Floor drain

A floor drain and floor drain cover technology, applied in the field of components, can solve the problems of leaking and changing holes, and achieve the effect of solving the problem of changing holes, prolonging the time interval of cleaning, and preventing direct leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

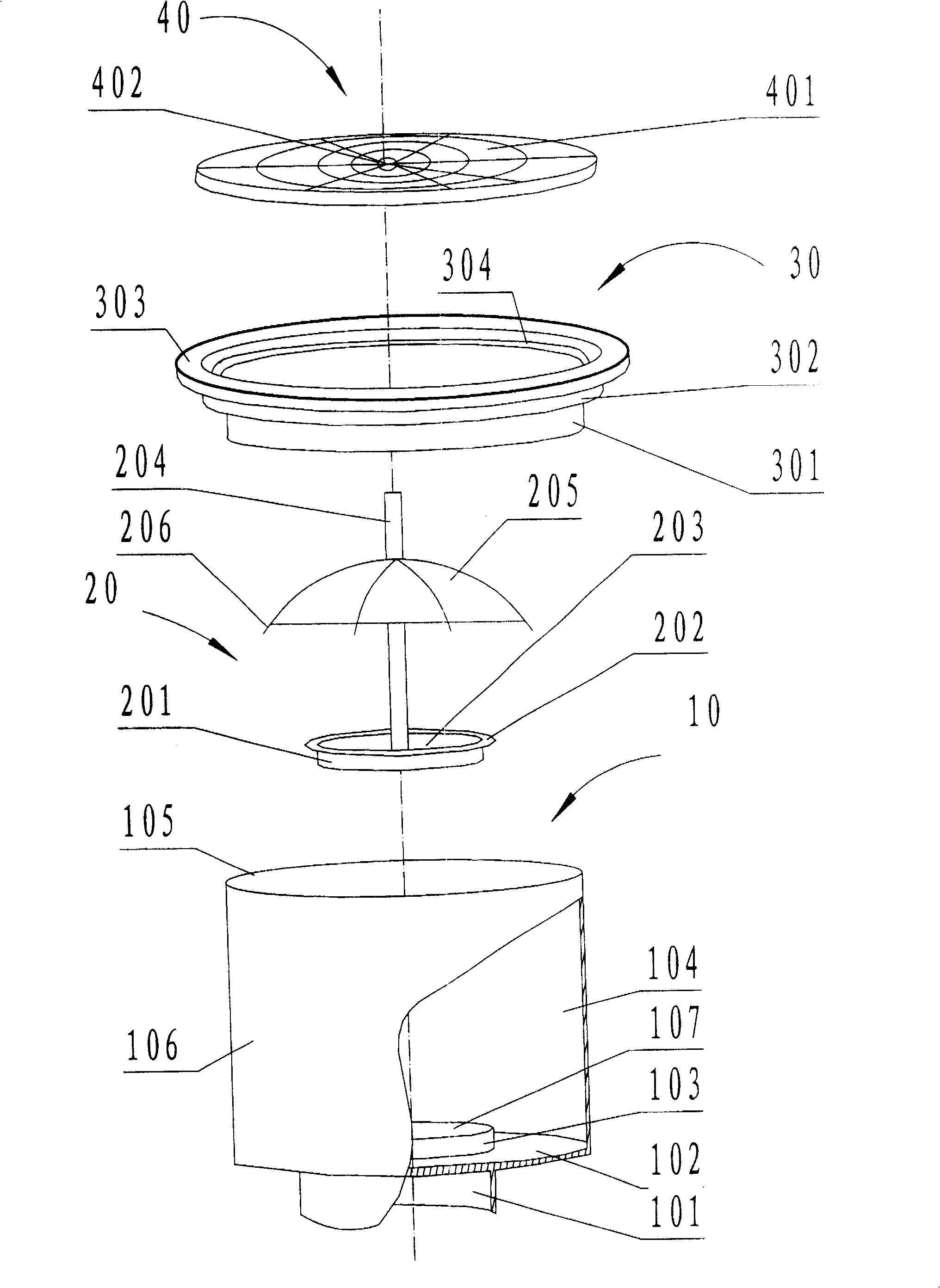

[0011] The serial numbers in the figure indicate respectively: floor drain main body 10, water pipe connection 101, floor drain bottom plane 102, water seal pipe 103, floor drain chamber 104, upper port 105, outer wall 106, water seal pipe port 107; screen block assembly 20, screen block 201, Screen skirt 202, screen bottom plane 203, handle 204, sealing bowl 205, convex part 206; floor drain cover base 30, base steps 301, 302, base upper plane 303, base inner steps 304; floor drain cover 40, grid 401, nut 402.

[0012] In the figure, the floor drain main body 10 is in the shape of a cylinder, and it is composed of three parts: the outer wall 106, the bottom surface of the floor drain 102 and the short pipe. The short pipe in the floor drain chamber 104 forms a water pipe connecting pipe 101 downward, and becomes a water seal pipe 103 upward, and the water seal pipe at the bottom The distance between the horizontal plane where the port 107 is located and the horizontal plane w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com