Automatic valve in use for water supply apparatus of coffee maker

A technology for water supply devices and automatic valves, applied in valve devices, mechanical equipment, engine components, etc., can solve the problems of difficult air discharge, poor adaptability, damage to water pumps, etc., and achieve simple and compact structure and large pressure adjustable range , Facilitate the effect of safe pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

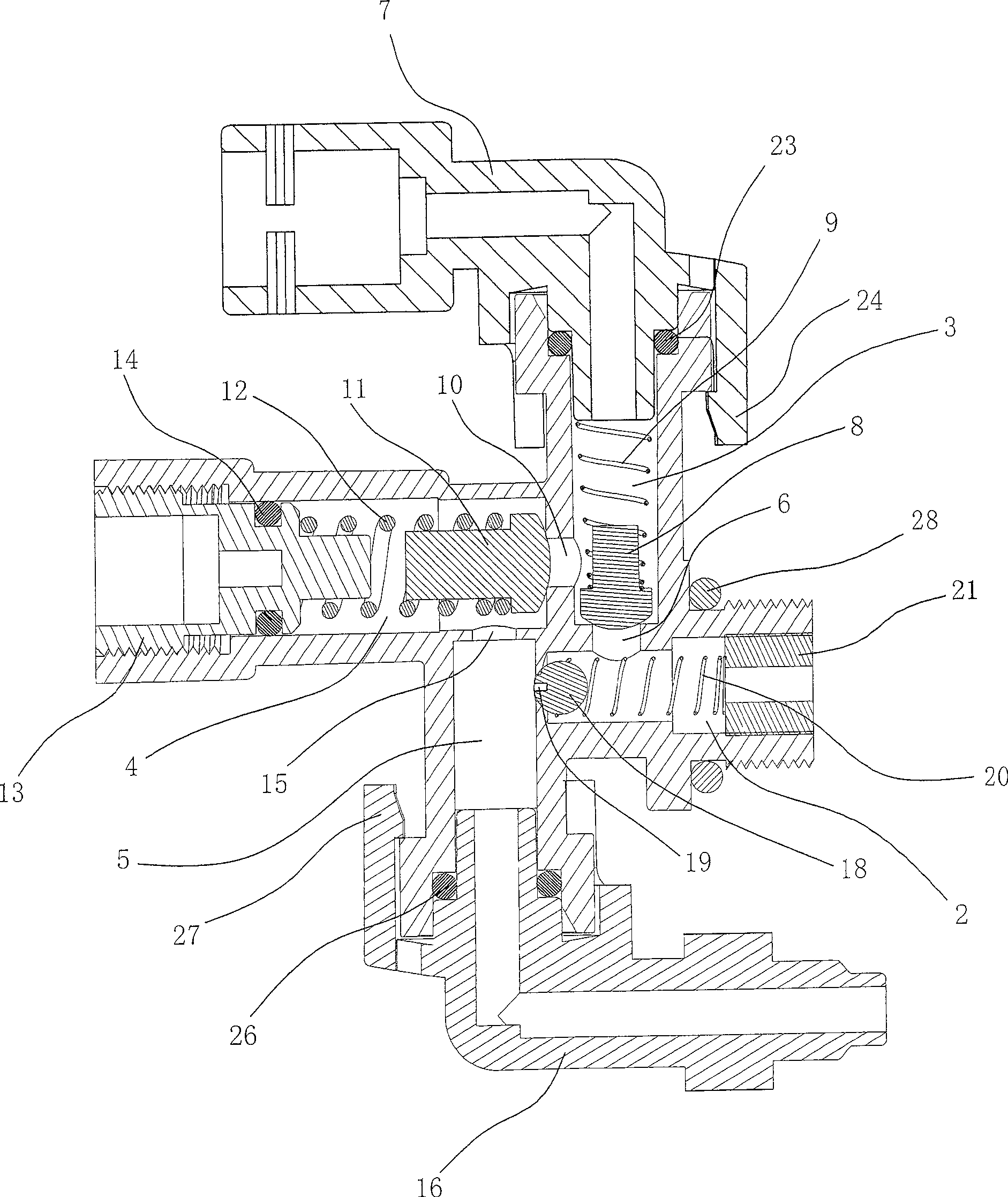

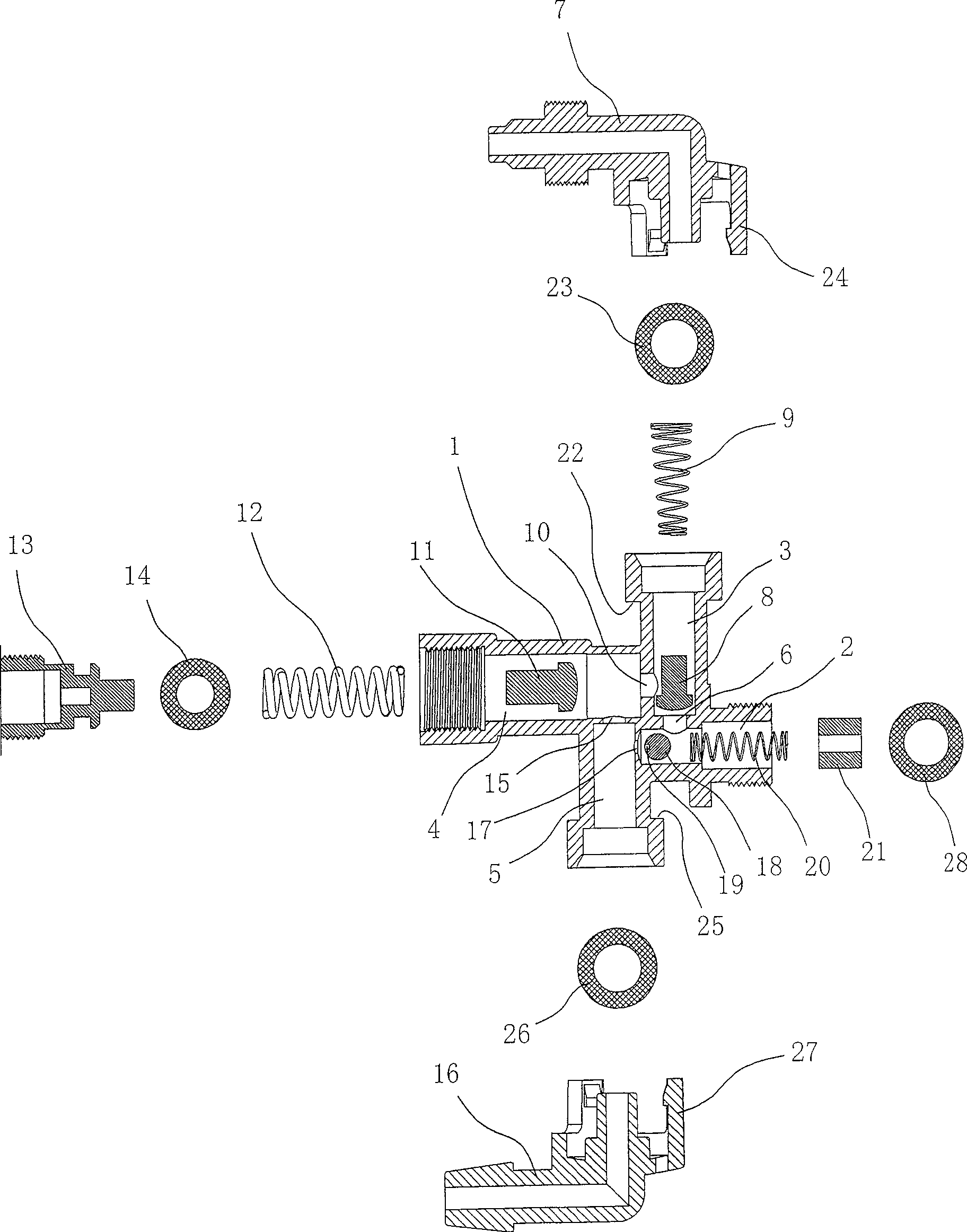

