Guide reed swing position adjusting device of double raschel machine

A yarn guide bar and adjustment device technology, which is applied in the field of swing position adjustment devices, can solve problems such as the complexity of the yarn guide bar drive mechanism, and achieve the effect of easy adjustment and reduced swing amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

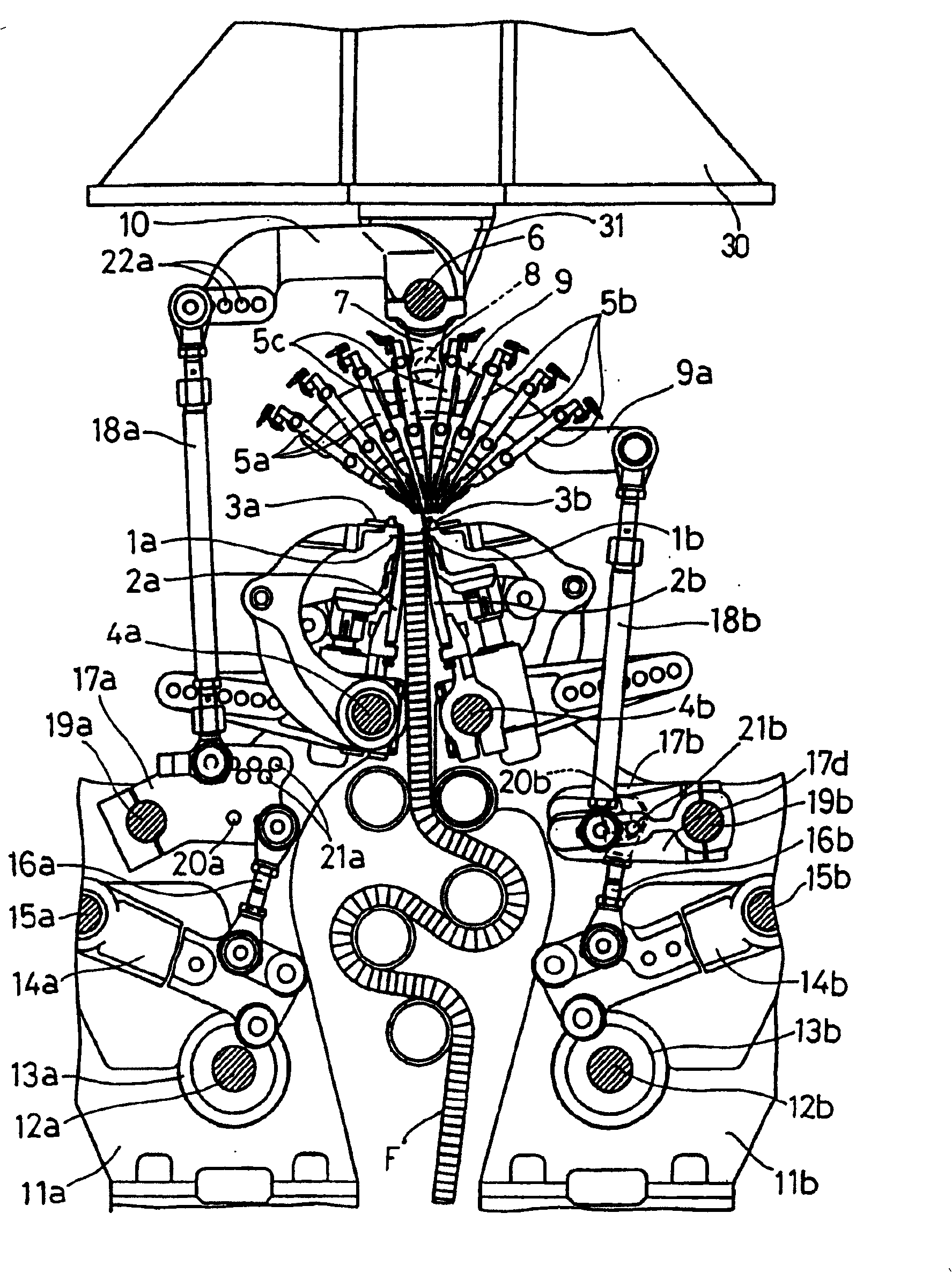

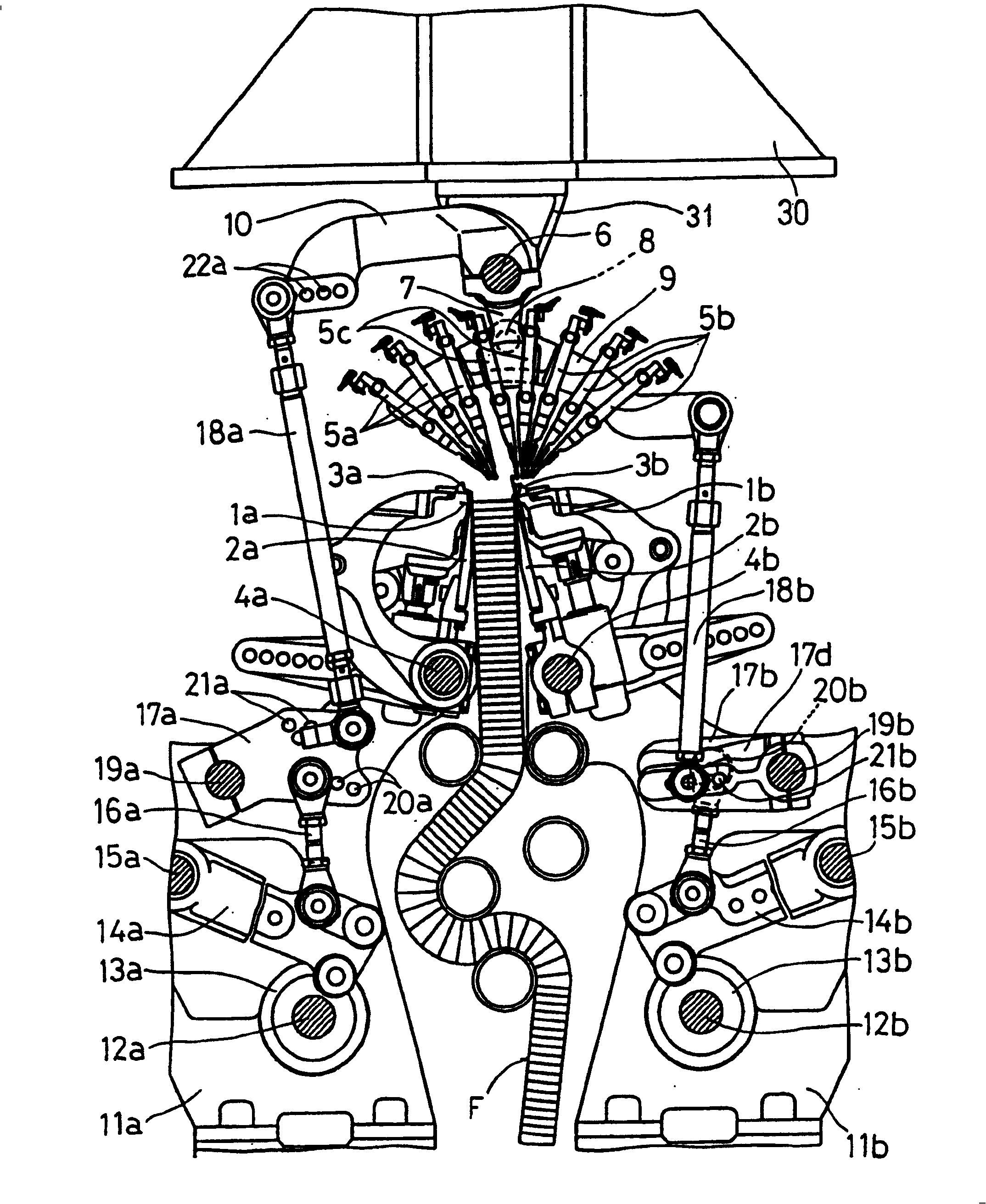

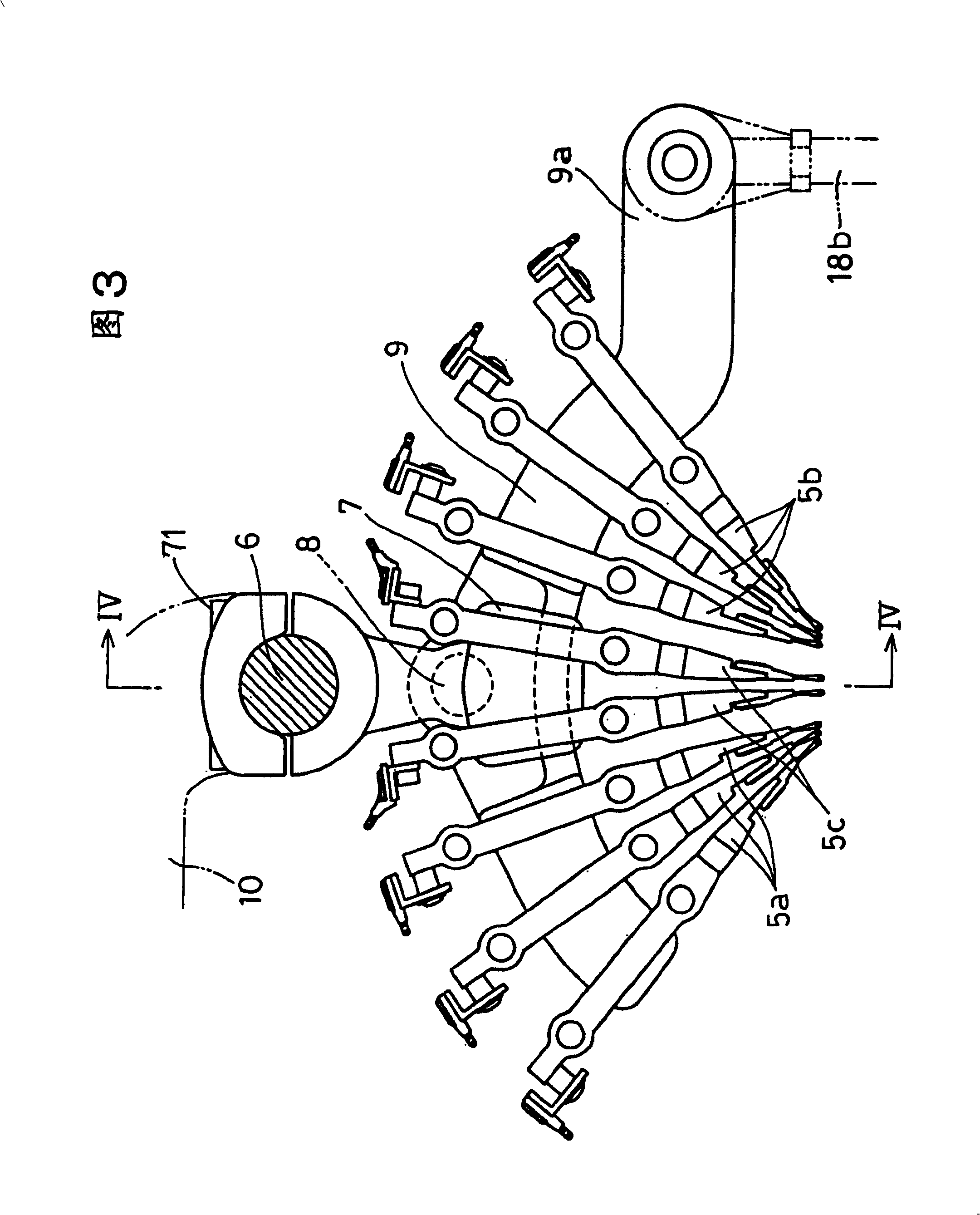

[0023] Next, according to the embodiment shown in the drawings, the embodiment of the device for adjusting the swinging position of the guide bar in the double-needle bed Raschel warp knitting machine of the present invention will be described.

[0024] figure 1 It is a schematic cross-sectional view of a double-needle-bed Raschel warp knitting machine, seen from the side, showing a swing position adjusting device for a guide bar of the present invention, figure 2 It is a cross-sectional view of the double-needle bed Raschel warp knitting machine as above, when the needle cylinder interval, that is, the interval between the front and rear needle groove plates, is enlarged. Fig. 3 is the enlarged sectional view of the guide bar part of the device of the previous figure, Figure 4 It is a partial cross-sectional view of line IV-IV in the preceding figure.

[0025] In the figure, 1a is the row of knitting needles at the front, and 1b is the row of knitting needles at the rear,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com