Auxiliary switch

An auxiliary switch and thick shaft technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of thinning cam walls, occupying a lot of thickness space, poor mechanical strength of plastic cams, etc., to reduce the overall size and volume. , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

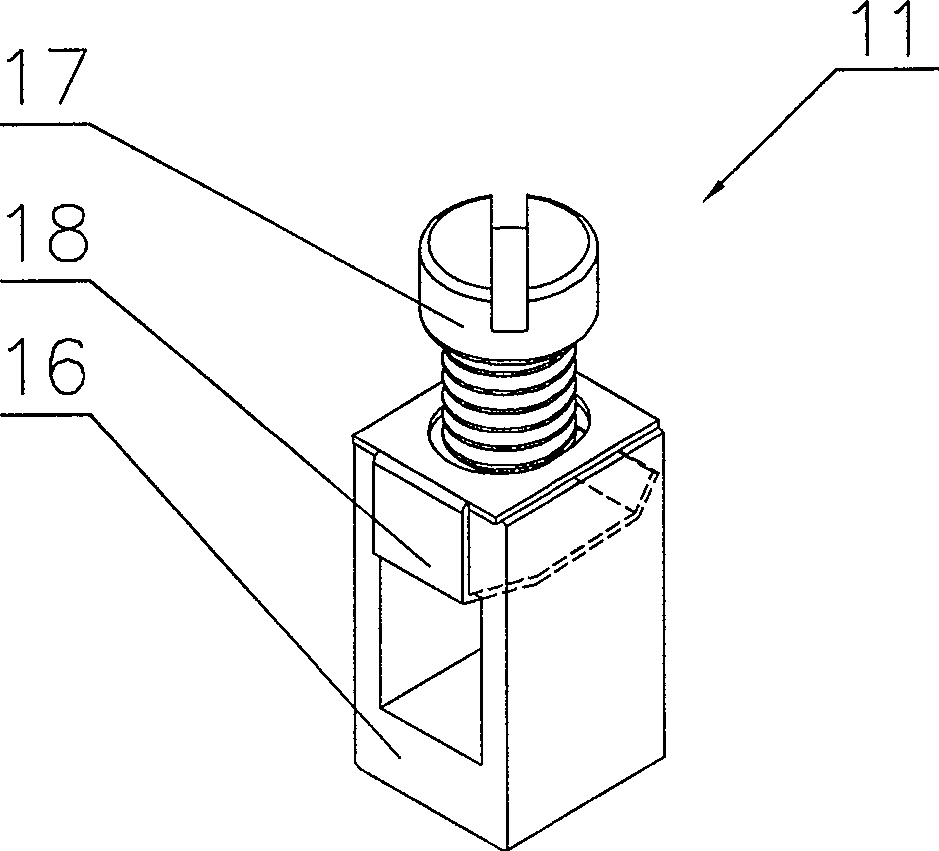

[0028] Such as Figure 1-6As shown, the first specific embodiment of the present invention is: an auxiliary switch, including a rotating shaft 1, a cover plate 2, a connecting bolt 3, a pull rod 4 and a multi-layer contact assembly 5, and each layer of contact assembly 5 includes a base 6 , moving contact 7, moving contact seat 8, static contact 9, spring 10, wiring device 11 and cam 12, wherein rotating shaft 1 is divided into thick shaft 13 and thin shaft 14 two parts, in thick shaft 13 and thin shaft A limiting seat 15 is provided on the thick shaft 13 at the junction of 14 . There are four wiring devices 11 in each contact assembly 5 , and each wiring device 11 is composed of a crimping frame 16 and a screw 17 , and a lifting piece 18 is also provided between the crimping frame 16 and the screw 17 . The thick shaft 13 and the thin shaft 14 are two metal shafts with different thicknesses. In this embodiment, square shafts (i.e. quadrilateral shafts) are used. One end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com