Equipment of wave power generation

A wave power generation, non-metallic technology, applied in electromechanical devices, ocean energy power generation, electrical components, etc., can solve the problems of difficult maintenance, high production cost, oil leakage in pipelines, etc., and achieve easy production, low cost, and ensure continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

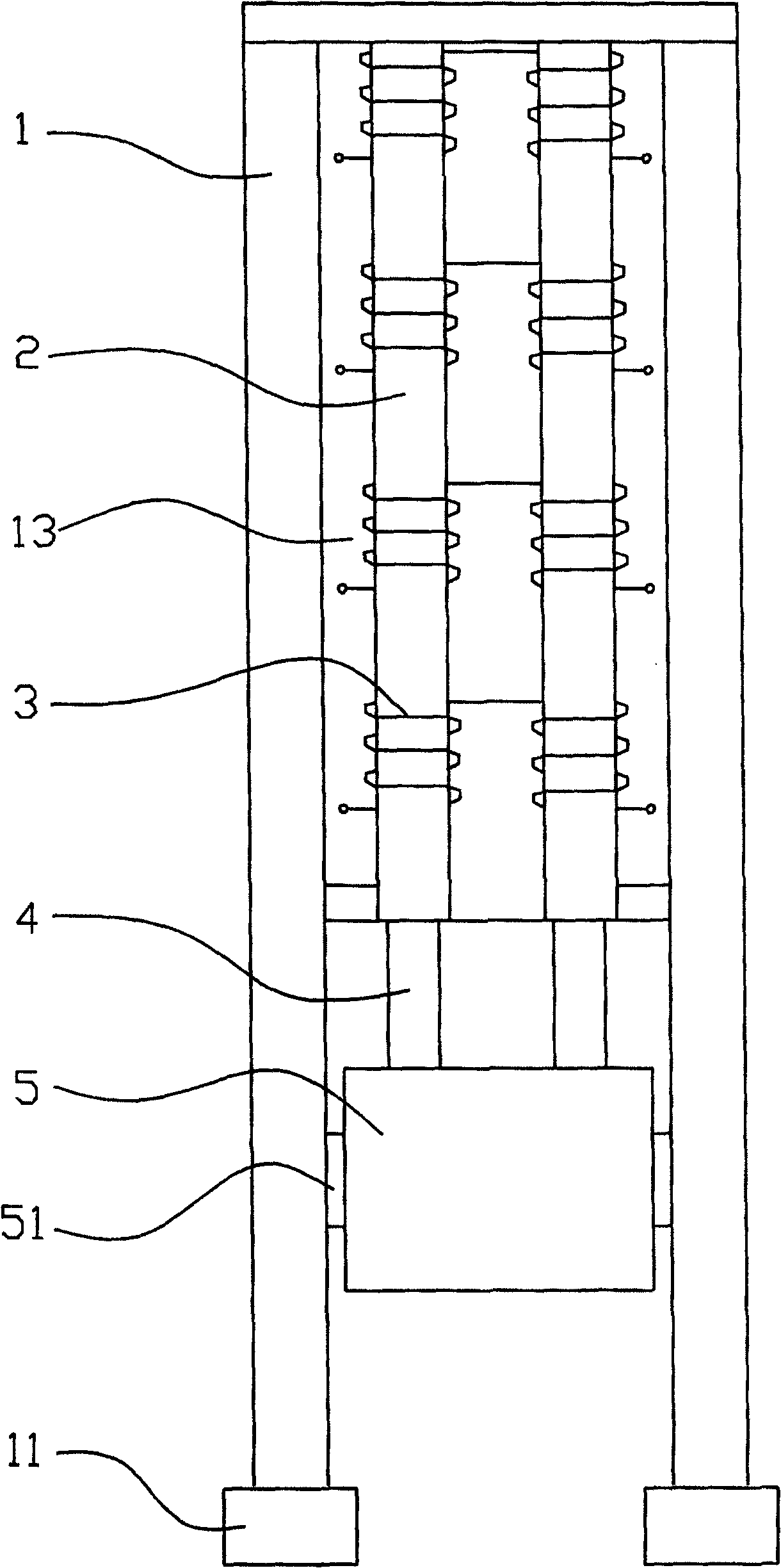

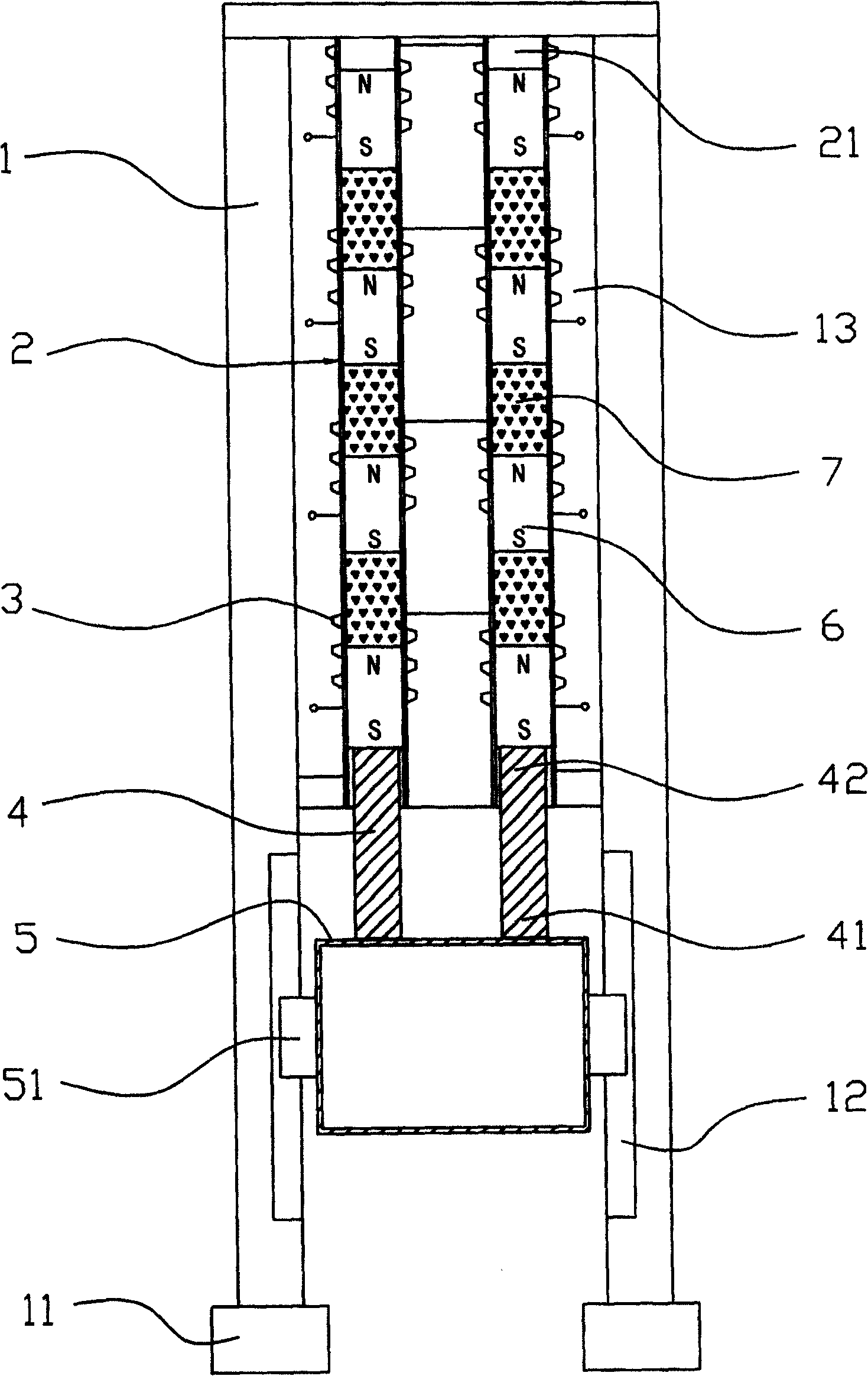

