Length measuring method

A technology of length measurement and length measurement, applied in the direction of measurement device, conversion sensor output, instrument, etc., can solve the problems of large measurement error, user inconvenience, poor versatility, etc., to achieve small error, improve measurement accuracy, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

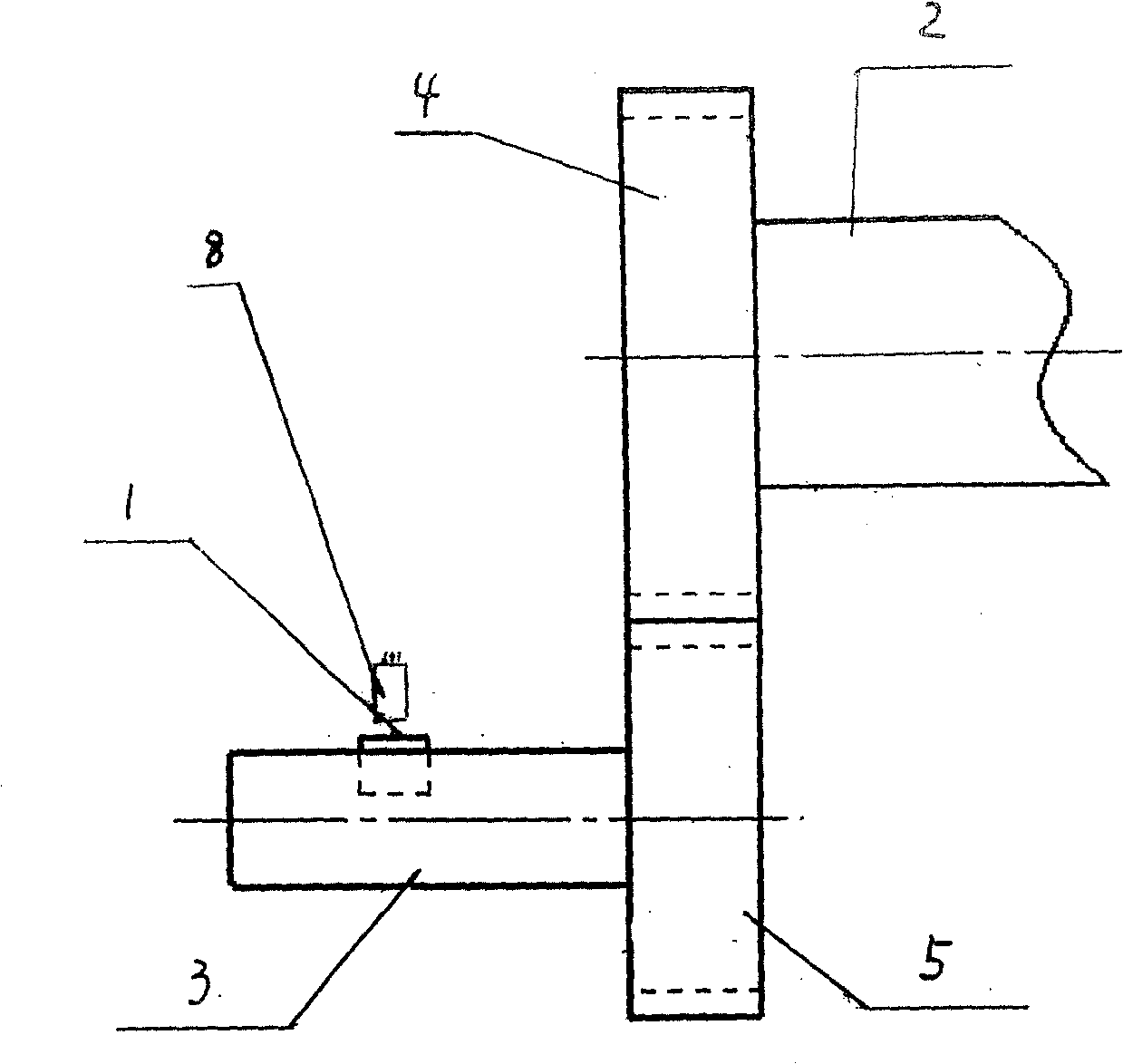

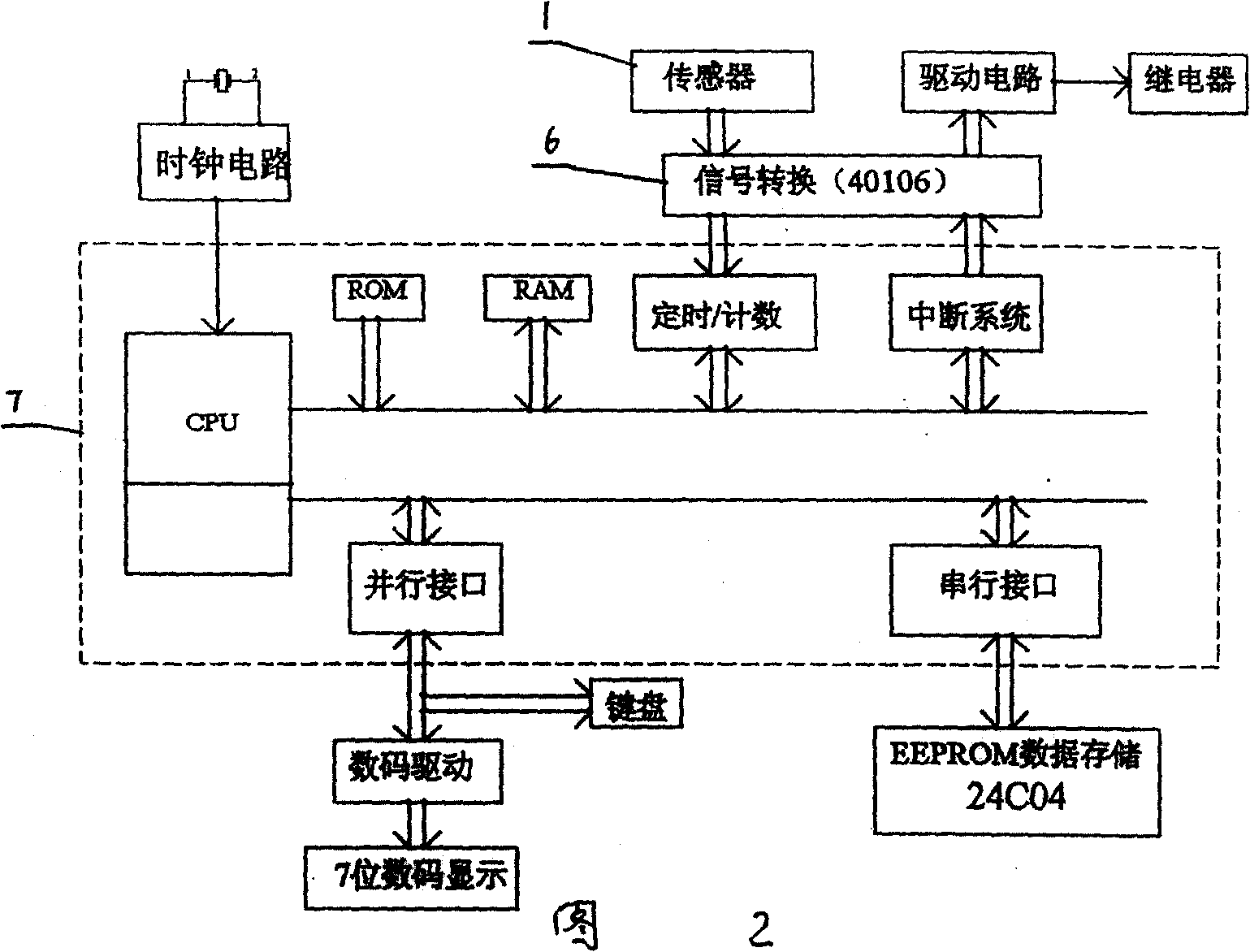

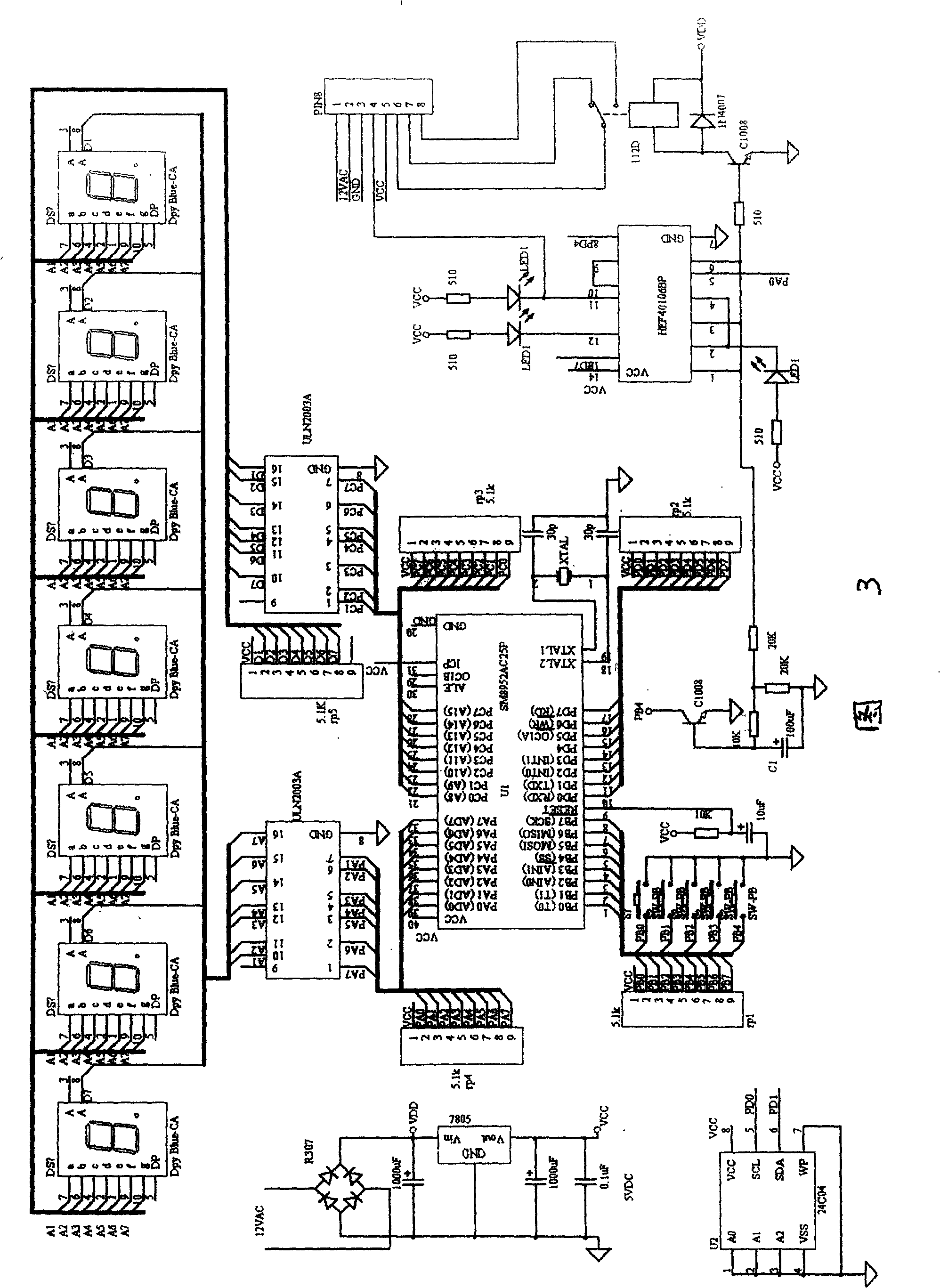

[0019] With reference to accompanying drawing, the length measuring method described in embodiment, comprises the following steps:

[0020] A. Changing the sampling permanent magnet 1 from being installed on the measuring axis 2 to being installed on the sampling axis 3, the installation position of the sensor 8 is also changed from being close to the measuring axis 2 to being close to the sampling axis 3, and the measuring axis 2 passes through The meshed gear set is connected with the sampling shaft 3, and the signal output end of the sensor 8 is connected with the input end of the signal converter 6 in the electronic length meter;

[0021] B. Use the parameter setting button on the panel of the electronic length measuring instrument to input the diameter of the length measuring axis 2 of the strip to be measured, the gear transmission ratio between the length measuring axis 2 and the sampling axis 3 to the electronic length measuring instrument at the measurement site In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com