Method for operating a network

A network and network interface technology, applied in the field of redundancy managers, can solve the problems of reducing network transmission capacity, inapplicability, etc., and achieve the effect of increasing equipment complexity, reducing device requirements and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

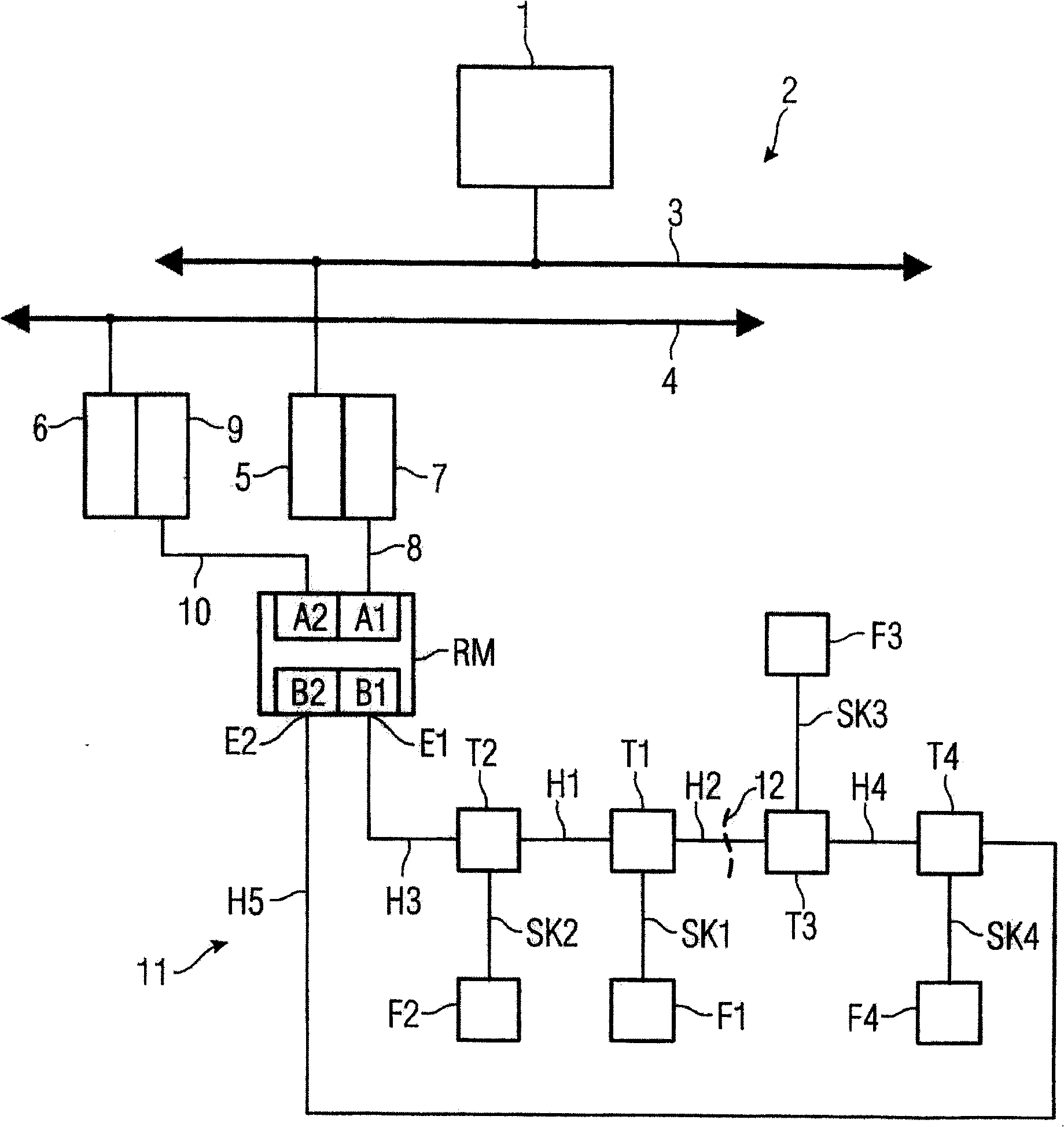

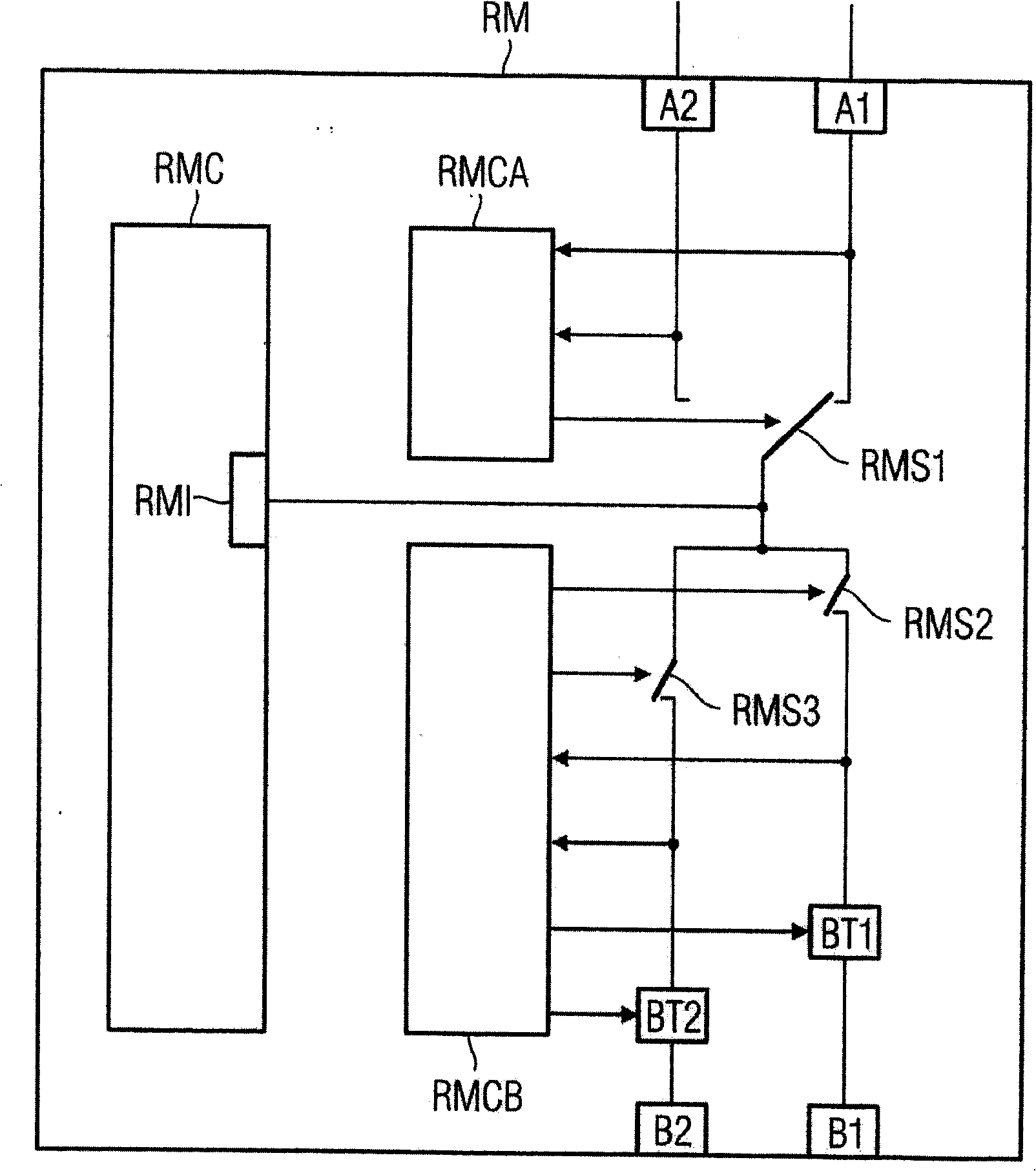

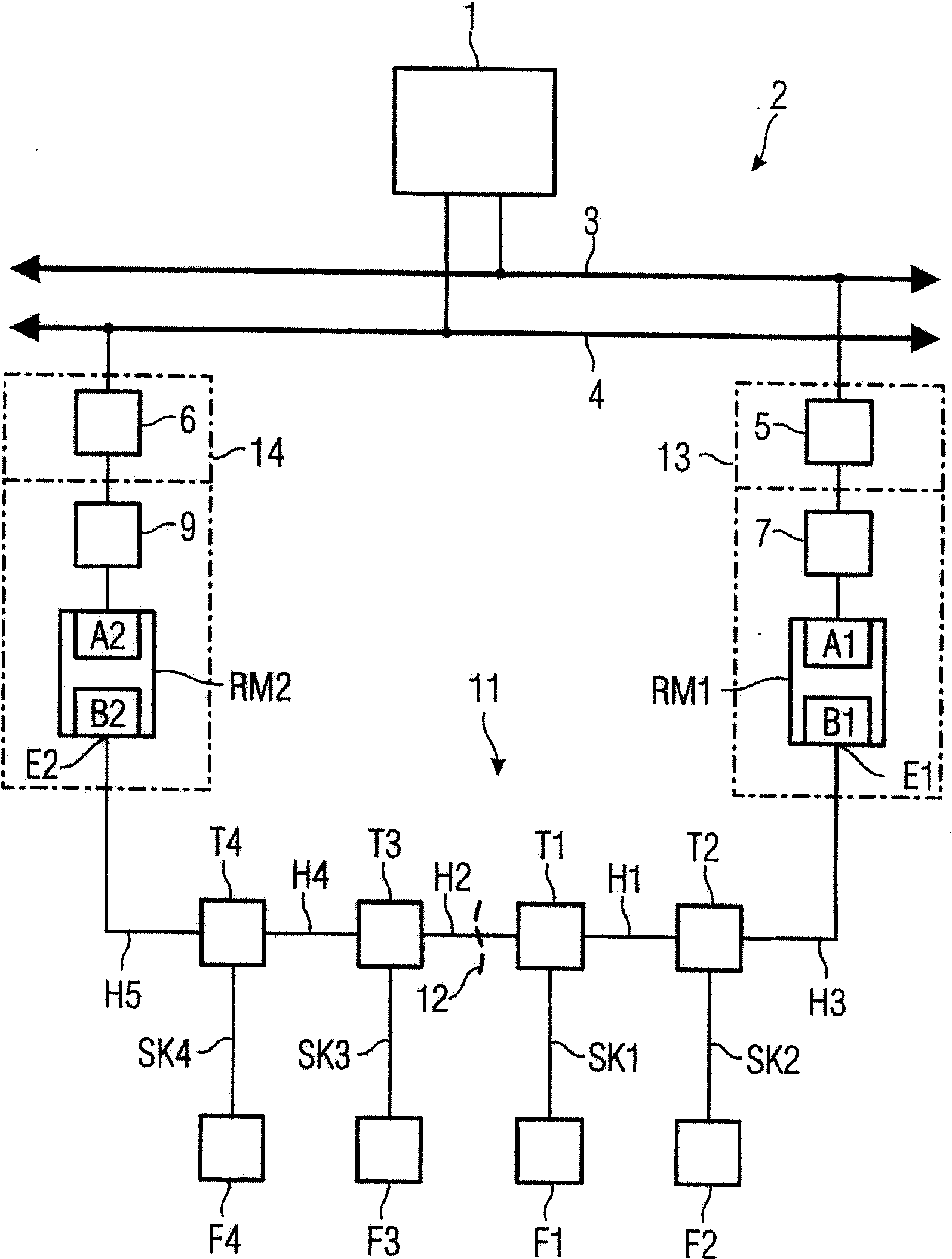

[0041] figure 1 Shown is a part of an automation technology device. A control system 1 is connected to the bus system 2 according to the distributed peripheral fieldbus standard. The bus system 2 can be of simple design or as figure 1 Redundant design shown. To each communication channel 3 , 4 of the bus system 2 is connected a link 5 or 6 respectively, in addition to other devices, such as automation devices (not shown in the figure). The link 5 is connected to a segment connector 7 which is connected via a branch cable 8 to a port A1 of a redundancy manager RM. Another link 6 is connected to another segment connector 9 which is connected via another branch cable 10 to a port A2 of the redundancy manager RM. The other two ports B1 and B2 of the redundancy manager RM are connected to a network 11 which conforms to the process automation fieldbus standard and has a line topology. A line end E1 of the network 11 is formed by the end of a trunk cable H3 connected to the port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com