Composite cellulose pulp and method for producing same

A technology of composite cellulose and pulp, applied in the direction of cellulose/protein conjugated artificial filament, fiber treatment, chemical post-treatment of fiber, etc., can solve the problem of cellulose content, whiteness, viscosity, ash, iron content and filterability cannot meet the technical requirements of composite viscose fiber pulp, and cannot adapt to the production of new composite cellulose pulp, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A new type of composite cellulose pulp, which is made of any combination of any two or more raw materials of cotton linters, wood, hemp, and bamboo. The manufacturing method comprises the following steps: seasoning, washing, washing, beating and thawing, mixing, impurity-removing washing, pre-acid, pre-chlorine, bleaching, acid treatment, impurity-removing washing and papermaking.

Embodiment 2

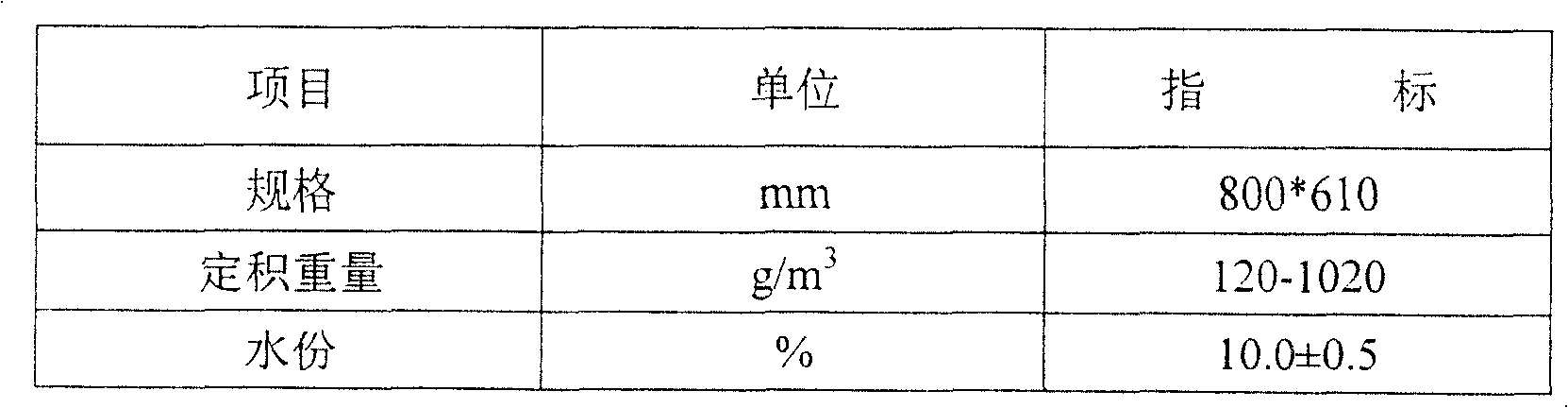

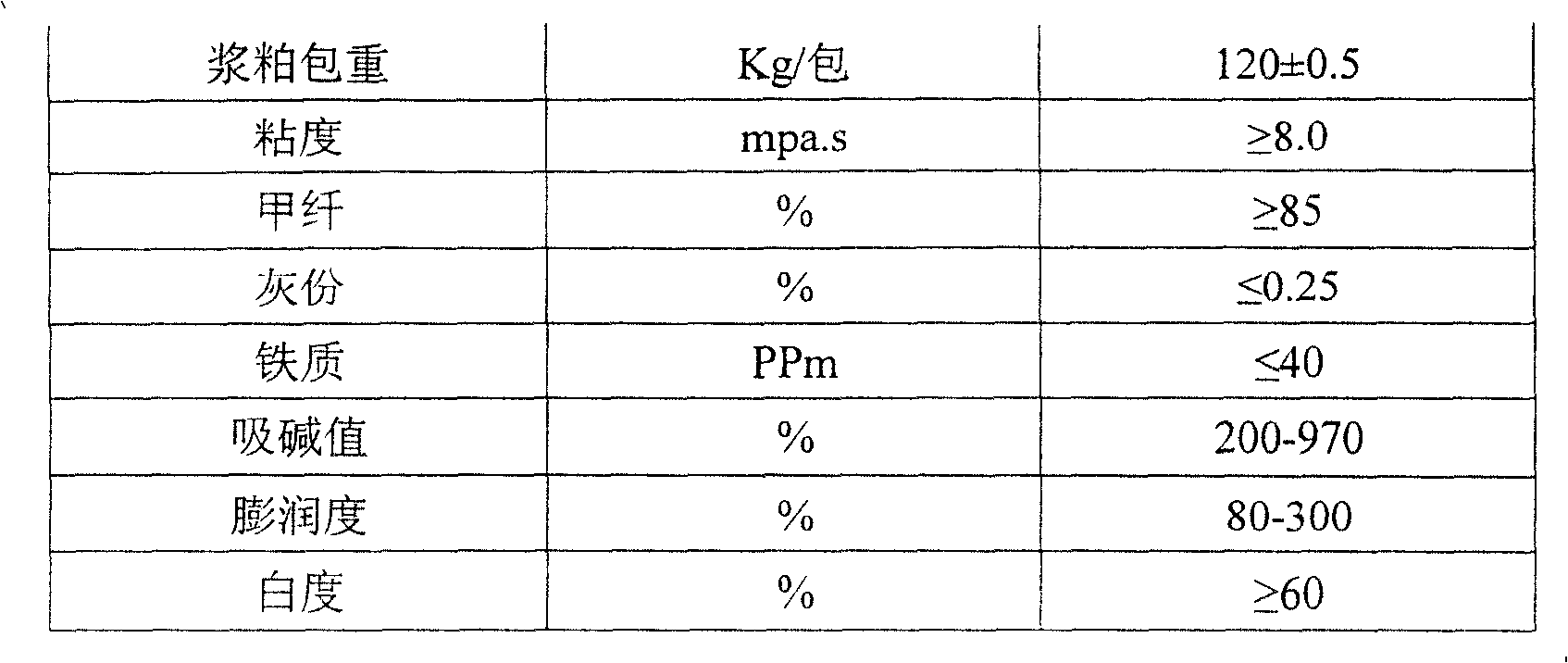

[0059] The novel composite cellulose pulp of the present invention is composed of any two or more of cotton fiber, wood fiber, hemp fiber and bamboo fiber, and its technical index is:

[0060] Ash content≤0.25%

[0061] Moisture 10.0±0.5%

[0062] Iron content≤40ppm

[0063] Fat waxy≤0.25%

[0064] Chlorine-containing substances≤0.25%

[0065] Pectin pentosan≤0.25%

[0066] Lignin≤2.0%

[0067] A cellulose ≥ 85%

[0068] Viscosity≥8.0mpa.s

[0069] Whiteness≥60%

[0070] Fixed volume weight 120~1020g / m 3

[0071] Alkaline absorption value 200-970%

[0072] Swelling degree 80-300%

Embodiment 3

[0074] The scope of application of the novel composite cellulose pulp of the present invention: acetate fiber, cupro fiber, viscose filament, tencel, viscose short filament, cellophane, carbon fiber, CMC, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com