Gear unit for cable window lift systems unit for manual and motor-driven operations

A technology for lifting systems and gear sets, applied to manual mechanisms, power control mechanisms, windows, etc., can solve problems such as low mechanical efficiency, obstruction, and excessive structural volume, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

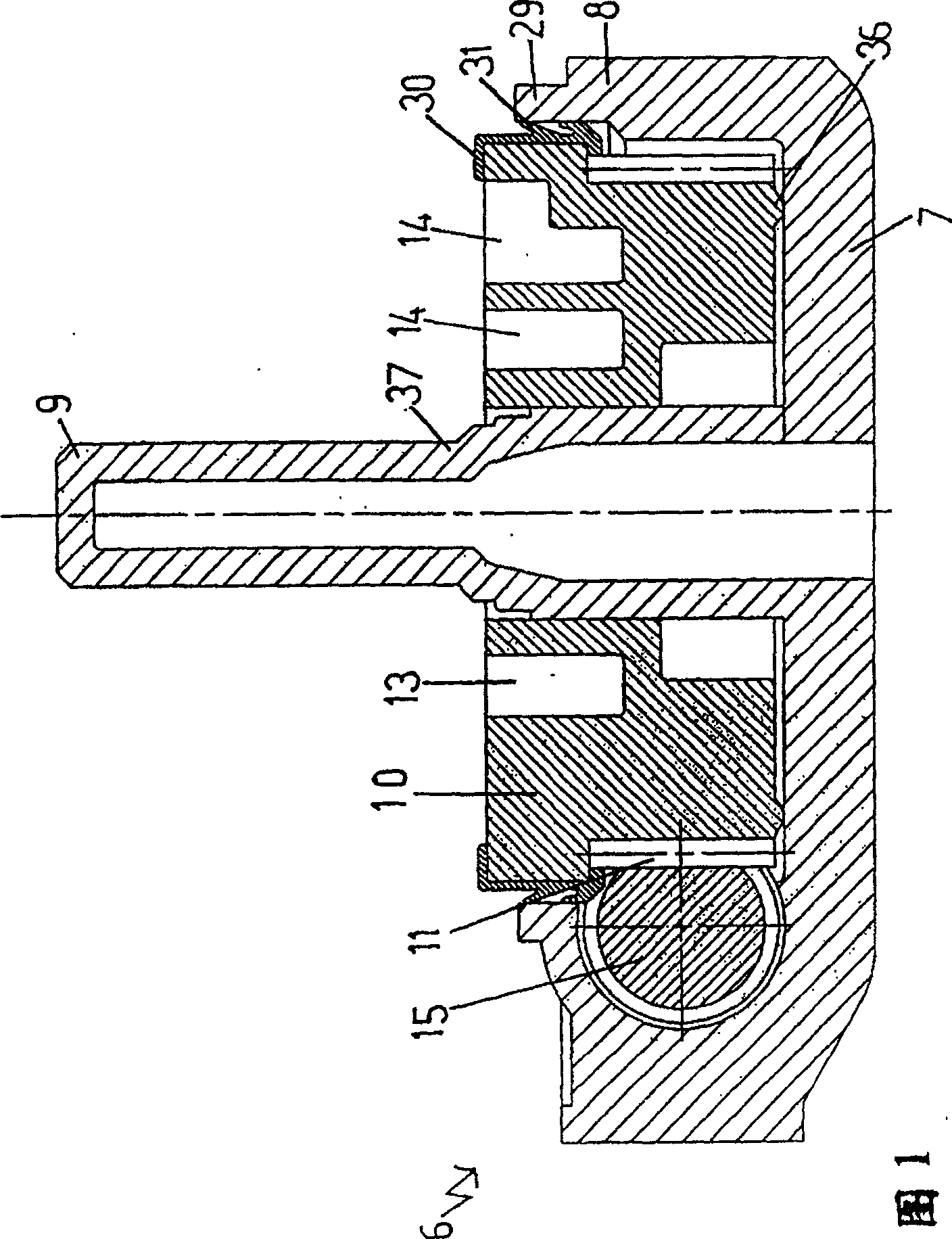

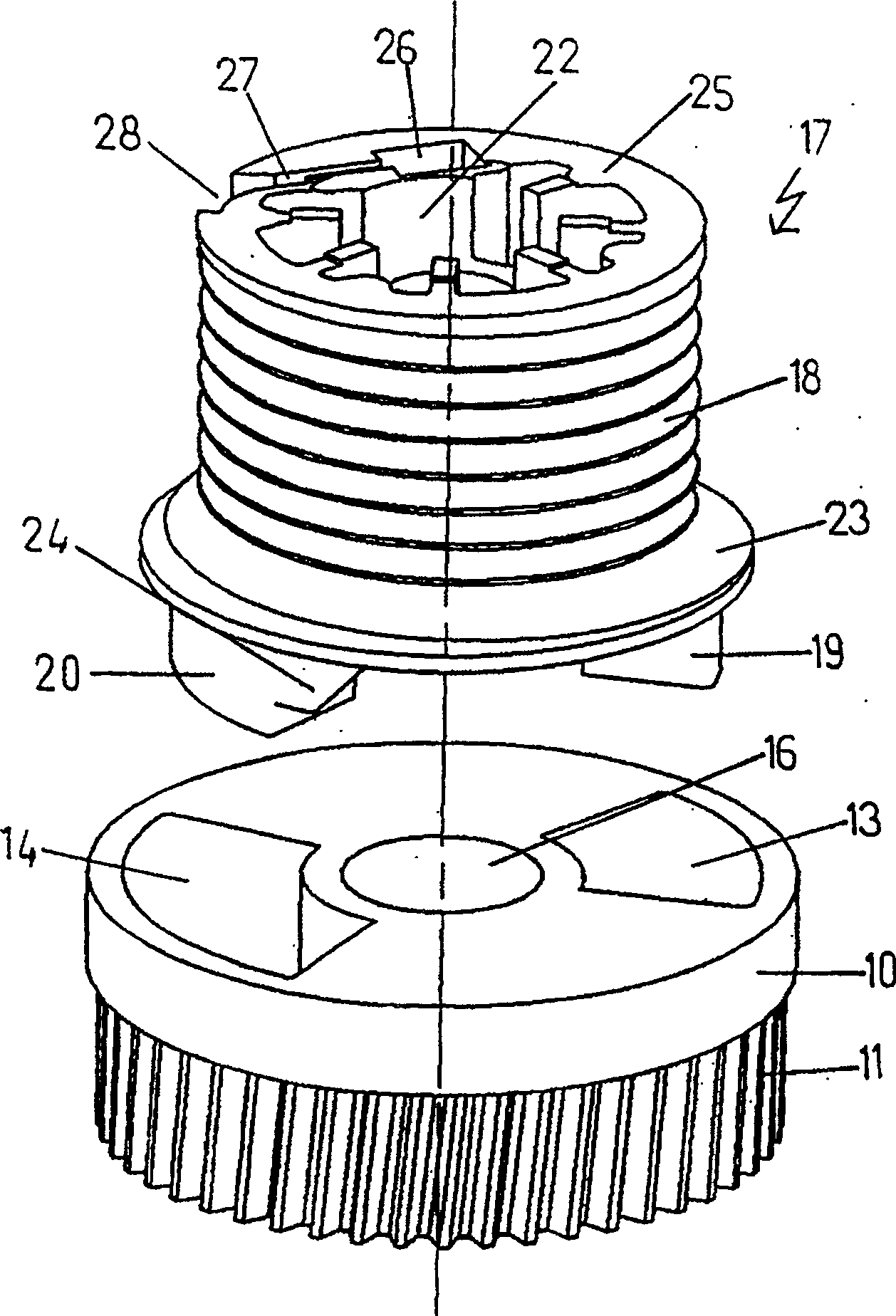

[0037] FIG. 1 shows a gear set according to the invention in a cross-sectional view. As shown in FIG. 1 , a turbine 10 is accommodated in a gearbox part 6 consisting of a case bottom 7 and side walls 8 extending perpendicular to the case bottom 7 . Protruding perpendicularly from the bottom 7 is a pivot pin 9 which can be designed as a metal or plastic pin and is firmly connected to the bottom 7 . Pivot pin 9 acts as turbine 10 with image 3 The axis of rotation of the cable drum shown in . The drive shaft of the electric motor extends through a cylindrical hole in the left edge of the gearbox part 6 and has a drive worm 15 meshing with the worm gear 10 at the front end of the drive shaft. The worm gear 10 and the drive worm 15 form a worm gear whose gear ratio is defined by the teeth 11 of the drive worm 15 and the worm gear 10 .

[0038] According to the present invention, the gear ratio of the worm gear is in the range from about 1:38 to about 1:55, preferably in the ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com