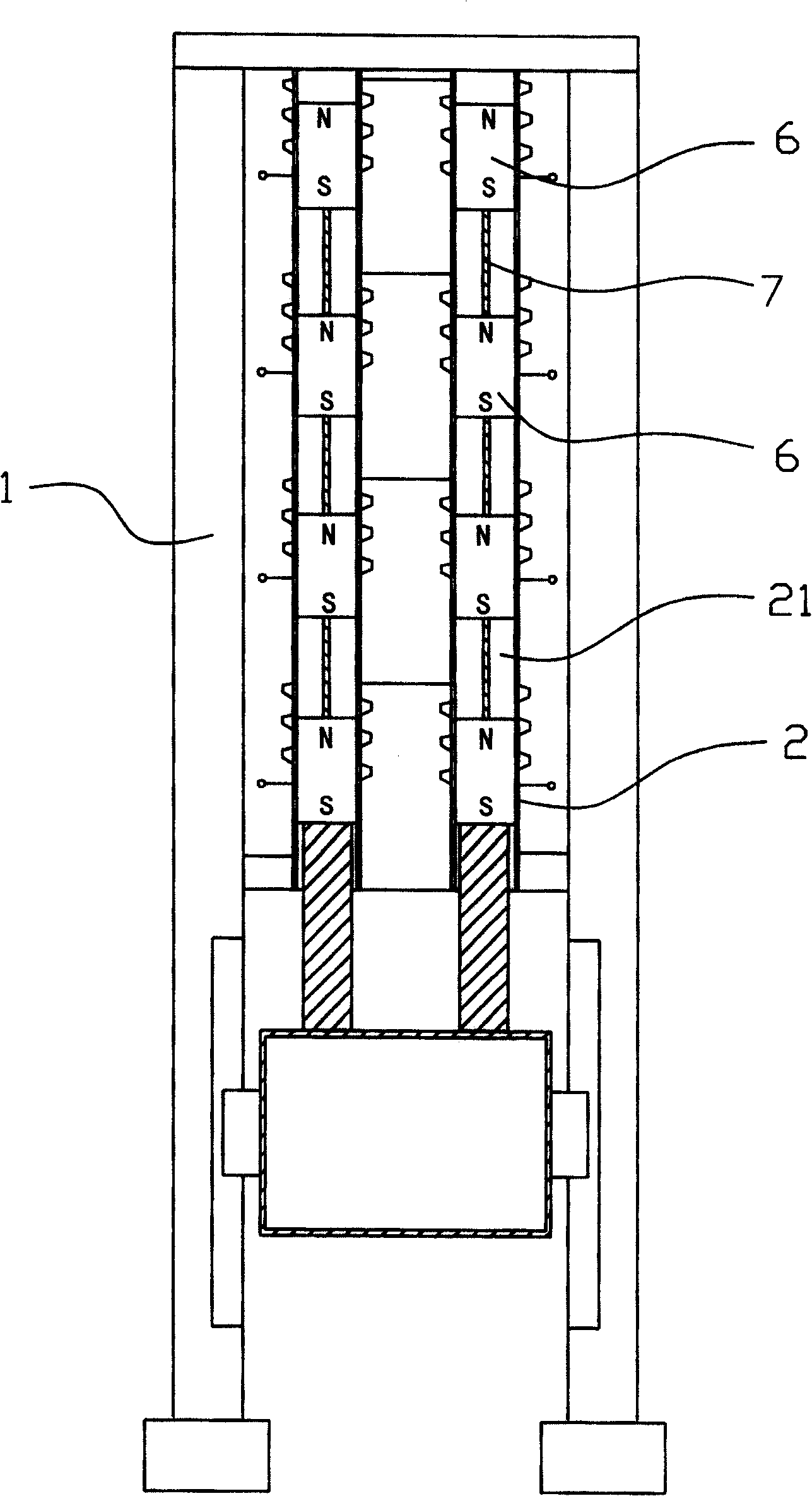

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] like figure 1 , figure 2 and image 3 As shown, the wave power generation device of this embodiment includes a buoy 5 and a push rod 4 connected to the buoy 5. Two protruding sliders 51 extend from both ends of the buoy 5, and the two sliders 51 can slide up and down respectively. The ground is stuck in the vertical sliding groove 12 opened on the inner wall of the fixed bracket 1 and corresponding to the two sliding heads 12 . The foot 11 of the fixed support 1 extends into the seabed and is fixed on the seabed, and its inner cavity 13 communicates with the seawater, and a vertical non-metallic sliding pipe 2 is fixed in the inner cavity 13 on the upper part of the fixed support 1. In this non-metallic Coils 3 are wound at intervals on the outer circumference of the slide tube 2, and the two ends of the coil 3 are respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com