Melt filter for purifying plastic melts

A technology of melt filter and filter, applied in the field of melt filter for purifying plastic melt, to achieve high pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

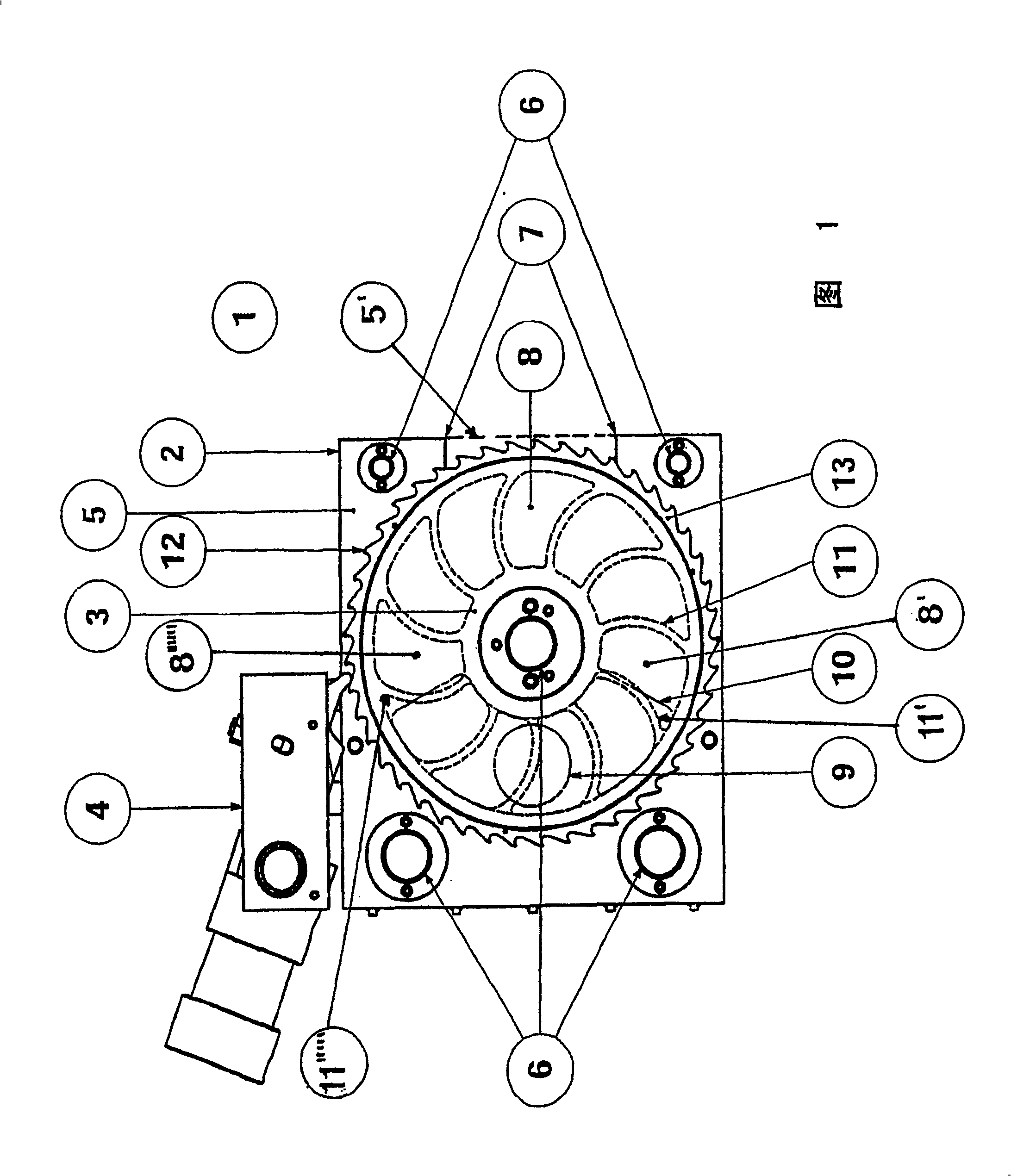

[0013] The present invention is described in detail according to the accompanying drawings. The drawing shows a melt filter 1 consisting of a housing 2 , a filter plate 3 and a pawl drive 4 . The housing 2 consists of a thin plate 5 which is connected by means of connecting elements 6 to a further thin plate 5' indicated in outline with dashed lines. Filter plate 3 is sandwiched between thin plates 5, 5'. Shown in the sheet 5 is a filter element exchange station 7 which is approximately the size of a filter element 8 . The sheet metal 5 also has a melt channel 9 which widens toward the filter plate 3 in the shape of a segment 10 .

[0014] In addition to the filter element 8 , the filter plate 3 has a partition 11 . On the circumference of the filter plate there is a pawl 12 which interacts with the pawl drive 4 . The rim 13 connects the partitions 11 to each other.

[0015] Since the filter element changing station 7 is chosen to be as small as possible, a large part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com