Electric pressure cooker

An electric pressure cooker and pot lid technology, which is applied to the improvement field of electric heating cookers such as electric pressure cookers and electric rice cookers, can solve the problems of high cost, complex structure and processing, inaccurate detection, etc., and achieves simple structure, low cost, and guaranteed The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

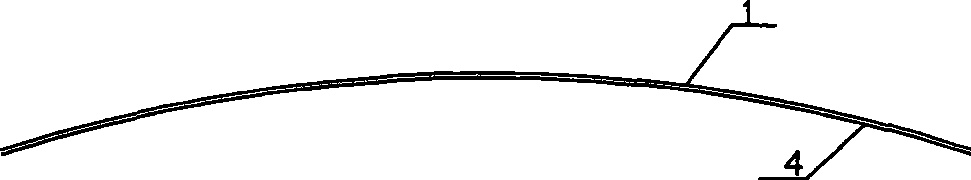

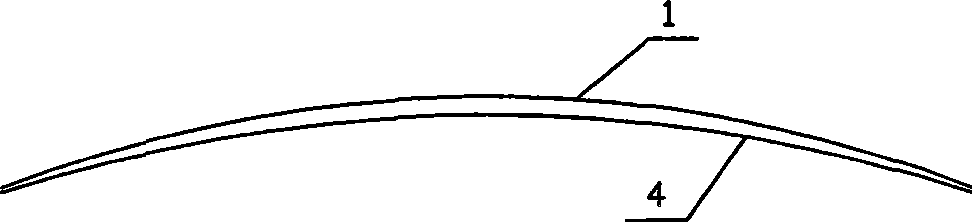

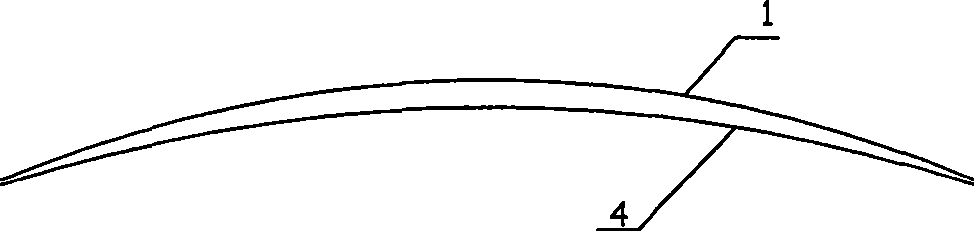

[0036] Such as Figure 1-Figure 4 Shown is the schematic diagram of the contact surface between the bottom of the pot liner and the heating plate in the prior art when it is cold, at 100°C, 200°C, and 300°C. The distance between them is 0, and the distance between them is 0.1mm at 100°C, 0.5mm at 200°C, and 1mm at 300°C. It can be seen that when the composite pot bottom structure is not used, its Heating will be uneven.

[0037] Such as Figure 5 , Image 6, shown in Fig. 7, Fig. 8, adopted the electric pressure cooker at the bottom of single-layer stainless steel pot liner of the present invention to comprise pot cover (not shown in the figure), shell, pot liner 1, inner cover 2, inner cover chassis 3 and setting The heating plate 4 and the control circuit on the inner cover chassis, the pot liner 1 is a stainless steel single-layer structure, and the bottom of the heating plate is provided with three or more supporting feet, and the supporting legs are equidistantly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com