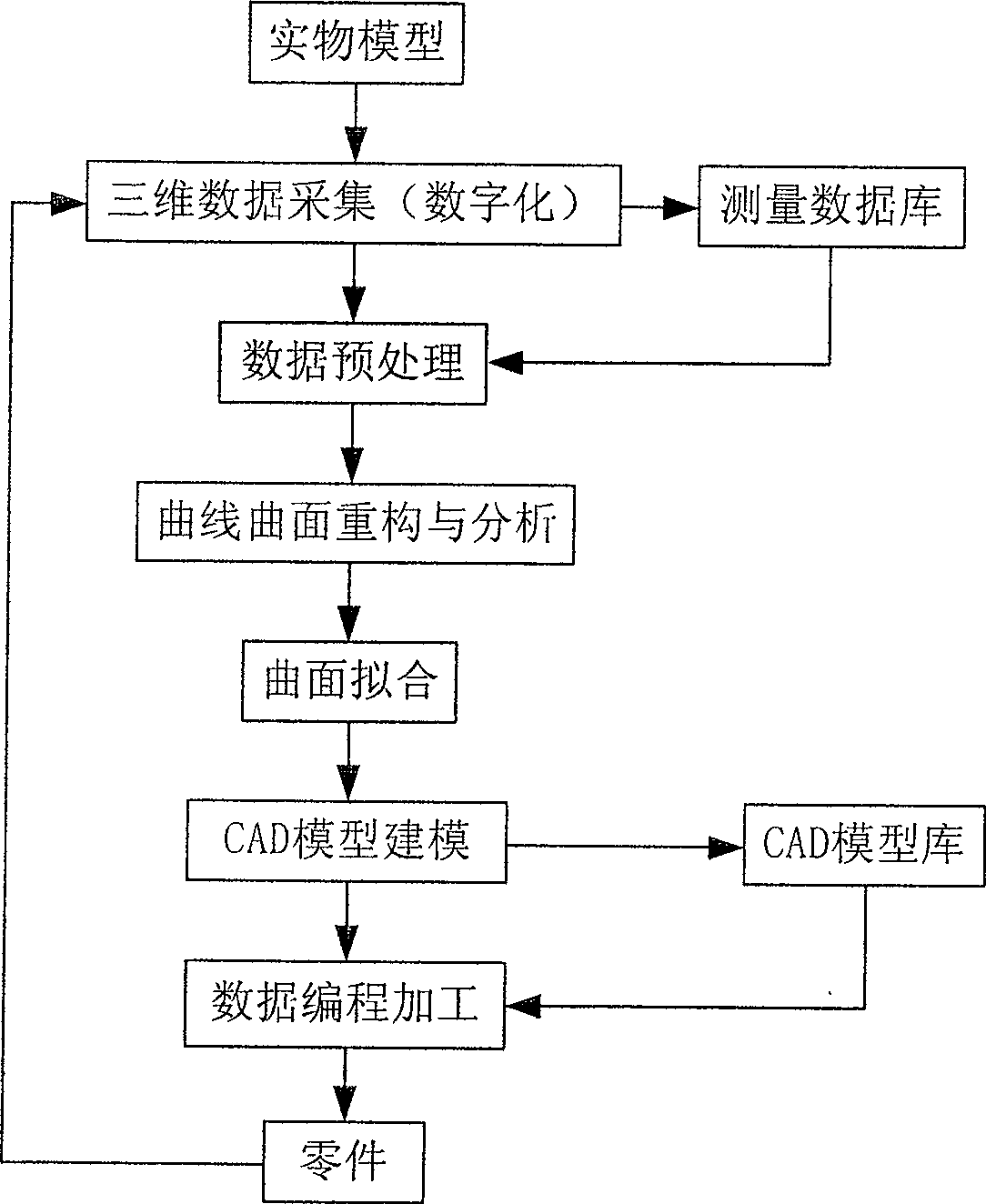

Self-correcting method for optical grating based on linear phase position

A self-correcting, straight-line technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of inaccurate measurement accuracy of grating waveform phase shift, low measurement point density, and increased difficulty in finding fringes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