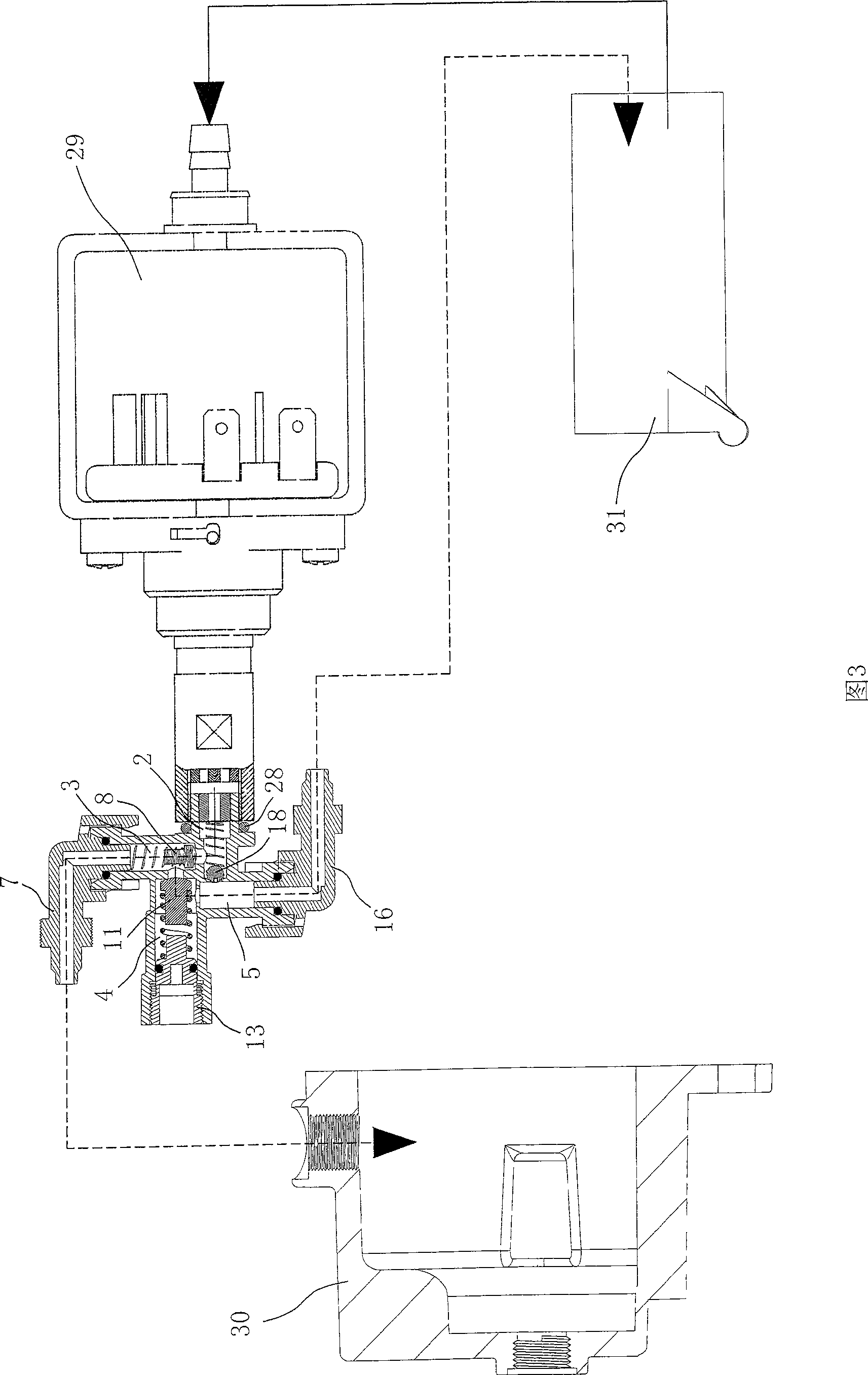

[0022] like figure 1 ~ Figure 3 schematically shows a preferred embodiment of the present invention. like figure 1 As shown in Figure 3, the automatic valve for the water supply device of the coffee machine in this embodiment has a valve body 1, and the valve body 1 has a water inlet chamber 2, a water outlet chamber 3, a pressure regulating chamber 4 and a return chamber 5; wherein,

[0023] The head of the water outlet chamber 3 communicates with the water inlet chamber 2 through the water outlet hole 6 provided on the side wall of the water inlet chamber 2, and the tail is sealed and connected with an outlet pipe joint 7, and a one-way valve spool 8 is installed in the water outlet chamber 3; The head of the directional valve spool 8 rests on the water outlet hole 6, and the rear part holds the one-way valve compression spring 9, and the rear end of the one-way valve compression spring 9 is limited by the outlet pipe joint 7, so that the one-way valve valve The core 8 alw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com