Lock system of closure strucrure for fuel-tank filler pipe

A closing mechanism and closing system technology, applied in the field of locking systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

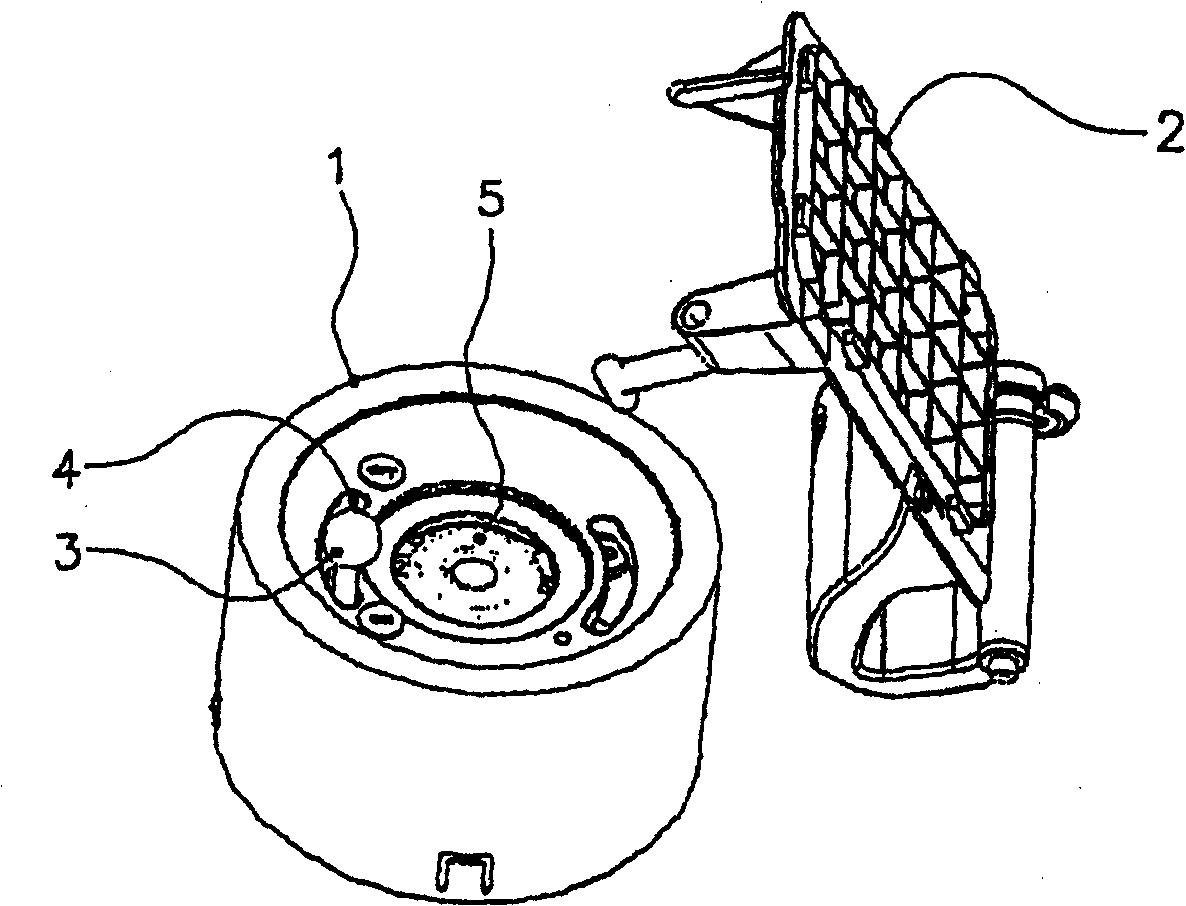

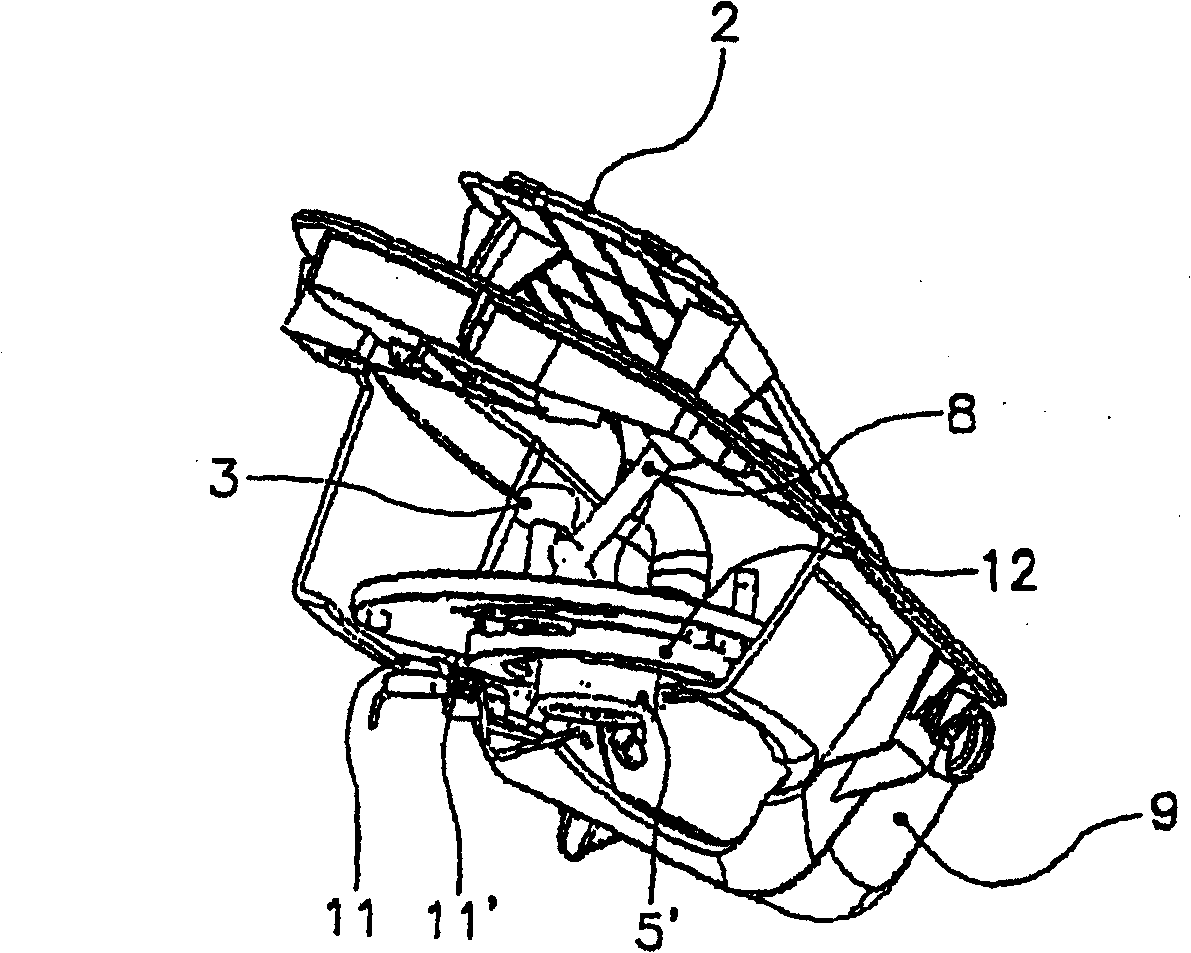

[0038] figure 1 and 2

[0039] These figures show the fitting provided with the closing mechanism 1 and the filler cap 2 in the open position. These elements are provided with a locking system comprising a lever 3 coupled to a turning ring 4 cooperating with the closure 5 by a snap-fit system. The lever 3 slides in a groove 6 formed in the cover 7 . The filling port cap 2 is joined to a joystick arm 8, which in these figures is separate from the joystick.

[0040] exist figure 1 In , the closing mechanism is in the locked position, but the cover 2 has been opened by the user.

[0041] exist figure 2 In , the closing mechanism has been unlocked by the user either manually acting on the joystick 3 directly or indirectly by controlling an actuator. In this case, the closure 5 is not visible (due to the action of the fuel injection nozzle (not shown), which is in the retracted position to fill the tank).

[0042]Locking the closing mechanism after fuel injection can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com