Liquid crystal display panel and method for producing the same

A liquid crystal display and display area technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem that the sealant 32c cannot be fully cured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] A liquid crystal display panel and a method of producing the liquid crystal display panel according to embodiments of the present invention will be described below with reference to the accompanying drawings.

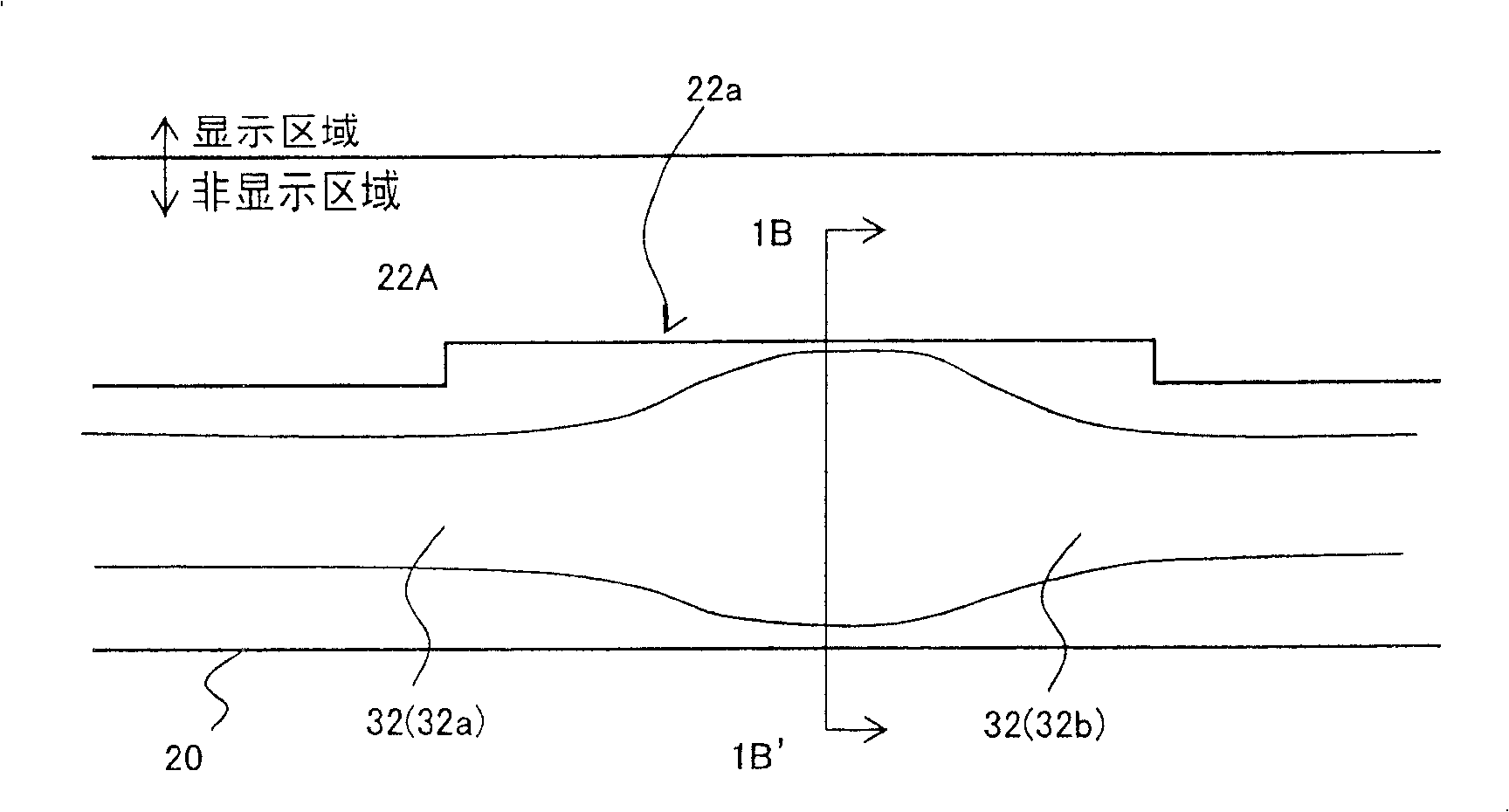

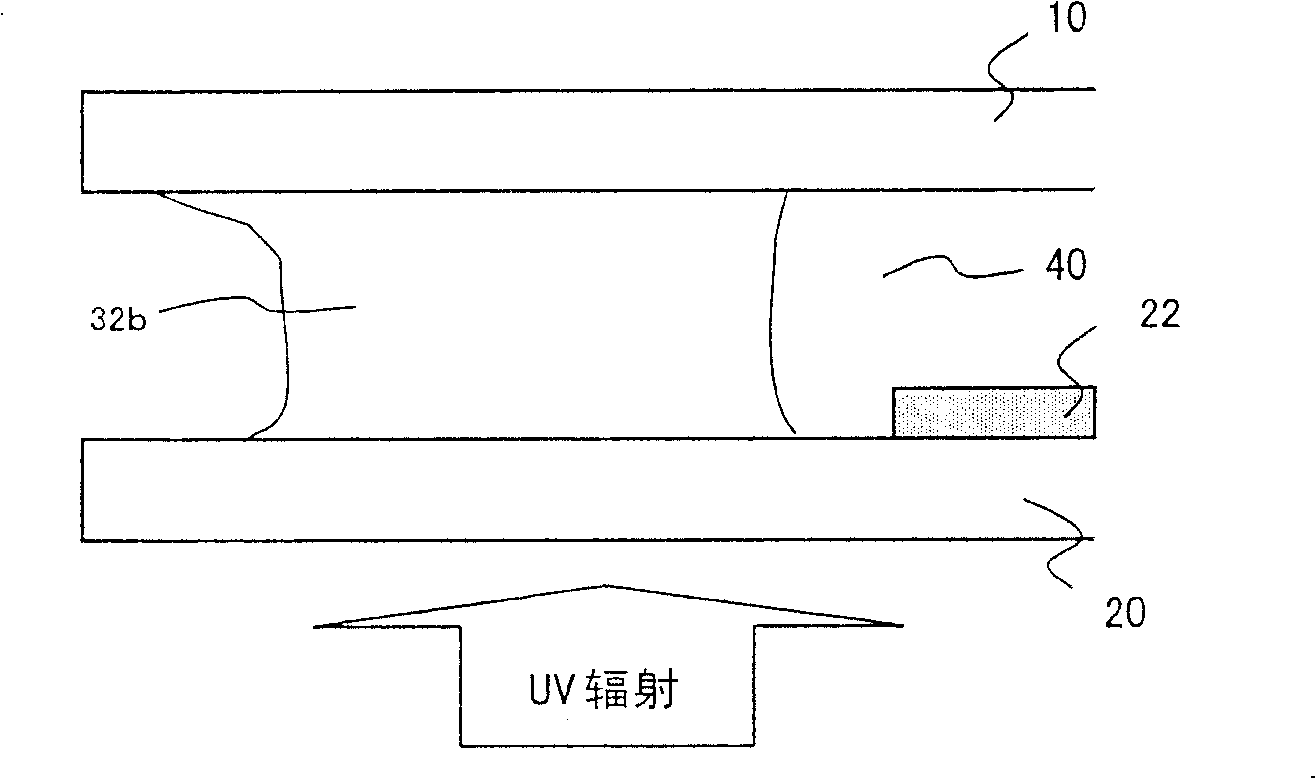

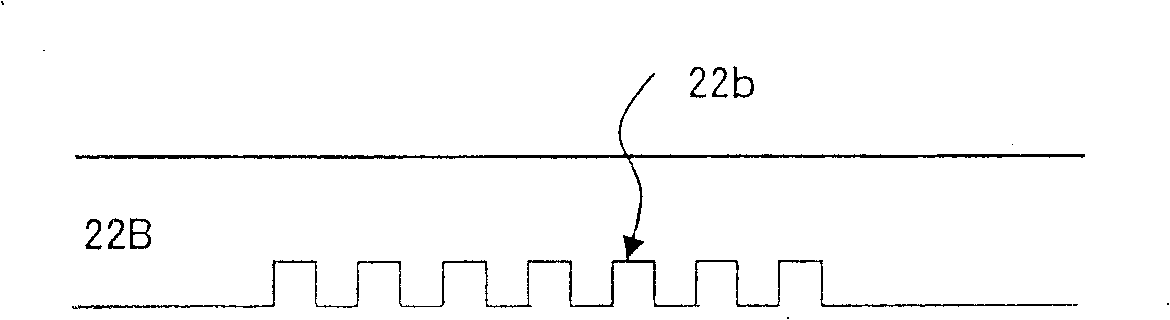

[0091] Such as Figure 1A and 1B As shown in , the liquid crystal display panel according to the embodiment of the present invention includes: a TFT substrate 10, a color filter substrate 20, a liquid crystal layer 40 disposed between the TFT substrate 10 and the color filter substrate 20, and surrounding liquid crystal layer 40 The sealing part 32 . The liquid crystal display panel has a display area and a non-display area surrounding the display portion. The color filter substrate 20 has a first light-shielding layer 22A provided in the non-display area at the end closer to the display area. The first light-shielding layer 22A has a concave portion (light-transmitting portion) 22a provided near the outer edge. The width of the sealing portion 32 is allowed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com