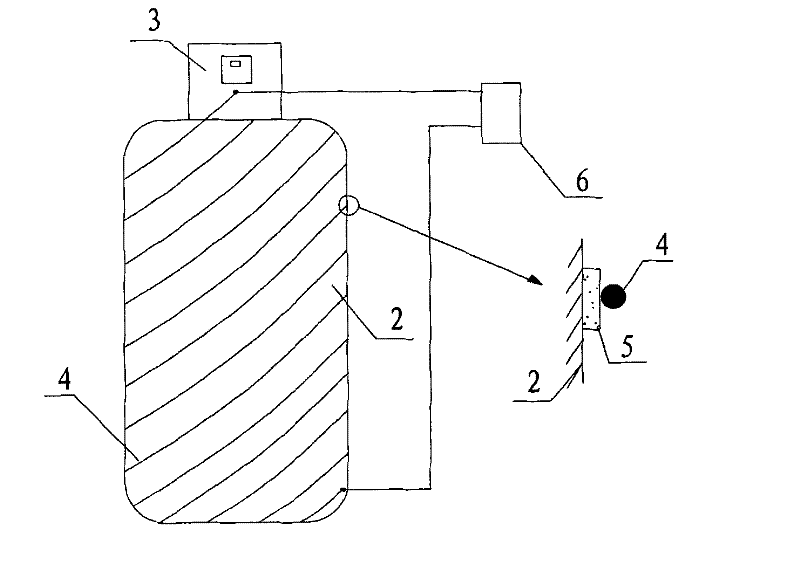

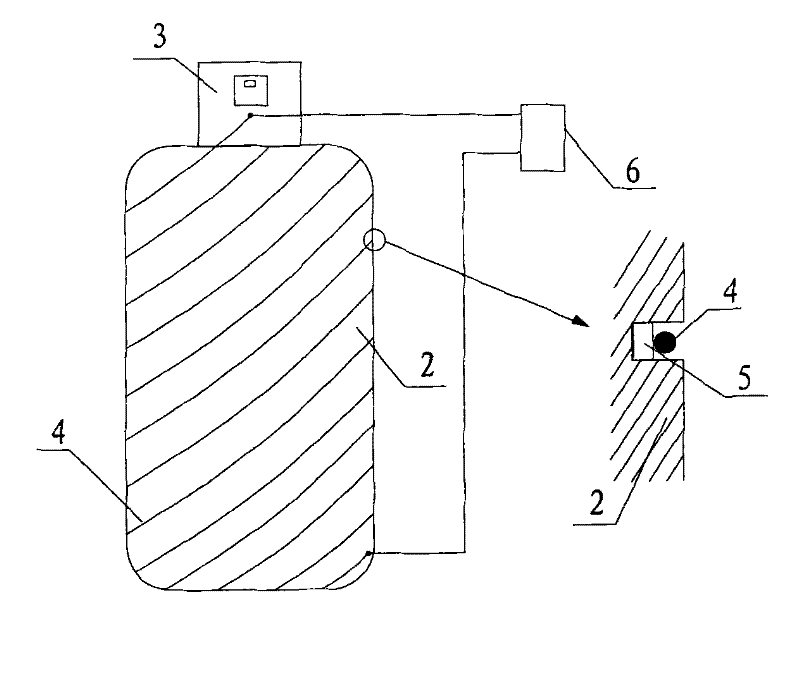

[0019] Such as figure 2 , image 3 As shown, the explosion-proof steel cylinder provided by the present invention has a pretensioned conductive wire mainly composed of a steel cylinder 2, which is installed on the upper opening of the steel cylinder 2, and is used to seal the fire extinguishing agent stored in the steel cylinder 2 or the container valve of the driving gas. 3. The conductive wire 4 wound on the outer wall of the steel cylinder 2 in a spiral manner at intervals and connected to the measuring end of the conductive wire 4 is composed of an alarm box 6 for monitoring the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com