Magnetofluid bearing

A magnetic fluid and bearing technology, applied in bearings, shafts, bearings, mechanical equipment, etc., can solve problems affecting bearing performance and inconvenient repairing of assembly machines, and achieve low friction, enhanced magnetic properties, improved sealing performance and load-carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

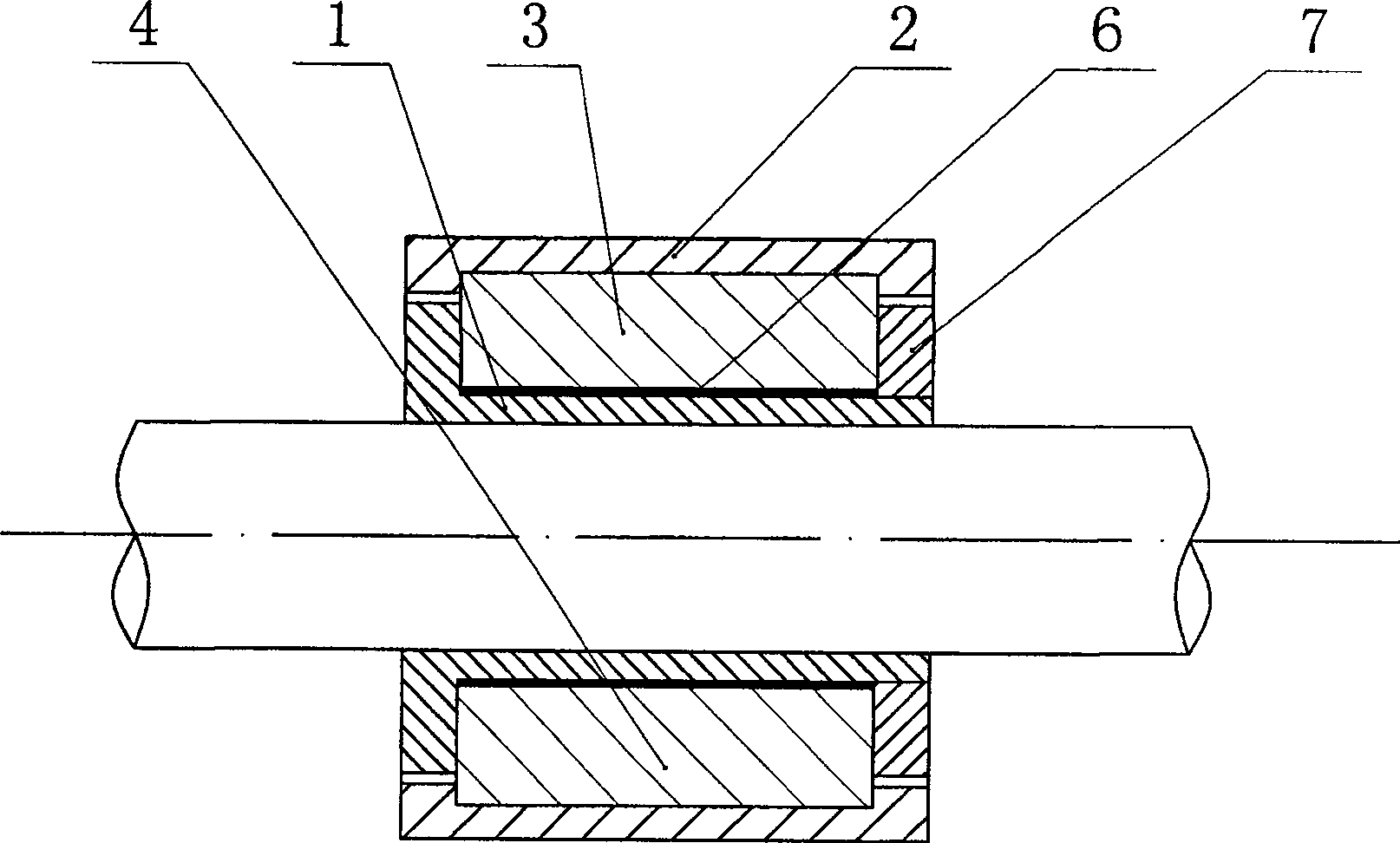

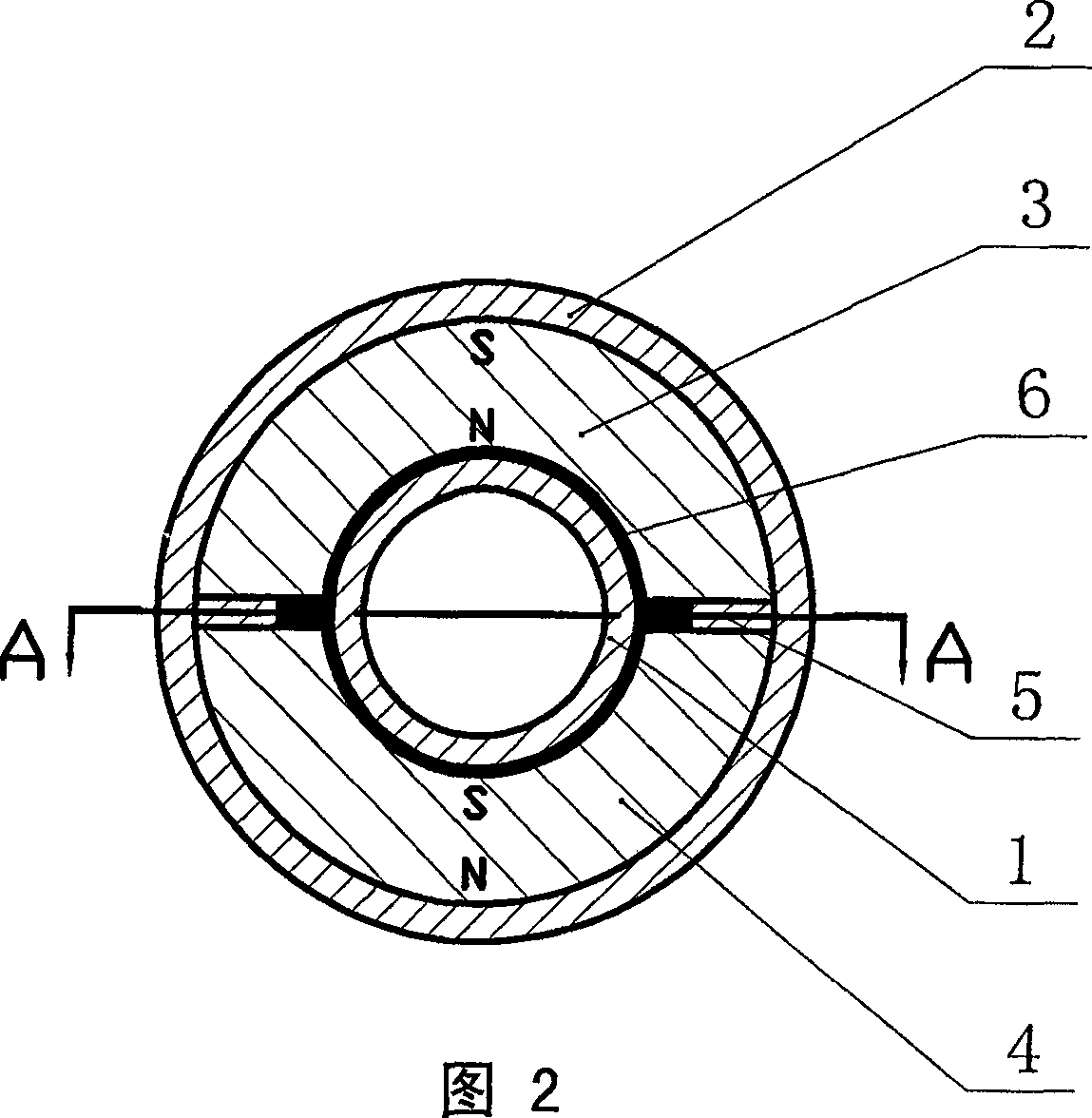

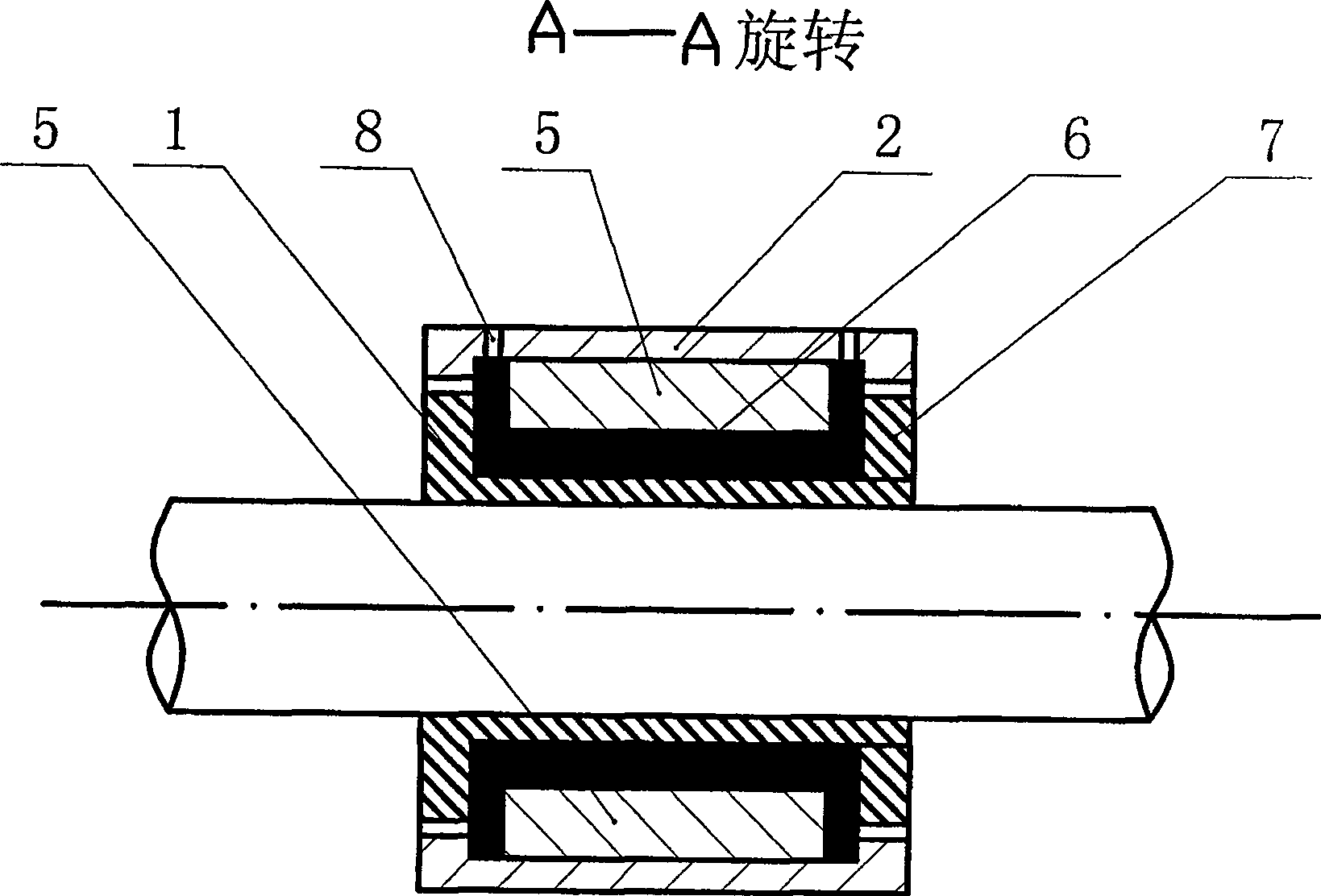

[0011] Such as figure 1 ,figure 2, image 3 As shown, the present invention includes a bearing inner sleeve 1 with a shoulder at one end, a bearing outer sleeve 2, a permanent magnet, a magnetic fluid, and an inner sleeve fixing ring 7. The permanent magnets 3 and 4 separate the annular columnar permanent magnets formed by separators 5, and the bearing cover 2 is fixedly mounted on the outer circle of the annular columnar permanent magnets. The radial width of the separators 5 is smaller than the width of the permanent magnets. Two half-ring columnar permanent magnets 3 and 4 form a gap near the inner ring, and the length of the separator 5 is smaller than the length of the permanent magnet on the axial length so that the two half-ring columnar permanent magnets 3 and 4 form a gap at both ends. The bearing outer sleeve 2 is provided with a magnetic fluid injection hole 8 corresponding to the two half-ring columnar permanent magnets 3 and 4 in the gap at the shaft end, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com