General explosion-prevention safe air valve for automobile tyre

A car tire safety technology, applied to tire inflation valves, tire parts, vehicle parts, etc., can solve problems such as inability to use air nozzles, and achieve the effects of preventing tire blowout accidents, easy installation, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

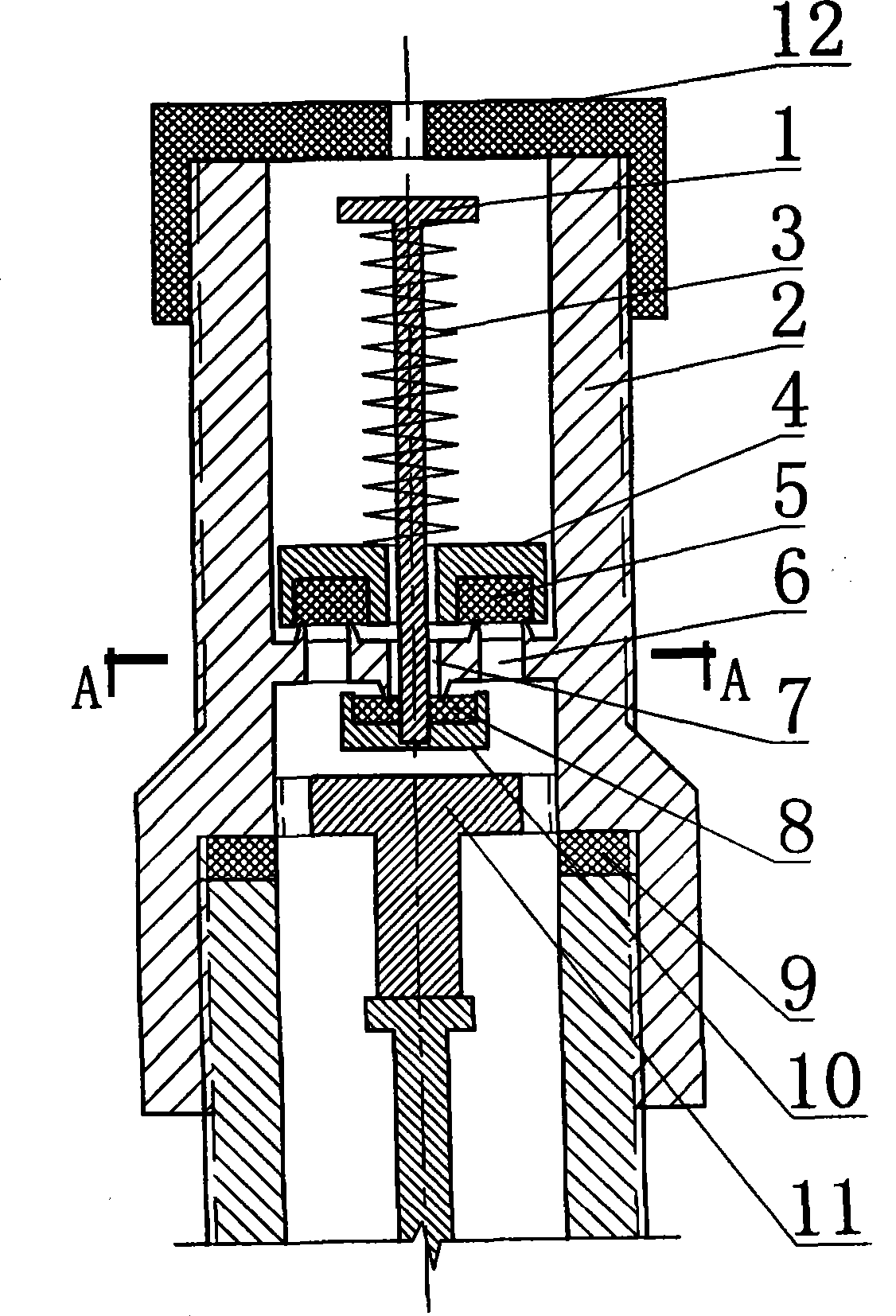

[0021] The universal non-explosive safety air nozzle for automobile tires consists of a pressure rod 1, a nozzle body 2, a spring 3, an air pressure bowl 4, an air sealing rubber ring 5, an air release hole 6, an air filling hole 7, an inflatable sealing ring 8, a combined sealing ring 9, and an air sealing Bowl 10, ejector rod 11 and nozzle cap 12 are characterized in that: the nozzle body 2 is threadedly connected with the original gas nozzle barrel, and there is a partition inside the nozzle body 2, and the partition has a vent hole 6 and an inflation hole 7. Above the separation is the pressure bowl 4, the air sealing rubber ring 5 sticks in the annular space at the bottom of the pressure bowl 4, the pressure rod 1 runs through the through hole in the middle of the pressure bowl 4 and the inflation hole 7 of the nozzle body 2, the lower end of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com