High-reliability locking support

A locking bracket and reliability technology, applied in the field of high-reliability locking brackets, can solve problems such as damage to the antenna mast, inconvenient operation, and failure of vehicle equipment to work normally, achieving the effect of low power consumption and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

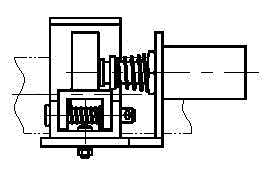

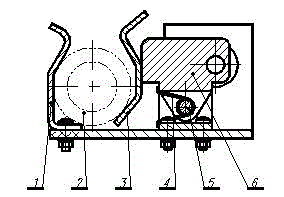

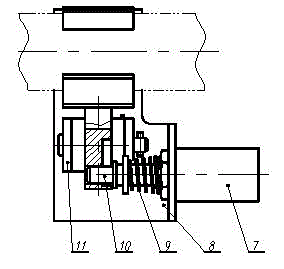

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as Figure 1 to Figure 5 shown. The high-reliability locking bracket of the present invention consists of jaw I1, jaw II3, torsion spring 4, rotating pin shaft 5, keyhole plate 6, electromagnet 7, frame body 8, electromagnet return spring 9, locking shaft 10 and lock Orifice plate mounting base 11 constitutes. Wherein, the frame body 8 is an L-shaped board, and the L-shaped board includes a vertically folded bottom board and side boards. The bottom of the jaw I1 is fixed on the top end of the bottom plate of the frame body 8 by screws, which is a fixed type. The keyhole plate 6 is provided with a waist-shaped groove 12 with a locking hole and a pin hole, and the jaw II3 is fixed on the side of the keyhole plate 6, and the jaw II3 and the keyhole plate 6 are processed into one, and can be wound around Rotate bearing pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com