Method for producing high grade of diesel oil by charking full distillate oil

A technology for coking whole distillate oil and coking heavy distillate oil, which is applied to the processing field of coking whole distillate oil, can solve the problems of easy coking, influence on diesel yield, influence on stable operation of production equipment, etc., so as to reduce energy consumption and facilitate stable operation. , the effect of reducing gas yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1

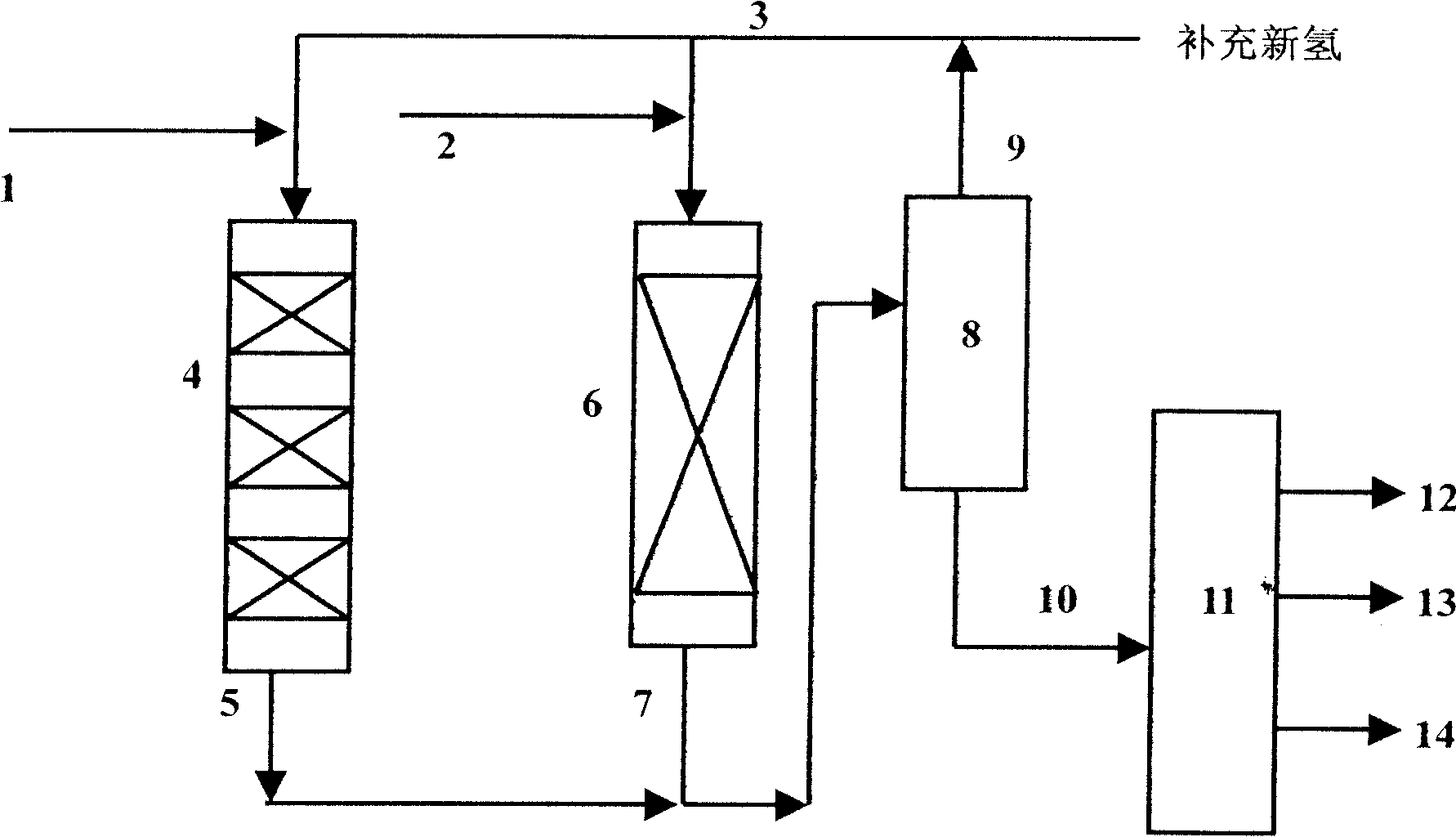

[0029] The flow chart of embodiment 1~4 sees figure 1 , the comparative example is that the coking gasoline and diesel raw materials are directly entered into the hydrofinishing reaction zone without fractionation, and the hydrofinishing catalyst is filled with a hydrogenation protecting agent, and its loading volume is 20% of the volume of the hydrofinishing catalyst, and the subsequent process is the same figure 1 .

[0030] The hydrorefining catalyst used in each embodiment and comparative example is the FH-98 (FH-98 is the catalyst brand) that Wenzhou Catalyst Factory produces, and the hydrogenation pretreatment catalyst is the 3996 that Fushun Petrochemical Company Catalyst Factory produces (3996 is catalyst brand), the hydrogenation protection agent is FZC-102 (FZC-102 is the catalyst brand) produced by the pilot test base of Fushun Petrochemical Research Institute, and the hydrogenation protection agent is filled before the hydrogenation pretreatment catalyst, and its f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com