Automotive engine hood

A technology for engine hoods and motor vehicles, which is applied to vehicle parts, upper structures, upper structure sub-assemblies, etc., which can solve the problems of increased elastic deformation of the outer panel 122 and inability to ensure the tension and rigidity of the engine hood, and achieve excellent protection performance , HIC value reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

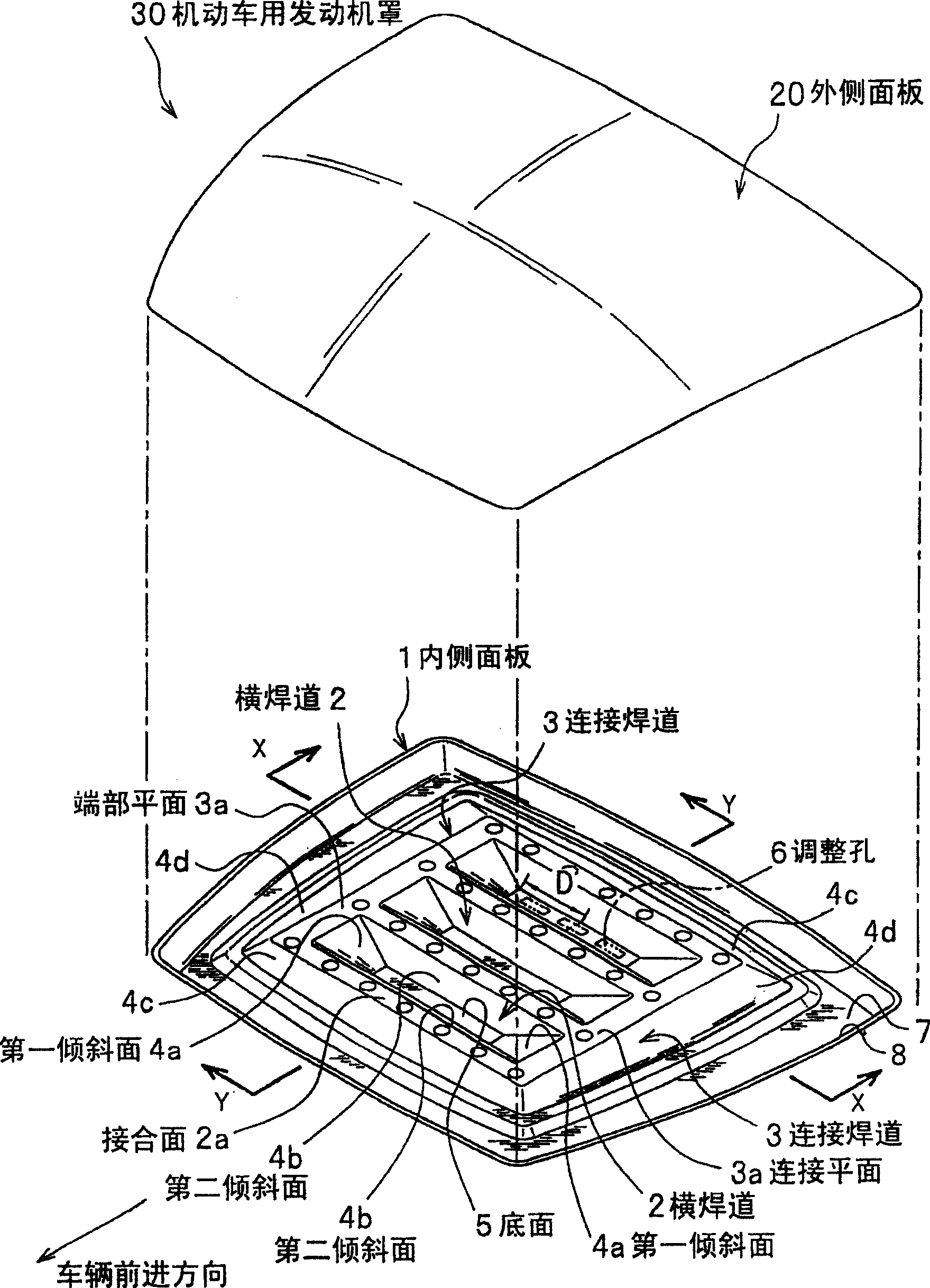

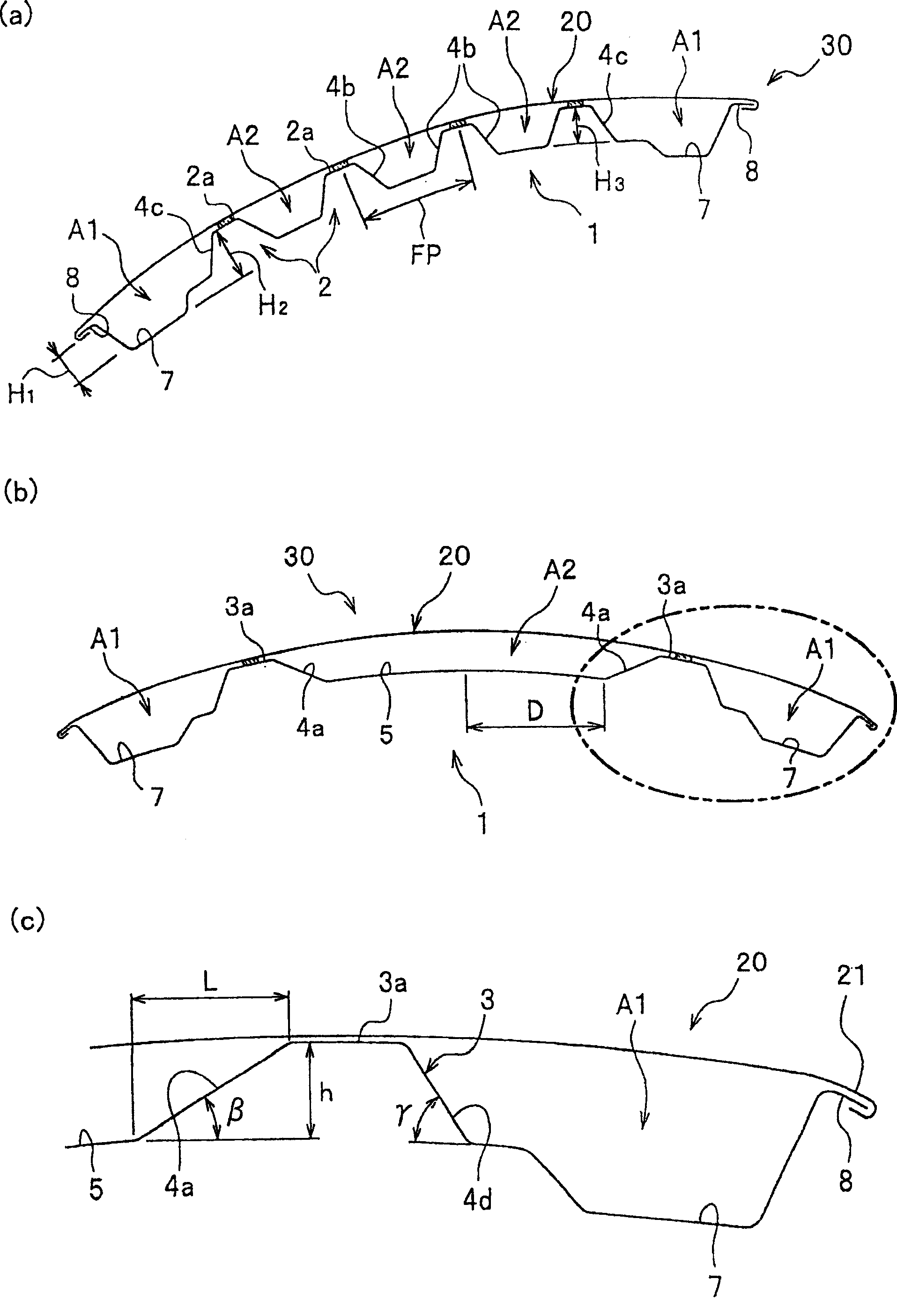

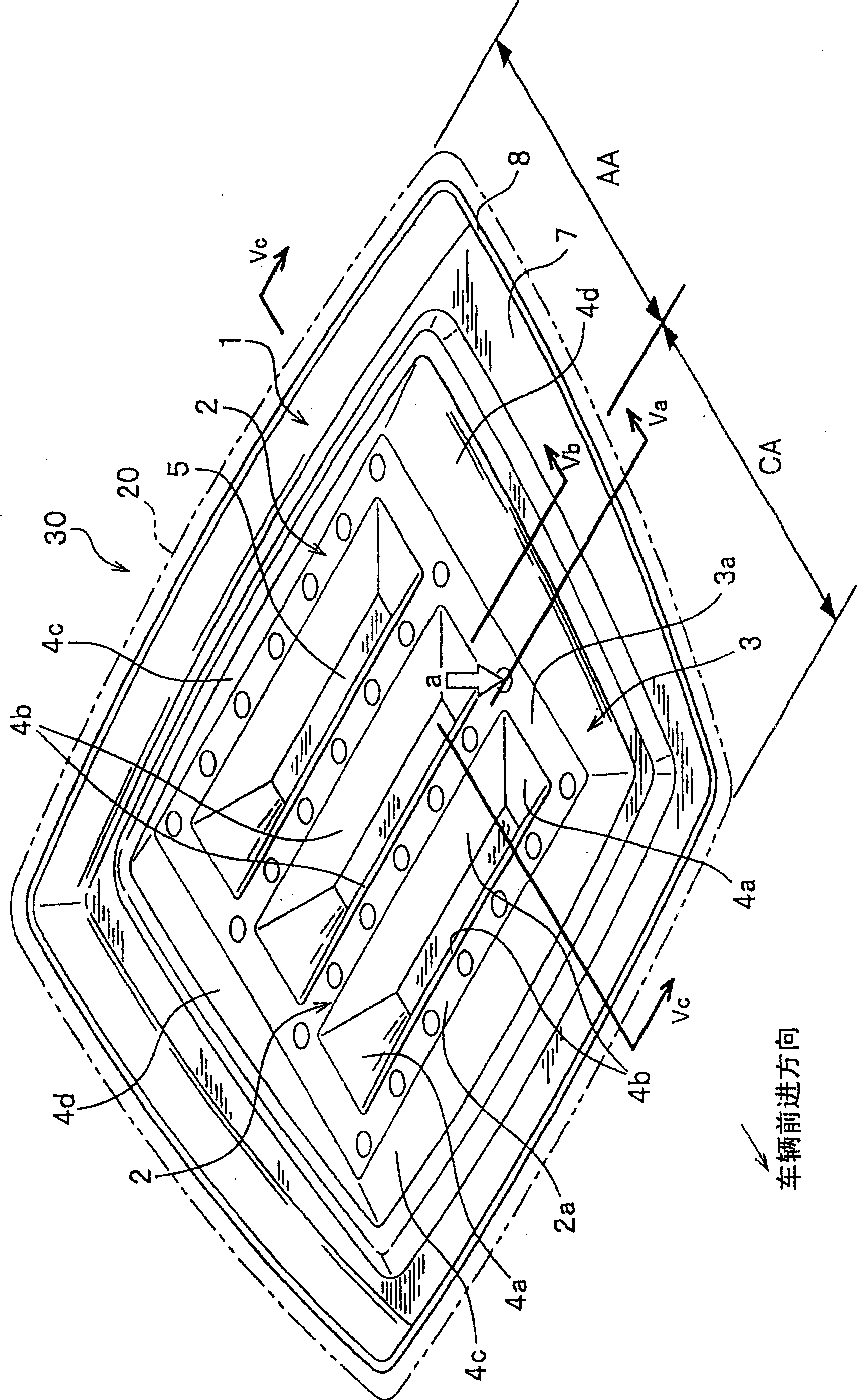

[0049] Such as figure 1 and figure 2 As shown, the motor vehicle hood 30 is formed in a cross-sectional structure in which the outer panel 20 and the inner panel 1 are joined, and the two panels 20, 1 are joined to form spaces A1, A2 between the two panels.

[0050] (outside panel)