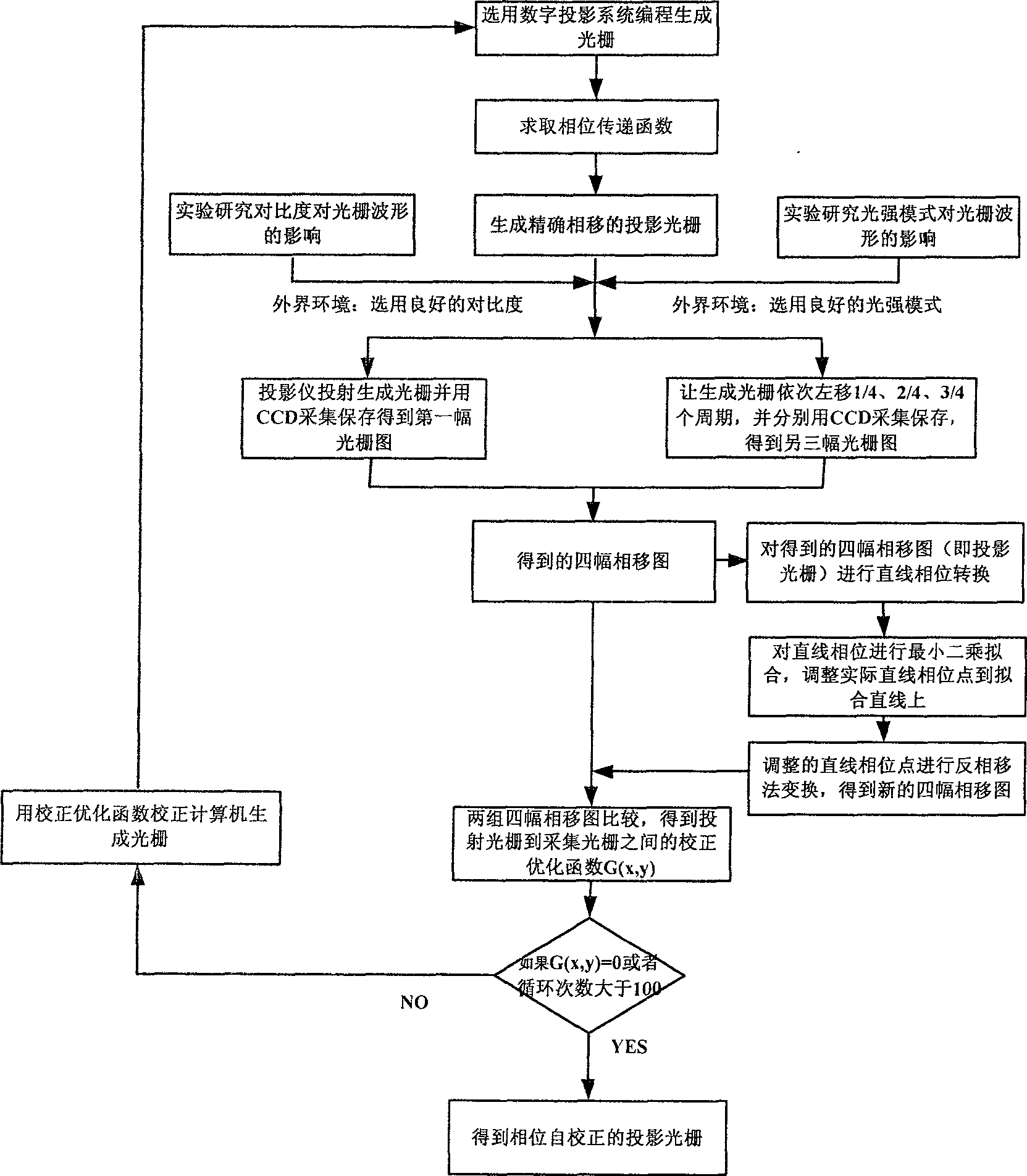

[0055] The specific implementation manners of the present invention will be further described below in conjunction with the drawings. According to the above method, the grating self-calibration operation is realized by using C++ programming on the VC++6.0 platform in the Windows operating system.

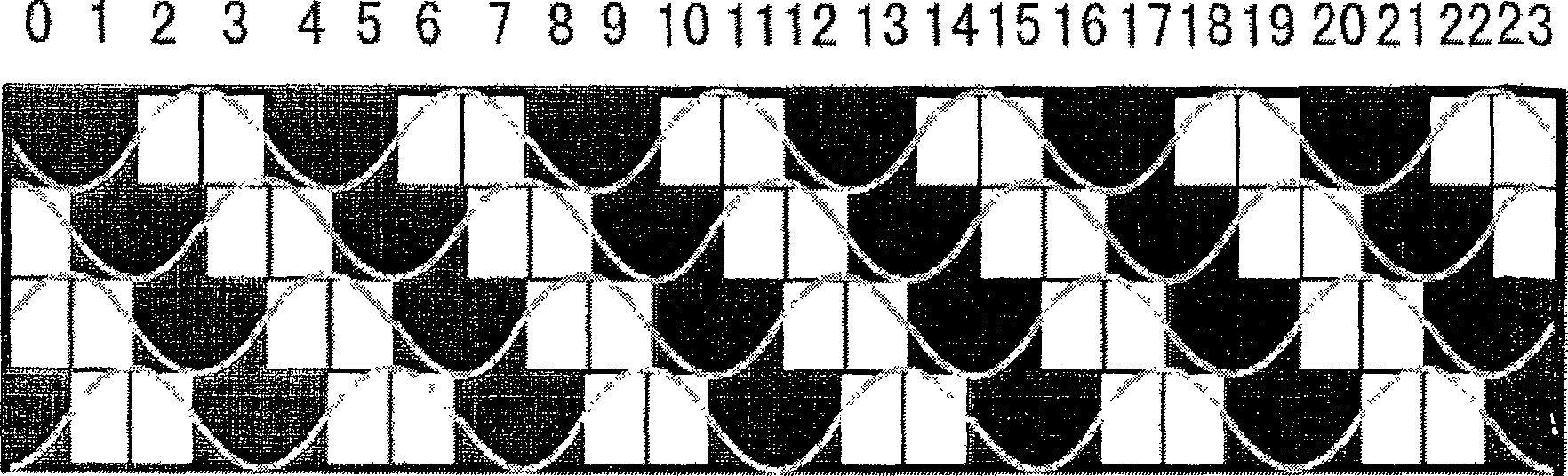

[0056] Firstly, each factor is analyzed from the perspectives of grating sine, precise phase shift, and periodicity, and targeted improvement methods and measures to improve accuracy are put forward to provide a basis for the final grating self-correction method; and in grating projection In the measurement, the main problem affecting the measurement accuracy is the projection technology. The projection in the grating projection measurement requires high contrast, intensity and good light intensity mode. Therefore, we can evaluate the accuracy of phase-shift grating projection measurement from the perspective of the sine and periodicity of the projected grating waveform, and convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com