[0051] Such as figure 1 As shown, the outer panel 20 is formed in a planar shape, or is made of a light-weight, high-tensile metal plate having a predetermined curvature, and the raw material metal is preferably steel, or an aluminum alloy of 3000, 5000, 6000, or 7000. The thickness of the outer panel 20 is preferably, for example, a steel plate of 1.1 mm or less, and an aluminum alloy plate of 1.5 mm or less. In addition, the outer panel 20 may be made of resin or a carbon fiber plate. In addition, the outer panel 20 is joined at its peripheral edge to the peripheral edge of the inner panel 1 described later by fitting, bonding, brazing, etc. by hemming, and between the outer panel 20 and ...

no. 2 approach

[0080] Next, a second embodiment of the present invention will be described. exist Figure 1 to Figure 6 In , the case where the inner panel 1 is used as the transverse weld bead 2 perpendicular to the direction of travel of the vehicle is described, but as Figure 7 As shown, it may be configured as a longitudinal bead 12 in a direction substantially parallel to the vehicle advancing direction. Figure 7 (a) and (b) are a perspective view and a cross-sectional view showing an inner panel of a motor vehicle hood according to a second embodiment; Figure 8 (a), (b) is a perspective view which shows the application example of the inner panel of the motor vehicle bonnet concerning 2nd Embodiment. In addition, since the structure which has already been demonstrated with the horizontal bead differs only in the direction, since it achieves substantially the same function, the same code|symbol is attached|subjected and the description is abbreviate|omitted.

[0081] Inner panel 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com